Method for preparing nanocellulose microfibrils through pretreatment of ternary eutectic solvent

A low eutectic solvent and nanocellulose technology, which is applied in fiber raw material processing, textile and papermaking, etc., can solve problems such as poor effect, and achieve the effects of simple operation, shortened pretreatment time, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Synthesis of ternary deep eutectic solvent: Weigh 28g choline chloride, 36g oxalic acid, 9.64g aluminum trichloride, mix the three and stir at 70°C until a uniform transparent liquid is formed to obtain Ternary deep eutectic solvent;

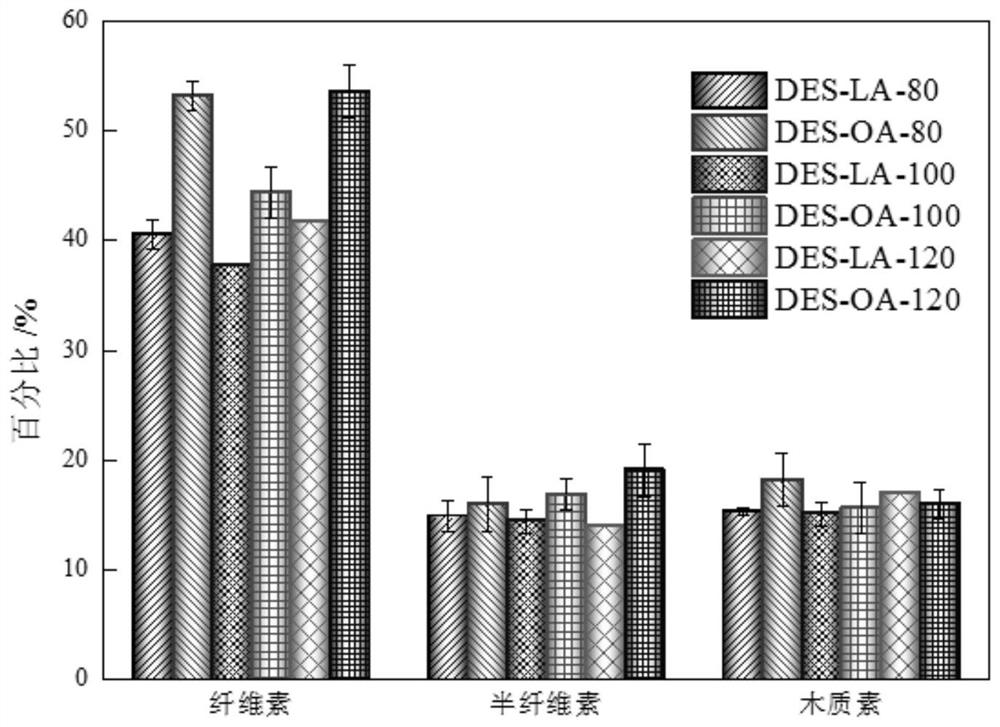

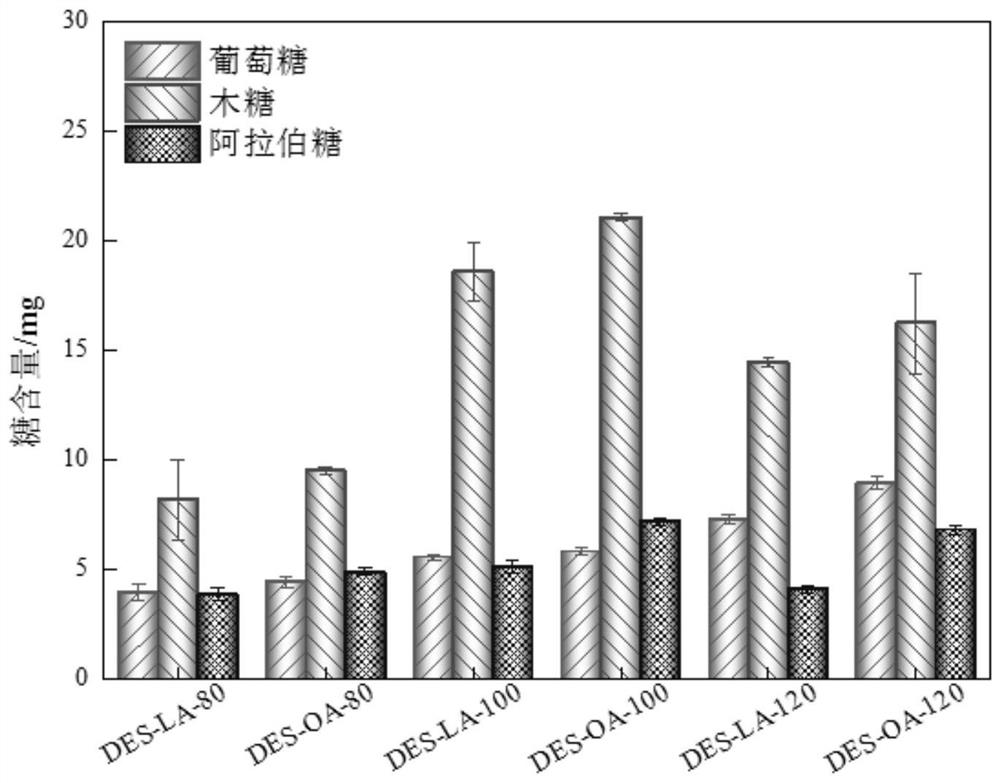

[0042](2) Pretreatment: Add 0.5g bagasse to the microwave digestion tank, then add 5g ternary deep eutectic solvent, and react at 80°C for 20min; for the accuracy of the experimental data, three parallel experiments were performed for each group of experiments; After completion, immediately put into an ice-water bath to stop the reaction, separate the solid from the liquid, dilute the liquid part by 20 times with distilled water, let it stand, and analyze and measure the sugar content in the reaction solution by HPLC. The solid part was washed with acetone aqueous solution (volume ratio of acetone and water 50:50, v / v) until the filtrate was colorless, and finally the solid part was freeze-dried to obtain pretreated bagasse. The cont...

