Elastic solid electrolyte material and preparation method thereof

A solid electrolyte and elastic technology, applied in solid electrolyte, electrolyte battery manufacturing, electrolyte and other directions, can solve the problems of low power density, low energy density, poor lithium conductivity, etc., to avoid battery short circuit, simple preparation process, and expand application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

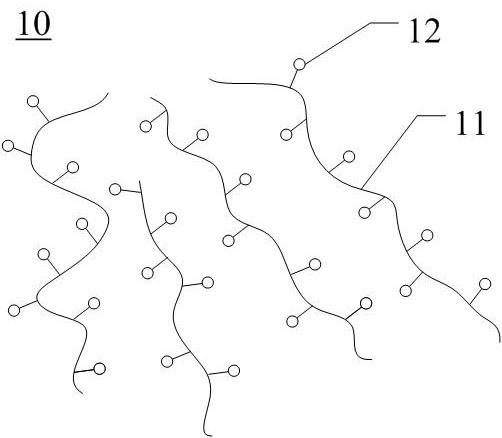

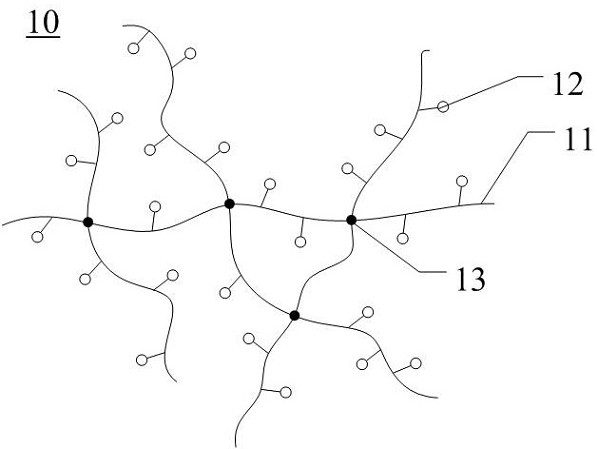

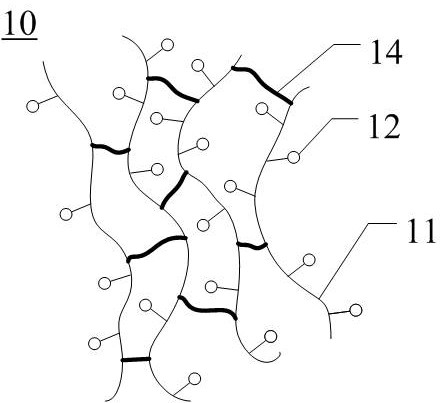

[0046] This embodiment provides an elastic solid electrolyte material, including a rubber matrix and a metal salt, the metal salt is dispersed in the rubber matrix, and the rubber matrix is obtained by reacting a rubber material with an ionic liquid, wherein both the rubber material and the ionic liquid contain Unsaturated chemical bonds, the molecules of the ionic liquid are grafted on the molecular chains of the rubber material through the addition reaction of the unsaturated chemical bonds to obtain a rubber matrix. Such as Figure 1~4 As shown, the schematic diagrams of the structures of four different rubber matrices are given, among which, figure 1The molecular chain 11 of the rubber material in the middle rubber matrix 10 is a linear structure (such as natural rubber), and the molecule 12 of the ionic liquid is grafted on the molecular chain 11; figure 2 The molecular chains 11 of the rubber material in the middle rubber matrix 10 are cross-linked with each other, ...

Embodiment 2

[0054] This embodiment provides a method for preparing an elastic solid electrolyte material, including:

[0055] Mixing step: dissolving components including rubber material, ionic liquid, metal salt and initiator in a solvent to form a mixed fluid, wherein both the rubber material and the ionic liquid contain unsaturated chemical bonds;

[0056] Curing step: the molecules of the ionic liquid are grafted onto the molecular chains of the rubber material through reaction to form an elastic solid electrolyte material.

[0057] When both the rubber material and the ionic liquid contain unsaturated chemical bonds, under the action of the initiator (or vulcanizing agent), the unsaturated chemical bonds of the ionic liquid and the unsaturated chemical bonds on the molecular chain of the rubber material undergo an addition reaction to realize the The molecular chains of the rubber material are grafted, and at the same time, the molecular chains of the rubber material are cross-linked...

Embodiment 3

[0070] In order to better illustrate the technical characteristics of the present invention, this embodiment provides a specific method for preparing an elastic solid electrolyte material, including the following steps:

[0071] 1) Mixing step: natural rubber, 1-allyl-3-methylimidazole bistrifluoromethanesulfonyl imide salt, bistrifluoromethanesulfonyl imide with a mass ratio of 1:0.5:0.0.5:0.02 Lithium amide and sulfur are dissolved in benzene and acetone with a volume ratio of 1:1 to obtain a mixed fluid;

[0072] 2) Solidification step: heat the mixed fluid obtained in step 2) to 140°C in a protective gas argon atmosphere, keep it warm for 0.5h, and cool it down to normal temperature after the reaction is completed to obtain an elastic solid electrolyte material.

[0073] The elastic solid electrolyte material obtained in this embodiment has a lower curing temperature and a shorter curing time, and the addition reaction between the double bond in the ionic liquid and the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com