Preparation method of all-vanadium redox battery electrode material

A battery electrode, vanadium oxidation technology, applied in battery electrodes, vanadium oxide, fuel cells and other directions, can solve the problems of poor electrochemical performance, restrict large-scale commercial application, etc., achieve good electrical conductivity, enhance electrochemical performance, good Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

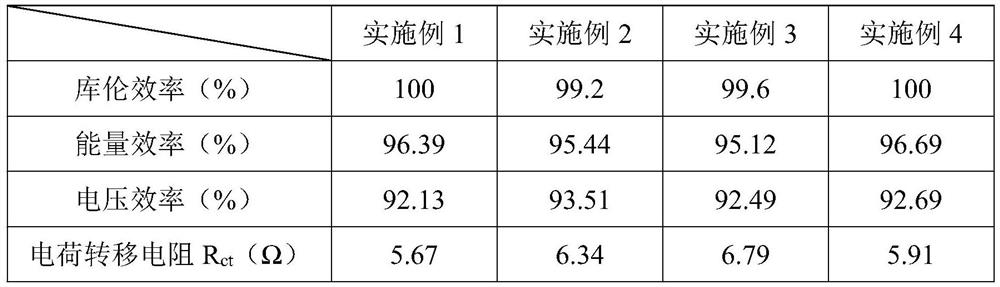

Embodiment 1

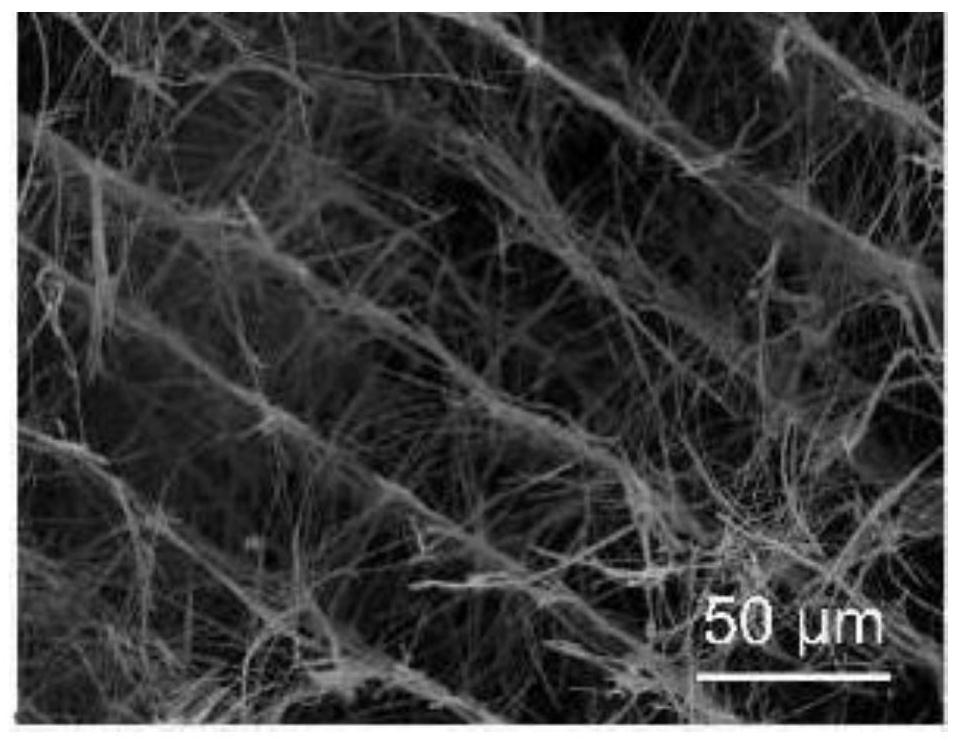

[0020] A preparation method of an all-vanadium redox battery electrode material, specifically comprising the following steps:

[0021] S1: Add polyacrylonitrile to N,N-dimethylformamide, ultrasonically dissolve, and then stir bismuth trioxide at room temperature for 1 hour, in which polyacrylonitrile, N,N-dimethylformamide and trioxide The mass volume ratio of bismuth is 4.4g:12mL:1.22g, then the mixed solution is moved into the electrospinning syringe pump, and the electrospinning is carried out under the conditions that the injection distance is 12cm, the injection rate is 3.6kV, and the injection voltage is 23kV. Filament, a polyacrylonitrile nanofiber film was obtained on a take-up roll.

[0022] S2: Add tetraethyl orthosilicate to absolute ethanol, wherein the volume ratio of tetraethyl orthosilicate and ethanol is 1.2:6, stir and dissolve at room temperature to obtain solution I; add phosphoric acid to deionized water , wherein the mass volume ratio of phosphoric acid a...

Embodiment 2

[0026] A preparation method of an all-vanadium redox battery electrode material, specifically comprising the following steps:

[0027] S1: Add polyacrylonitrile to N,N-dimethylformamide, ultrasonically dissolve, and then stir tungsten trioxide at room temperature for 2 hours, in which polyacrylonitrile, N,N-dimethylformamide and tungsten trioxide The mass volume ratio is 5.7g: 20mL: 2.39g, then the mixed solution is moved into the electrospinning syringe pump, and the electrospinning is carried out under the conditions that the injection distance is 16cm, the injection rate is 3.8kV, and the injection voltage is 26kV. A film of polyacrylonitrile nanofibers was obtained on a take-up roll.

[0028] S2: Add tetraethyl orthosilicate to absolute ethanol, wherein the volume ratio of tetraethyl orthosilicate and ethanol is 1.8:10, stir and dissolve at room temperature to obtain solution I; add phosphoric acid to deionized water , wherein the mass volume ratio of phosphoric acid and ...

Embodiment 3

[0032] A preparation method of an all-vanadium redox battery electrode material, specifically comprising the following steps:

[0033] S1: Add polyacrylonitrile to N,N-dimethylformamide, ultrasonically dissolve, and then stir cerium oxide at room temperature for 1.5h, in which polyacrylonitrile, N,N-dimethylformamide and cerium oxide The mass volume ratio is 4.8g: 15mL: 1.55g, then the mixed solution is moved into the electrospinning syringe pump, and the electrospinning is carried out under the conditions that the injection distance is 14cm, the injection rate is 3.7kV, and the injection voltage is 24kV. A film of polyacrylonitrile nanofibers was obtained on a take-up roll.

[0034] S2: Add tetraethyl orthosilicate to absolute ethanol, wherein the volume ratio of tetraethyl orthosilicate and ethanol is 1.5:8, stir and dissolve at room temperature to obtain solution I; add phosphoric acid to deionized water , wherein the mass volume ratio of phosphoric acid and deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge transfer resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com