Fluorine-containing weak coordination anion modified copper-based catalyst for acetylene hydrochlorination reaction as well as preparation method and application thereof

A technology of acetylene hydrochlorination and anion modification, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, hydrogen halide addition preparation, etc., can solve the problems of poor stability and low activity of copper-based catalysts, and achieve improved stability properties, improving the activity of copper-based catalysts, and enhancing the acidity of Lewis acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

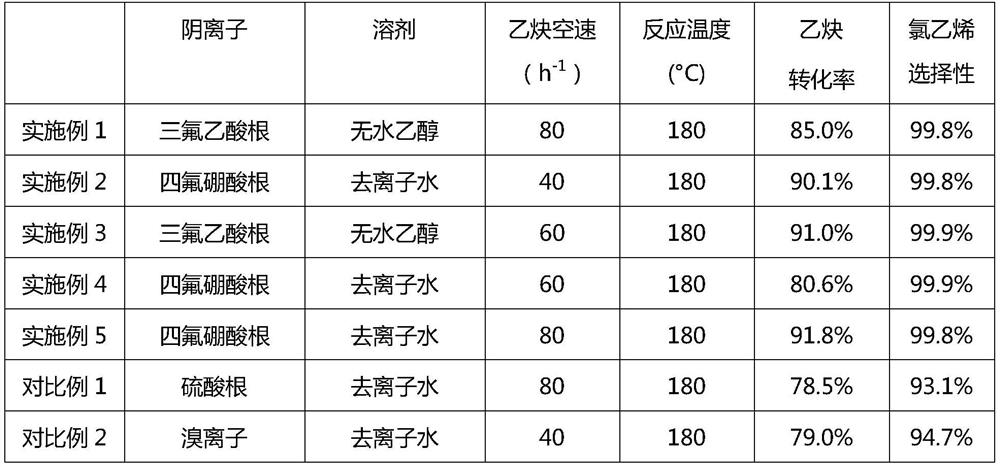

Examples

Embodiment 1

[0043] (1) 10.06 g of tetrahydrate trifluoroacetate is dissolved in 19.00 g of anhydrous ethanol to obtain a bronze ion and trifluoroacetate anion of the impregnation liquid;

[0044](2) Immerse the above impregnation liquid onto 20.00 g of activated carbon by an equal volume impregnation method, and the room temperature is sealed for 1 hour;

[0045] (3) The impregnated activated carbon first was dried in a vacuum oven (vacuum degree less than -0.09 MPa) at 50 ° C for 1 hour, and then dried in a vacuum oven (vacuum degree less than -0.09 MPa) for 4 hours, A1.

[0046] A1 at 180 ° C in reaction conditions, acetylene air speed 80h -1 At the end of the hydrochloride volume ratio of 1.2: 1, the acetylene conversion is 85.0%, and the reaction selectivity was 99.8%.

Embodiment 2

[0048] (1) 14.66 g of a copper boricrate (45% aqueous solution) was taken, and 7.00 g of deionized water was added to the impregnation fluid of copper-containing ion and tetrafluoroborate.

[0049] (2) Immerse the above impregnation liquid onto 20.00 g of activated carbon by an equal volume impregnation method, and the room temperature is sealed for 1 hour;

[0050] (3) The impregnated activated carbon first was dried in a vacuum oven at 50 ° C for 1 hour, followed by drying at a vacuum oven (vacuum degree less than -0.09 MPa) at a vacuum oven at a vacuum oven at a vacuum oven at a vacuum oven at a vacuum oven at a 90 ° C. Catalyst. A2.

[0051] A2 is 180 ° C in the reaction conditions, acetylene air is 40h -1 At a substantial ratio of hydrogen chloride ratio 1.2: 1, the acetylene conversion is 90.1%, and the reactive selectivity is 99.8%.

Embodiment 3

[0053] (1) 10.06 g of tetrahydrate trifluoroacetate is dissolved in 19.00 g of anhydrous ethanol to obtain a bronze ion and trifluoroacetate anion of the impregnation liquid;

[0054] (2) Immerse the above impregnation liquid onto 20.00 g of activated carbon by an equal volume impregnation method, and the room temperature is sealed for 1 hour;

[0055] (3) The impregnated activated carbon first was dried in a vacuum oven (vacuum degree less than -0.09 MPa) at 50 ° C for 1 hour, and then dried in a vacuum oven (vacuum degree less than -0.09 MPa) for 4 hours, A3.

[0056] A3 in the reaction conditions 180 ° C, acetylene air speed 60h -1 At a substantial ratio of hydrogen chloride ratio 1.2: 1, the acetylene conversion was 91.0%, and the reactive selectivity was 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com