Preparation method of grease rich in OPL and OPO and product thereof

A technology of oil and oleic acid, which is applied in the field of preparation of structural esters and food additives, can solve problems such as the inability to realize the regulation of OPO/OPL ratio, the difficulty of obtaining OPL and OPO oil, and the inability to obtain raw materials directly, so as to ensure product quality and quality Effects of stability, ease of scale-up and automation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

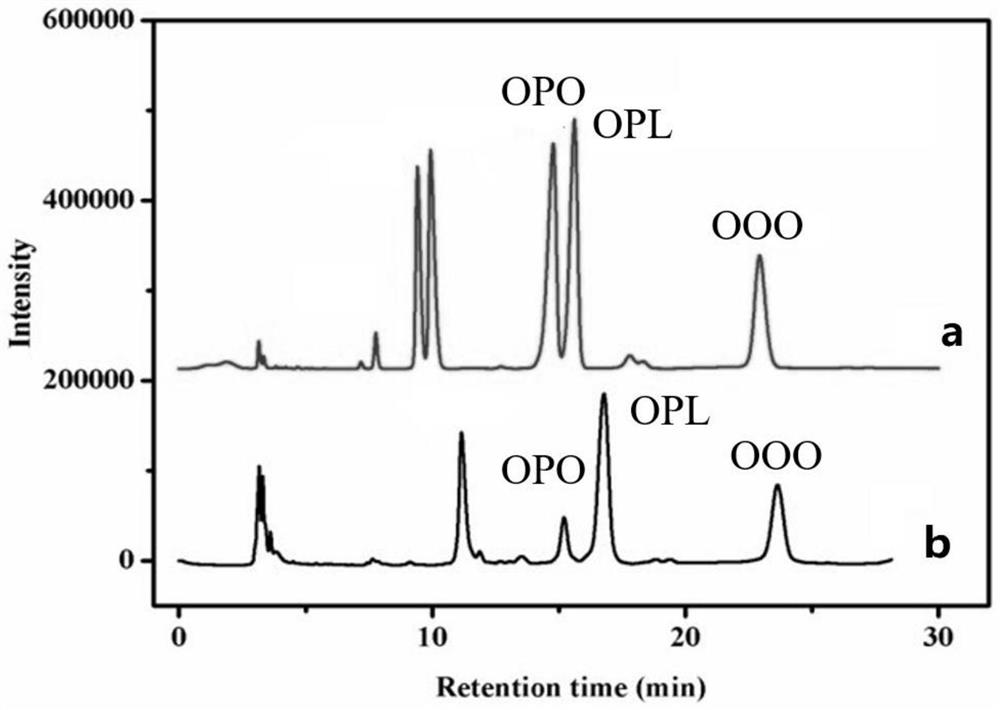

Image

Examples

Embodiment 1

[0027] A preparation method rich in OPO and OPL grease, specifically comprising the steps of:

[0028] (1) Preparation of PPP structural ester: with glycerol: the molar ratio of palmitic acid is 1:5, add catalyst p-toluenesulfonic acid (accounting for 0.5% of the total weight of the reaction substrate) to be placed in the flask, stirring speed 200rpm, reaction temperature 90 ℃, the reaction time is 2 hours, during the reaction, nitrogen gas is continuously fed as a protective gas, and after the reaction is completed, the high-purity PPP raw material is obtained by separation and purification;

[0029] Through liquid phase detection, the content of PPP in the reaction product is 85% (content in mass percent);

[0030] (2) Prepare the structural ester of OPO: according to PPP: the molar ratio of oleic acid is 1:3, PPP raw material and oleic acid are mixed, add substrate quality 3% Candida antarctica lipase and substrate quality 10 times of n-hexane alkanes, at 50°C, with a stir...

Embodiment 2

[0035] A preparation method rich in OPO and OPL grease, specifically comprising the steps of:

[0036] (1) Preparation of PPP structural ester: use palm stearin with a palmitic acid content of more than 70% as raw material, add chemical catalyst sodium methylate, carry out intramolecular rearrangement reaction, and obtain triglyceride rich in palmitic acid after separation and purification after the reaction is completed ester raw material;

[0037] (2) Preparation of OPO structural ester: According to the molar ratio of PPP: oleic acid is 1:5, mix the PPP raw material and oleic acid, add 5% Candida lipolytica lipase and isooctane, and stir at 60°C The transesterification reaction occurred at a rate of 200rpm for 8 hours, and the oil rich in OPO was obtained after molecular distillation and purification to remove fatty acids; the content of OPO in the reaction product was 48% through liquid phase detection;

[0038](3) Preparation of structural esters rich in OPO and OPL: the...

Embodiment 3

[0040] A preparation method rich in OPO and OPL grease, specifically comprising the steps of:

[0041] (1) Preparation of PPP structure ester: with embodiment 1

[0042] (2) Preparation of OPO: According to PPP: the molar ratio of oleic acid is 1:8, PPP raw material and oleic acid are mixed, add 8% Candida lipolytica lipase and buffer emulsion (pH 7.0, substrate total mass 2 %), at 70 DEG C, the transesterification reaction 3h takes place under the stirring rate of 300rpm, after purification by molecular distillation, after removing the fatty acid, the oil rich in OPO is obtained; through liquid phase detection, the content of OPO in the reaction product is 65%;

[0043] (3) Preparation of structural esters rich in OPO and OPL: the OPO obtained above is mixed with linoleic acid at a molar ratio of 1:8, and 8% Burkholderia cepacia lipase and buffer emulsion (pH 7.0, 2% of the total mass of the substrate), at 70° C., a transesterification reaction occurred at a stirring rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com