Embodiment 2

[0045] (1) Synthesis of ternary deep eutectic solvent: take by weighing 28g choline chloride, 36g lactic acid, 9.64g aluminum trichloride, mix the three and stir at 70°C until a uniform transparent liquid is formed to obtain Ternary deep eutectic solvent;

[0046] (2) Pretreatment: Add 0.5g bagasse to the microwave digestion tank, then add 5g ternary deep eutectic solvent, and react at 100°C for 20min; for the accuracy of the experimental data, each group of experiments is done in three parallels; After completion, immediately put into an ice-water bath to stop the reaction, separate the solid from the liquid, dilute the liquid part by 20 times with distilled water, let it stand, and analyze and measure the sugar content in the reaction solution by HPLC. The solid part was washed with acetone aqueous solution (volume ratio of acetone and water 50:50, v / v) until the filtrate was colorless, and finally the solid part was freeze-dried to obtain pretreated bagasse. The contents o...

Embodiment 3

[0049] (1) Synthesis of ternary deep eutectic solvent: Weigh 28g choline chloride, 36g oxalic acid, 9.64g aluminum trichloride, mix the three and stir at 70°C until a uniform transparent liquid is formed to obtain Ternary deep eutectic solvent;

[0050] (2) Pretreatment: Add 0.5g bagasse to the microwave digestion tank, then add 5g ternary deep eutectic solvent, and react at 120°C for 20min; for the accuracy of the experimental data, three parallel experiments were performed for each group of experiments; After completion, immediately put into an ice-water bath to stop the reaction, separate the solid from the liquid, dilute the liquid part by 20 times with distilled water, let it stand, and analyze and measure the sugar content in the reaction solution by HPLC. The solid part was washed with acetone aqueous solution (volume ratio of acetone and water 50:50, v / v) until the filtrate was colorless, and finally the solid part was freeze-dried to obtain pretreated bagasse. The co...

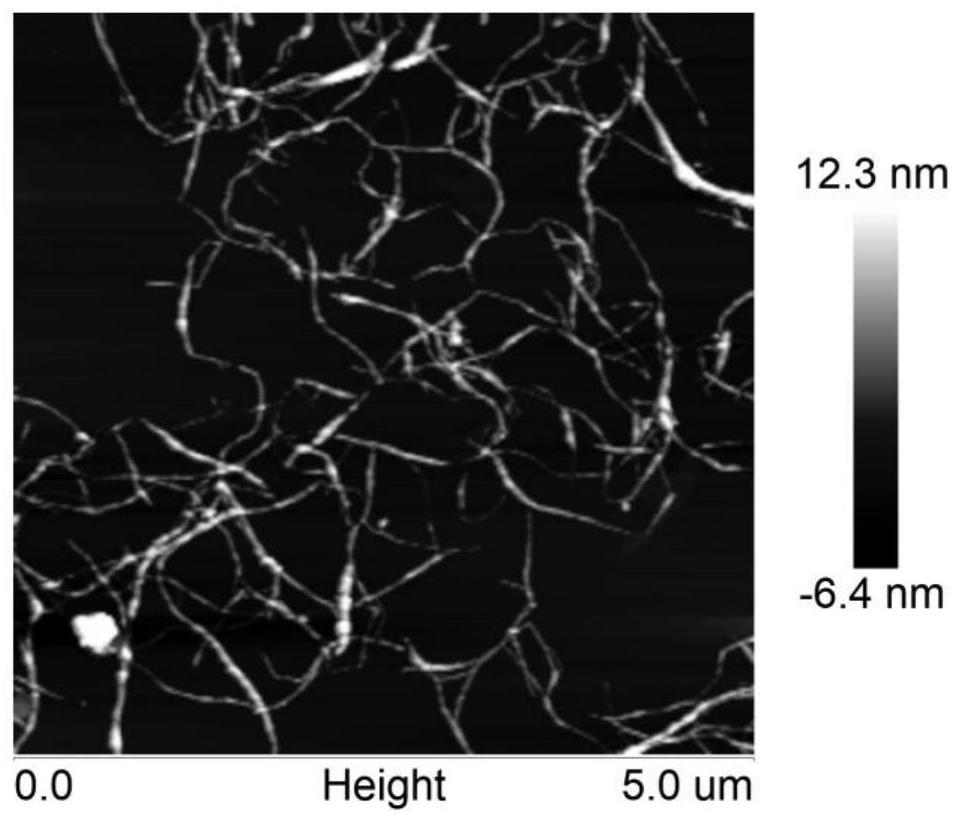

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com