Nanoreactor, preparation method and application thereof

A nano-reactor, nano-particle technology, applied in pharmaceutical formulations, metal processing equipment, medical preparations with non-active ingredients, etc., can solve the problems such as the inability to achieve controlled release of silver, and achieve low systemic toxicity and high safety. , The effect of preparation technology is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Preparation of Zeolite Imidazolate Framework-8(ZIF-8)1#

[0077] 0.89g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 30 mL of methanol to form a solution. 20 mL of methanol containing 1.97 g of 2-methylimidazole was poured into Zn(NO 3 ) 2 in solution. The mixture was kept at room temperature for 24 hours. The resulting white precipitate was collected by centrifugation, washed three times with methanol, and finally placed in an oven at 60° C. to dry overnight.

[0078] Preparation of intermediate product A1

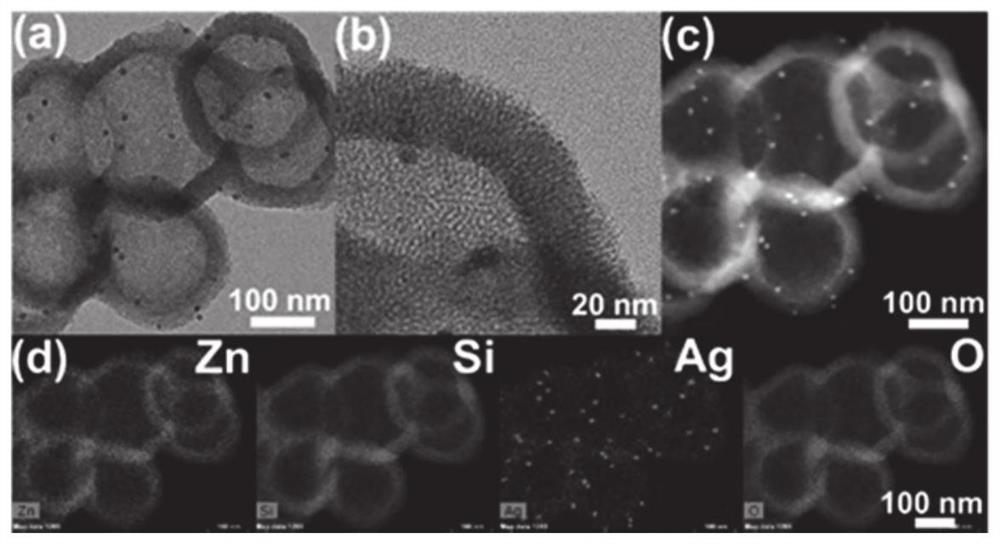

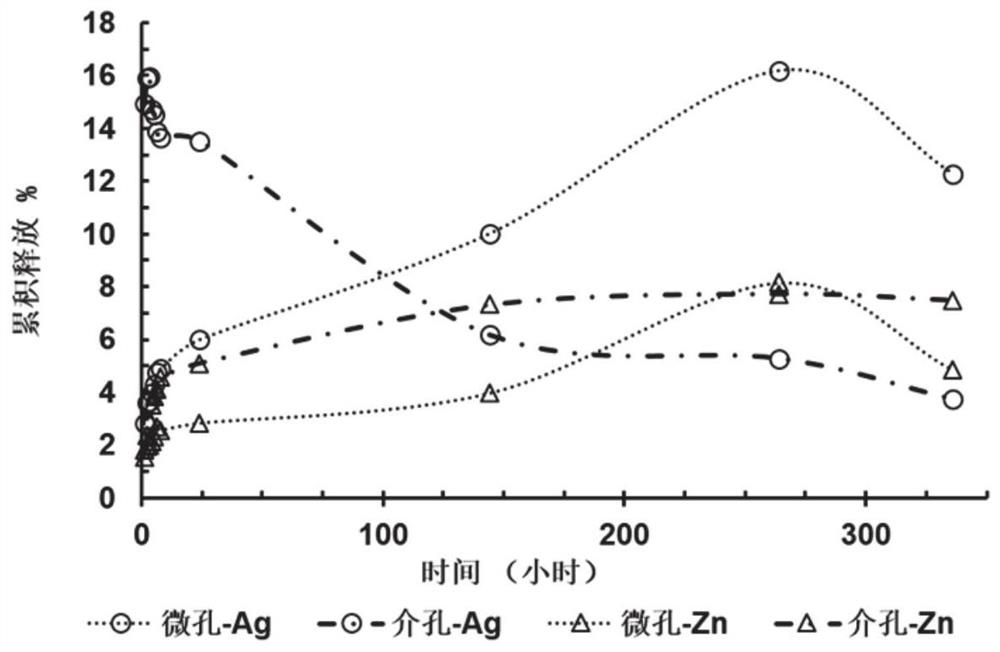

[0079] Dip sample 1# into 10mL methanol solution containing 40μmol metal silver ions, and stir evenly. Then 1 mL of methanolic solution containing 40 mg of sodium borohydride was added to the mixture with vigorous stirring. After reacting for 30 minutes, the product was collected by centrifugation, washed several times with ethanol, and dried overnight at 60°C to synthesize sample A1. The intermediate product A1 was nanoparticles loaded with metallic silver on ZIF-...

Embodiment 2

[0086] The zeolite imidazolate framework-8 (ZIF-8) used in this example is the sample 1# prepared in Example 1.

[0087] Preparation of intermediate product A2

[0088] Immerse sample 1# in 10mL of methanol solution containing 20μmol metal copper ions, and stir evenly. Then 1 mL of methanolic solution containing 10 mg of sodium borohydride was added to the mixture under vigorous stirring. After reacting for 30 minutes, the product was collected by centrifugation, washed several times with ethanol, and dried overnight at 60° C. to synthesize intermediate product A2.

[0089] Preparation of nanoreactor C2 (mesoporous)

[0090] 0.1 g of cetyltrimethylammonium bromide was dissolved in a mixture of water (20 mL) and ethanol (8 mL). Then, add ammonia solution (NH 4 OH, 0.2 mL, 25 wt%) and stirred at room temperature, then sample A2 was added. After stirring, 450 μL of ethyl orthosilicate solution was added to the suspension. The mixture was stirred at room temperature for 24 h...

Embodiment 3

[0094] The zeolite imidazolate framework-8 (ZIF-8) used in this example is the sample 1# prepared in Example 1.

[0095] Preparation of intermediate product A3

[0096] Dip sample 1# into 10mL methanol solution containing 40μmol metal silver ions, and stir evenly. Then 1 mL of methanolic solution containing 20 mg of sodium borohydride was added to the mixture under vigorous stirring. After reacting for 30 minutes, the product was collected by centrifugation, washed several times with ethanol, and dried overnight at 60° C. to synthesize intermediate product A3.

[0097] Preparation of nanoreactor C3 (mesoporous)

[0098] 0.5 g of cetyltrimethylammonium bromide was dissolved in a mixture of water (20 mL) and ethanol (8 mL). Then, add ammonia solution (NH 4 OH, 0.3mL, 25wt%) and stirred at room temperature, then added Ag&ZIF-8 nanoparticles. After stirring, 330 µL of ethyl orthosilicate solution was added to the suspension. The mixture was stirred at room temperature for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com