Preparation method of high-purity glycerophosphate diester

A glycerophosphodiester, high-purity technology, applied in the field of genetic engineering of enzymes, can solve the problems of complex process, many steps, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Treatment of purified pfGDPD for hydrolysis of lysophospholipids

[0020] (1) Treatment of pfGDPD with a metal ion chelator: EDTA-2Na with a final concentration of 20 mM was added to the purified pfGDPD, and it was left to stand at 4° C. for 2 h.

[0021] (2) Hydrolyzed lysophospholipids of pfGDPD treated with EDTA-2Na: dissolve lysophosphatidylcholine LPC (16:0) with borate buffer (pH 8.0), add pfGDPD treated in step (1), and shake at constant temperature The reaction was carried out at 30 °C in the instrument at 300 r / min for 4 h.

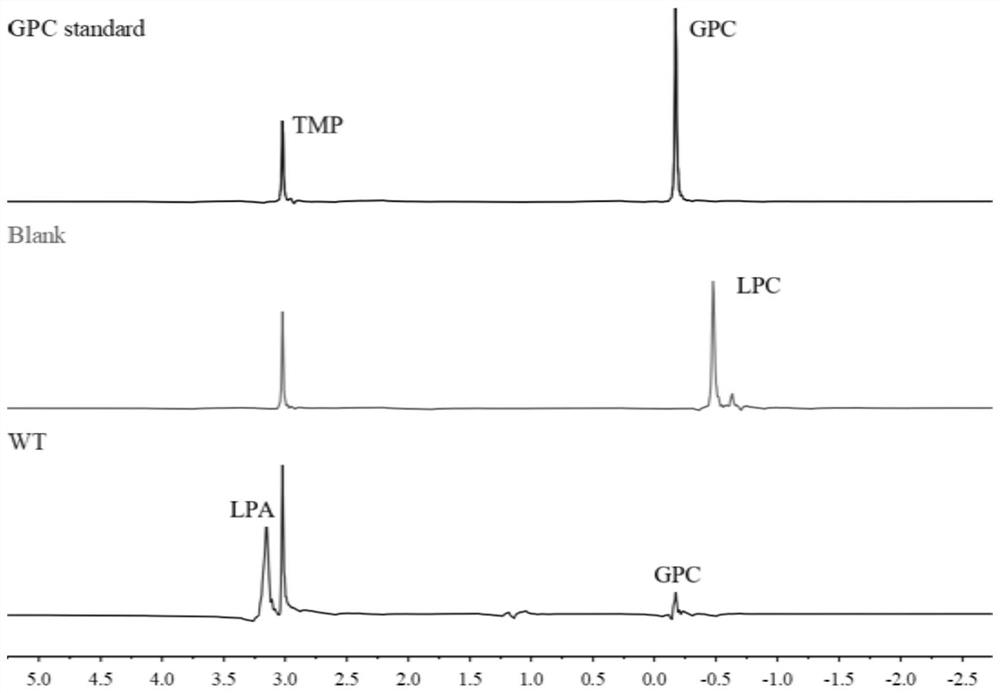

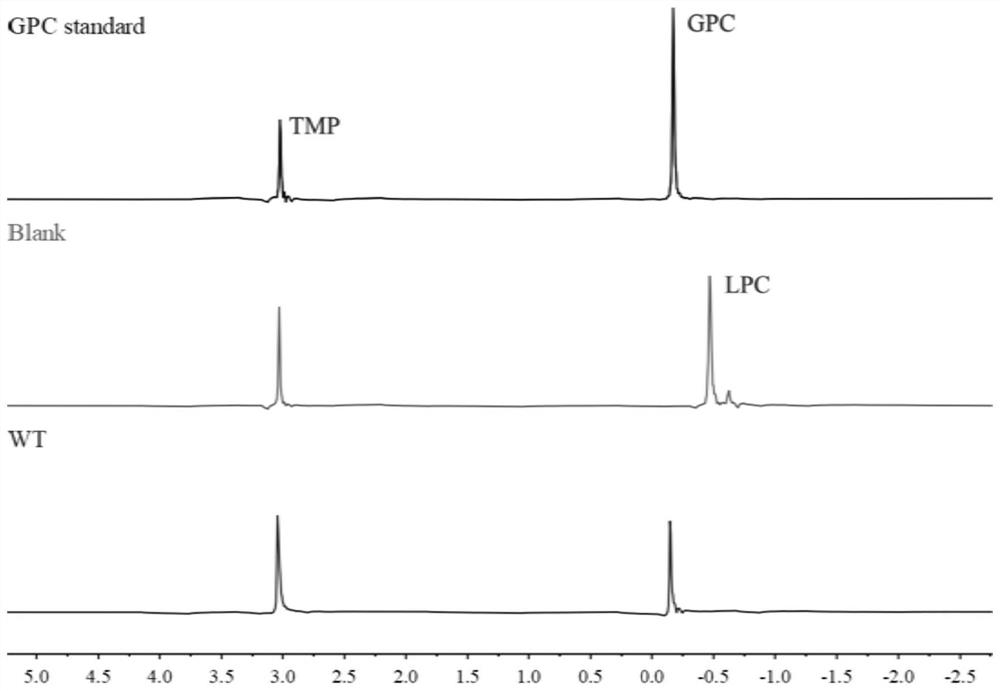

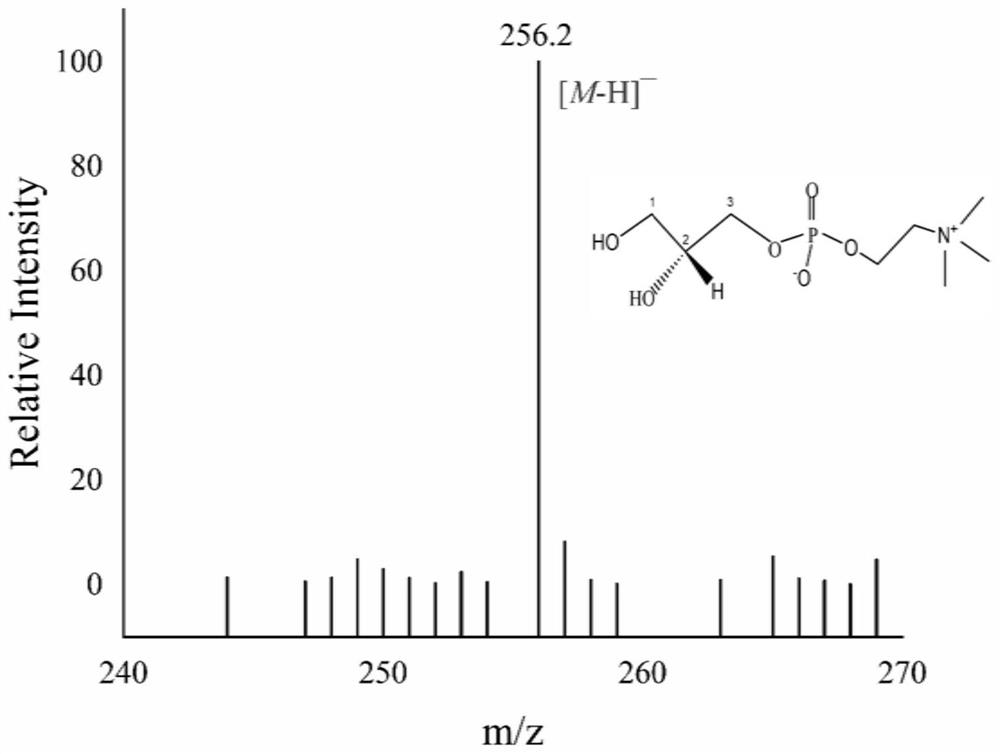

[0022] Get the product after reaction and carry out nuclear magnetic resonance detection, the result shows ( figure 2 ) The ability of wild-type pfGDPD to catalyze the hydrolysis of lysophospholipid substrates after treatment with metal ion chelator was significantly enhanced. The reaction system only contained GPC, and the formation of LPA(16:0) and the residue of LPC(16:0) were not detected. Glycerophosphoric acid diester (...

Embodiment 2

[0025] Detection of GPC generation by hydrolyzing lysophospholipids after treating pfGDPD with different metal ion chelators: adding disodium EDTA, aminotriacetic acid, diethylenetriaminepentaacetic acid and Among its sodium salt, citric acid and its sodium salt, tartaric acid and its sodium salt, gluconic acid and its sodium salt, after standing at 4 °C for 2 hours, the treated pfGDPD was taken to hydrolyze lysophospholipids, respectively. The reaction system and reaction conditions Same as Example 1. The reaction product was taken for nuclear magnetic resonance detection. The results showed that there was no significant difference in the treatment effect of different metal ion chelating agents, and the conversion rate of glycerophosphoric acid diester (GPC) during the reaction process could reach 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com