Preparation method of high-purity superfine hafnium boride powder and hafnium boride powder

A technology of hafnium boride and powder, which is applied in the field of hafnium boride preparation, can solve the problems affecting the purity of grain boundaries and the uniform distribution of ceramic structures, and achieve the effects of lowering temperature, avoiding uneven structure and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of high-purity ultrafine hafnium boride powder, comprising the following steps:

[0036] S1: mixing hafnium oxide, a boron source and a carbon source as raw materials, drying and pressing into a block; the boron source is boric anhydride and / or boric acid;

[0037] S2: The block is subjected to primary heat treatment, hot water treatment, and secondary heat treatment in sequence to obtain high-purity ultrafine hafnium boride powder; The temperature is higher than the primary heat treatment temperature.

[0038] Here, "high-purity and ultra-fine" means that the purity of the hafnium boride powder reaches ≥99%, and the particle size reaches 0.1-2 μm.

[0039] The raw materials of the present invention include hafnium oxide (HfO 2 ), boron source and carbon source, wherein boron source is boron anhydride (B 2 o 3 ) and / or boric acid (H 3 BO 3 ), that is, the boron source is B 2 o 3 , or, the boron source is H 3 BO 3 , or, the boron source is ...

Embodiment 1

[0075] A method for preparing high-purity ultrafine hafnium boride powder, comprising the following steps:

[0076] (1) Hafnium oxide powder with a purity of 99.9% and an average particle size of 1 μm, boric anhydride with a purity of 99.9% and an average particle size of 1 μm, and carbon black with a purity of 99.8% are put into a polyethylene bottle according to a mass ratio of 56:28:16, Use ethanol and grinding balls to mix, the mixing time is 15h, the amount of ethanol added is 15ml / g of the total feeding amount, after mixing, dry and press into blocks;

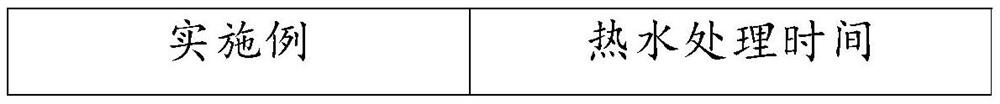

[0077] (2) Heat the block in a high-temperature furnace at 1300°C for 60 minutes once, place the block after heat treatment in hot water at 80°C for 30 minutes to remove boron oxide, heat it twice at 1600°C for 60 minutes, and finally crush it to obtain High-purity ultra-fine hafnium boride powder.

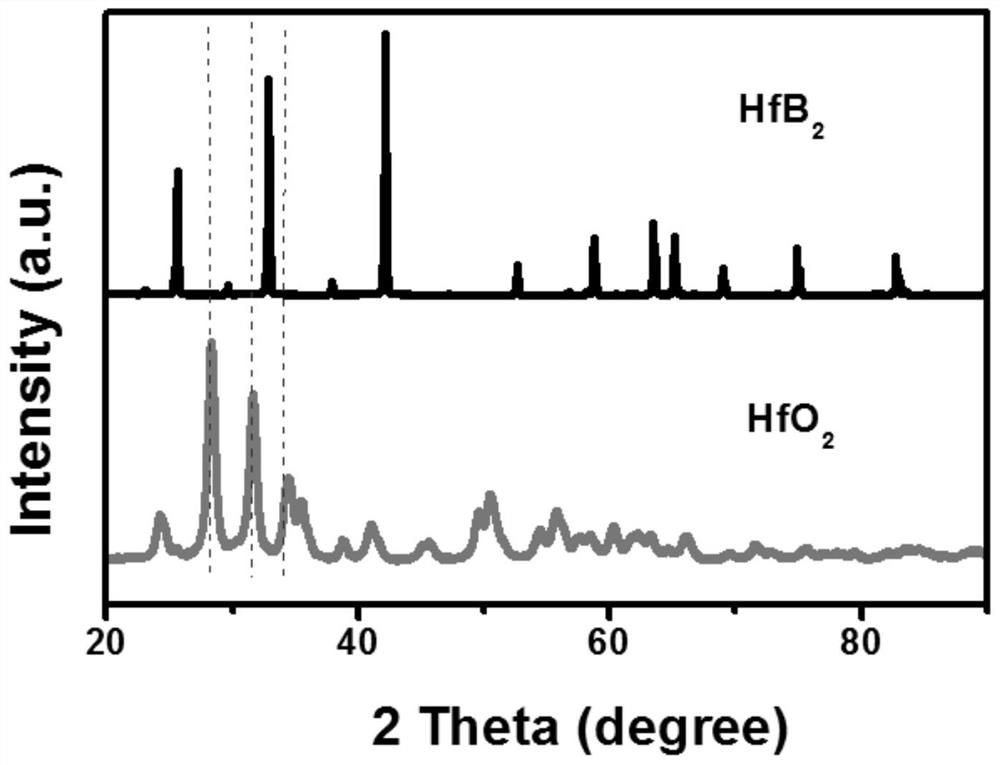

[0078] Gained product is carried out purity, particle size analysis and XRD characterization, specifically see table 1 and...

Embodiment 2

[0080] A method for preparing high-purity ultrafine hafnium boride powder, comprising the following steps:

[0081] (1) Put hafnium oxide powder with a purity of 99.5% and an average particle size of 1 μm, boric acid with a purity of 99.5% and an average particle size of 1 μm, and carbon black with a purity of 99.5% in a polyethylene bottle according to a mass ratio of 46:41:13, and use Mix ethanol and grinding balls, the mixing time is 18h, the amount of ethanol added is 20ml / g of the total feeding amount, after mixing, dry and press into blocks;

[0082] (2) Heat the block in a high-temperature furnace at 1150°C for 120 minutes once, place the heat-treated block in hot water at 60°C for 90 minutes to remove boron oxide, heat it twice at 1400°C for 180 minutes, and finally crush it to obtain High-purity ultra-fine hafnium boride powder.

[0083] The obtained product was analyzed for purity and particle size, see Table 1 for details, and the product purity reached 99.03wt%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com