Shear thickening fluid, coating, preparation methods of shear thickening fluid and coating and application of coating

A technology of thickening liquid and powder, which is applied in the field of protection and coating. It can solve the problems of self-agglomeration, the reduction of energy absorption effect of shear thickening liquid, and the influence of coating protection effect, etc., and achieve the increase of hydrogen bond interaction, Shear thickening is easy and the effect of reducing self-agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

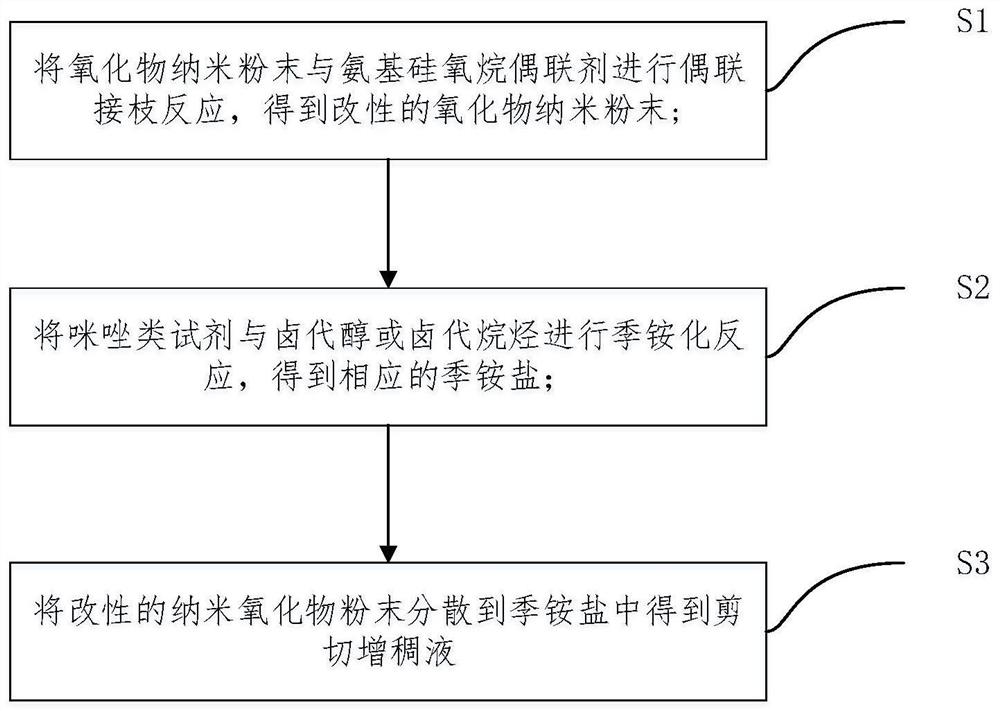

Method used

Image

Examples

Embodiment 1

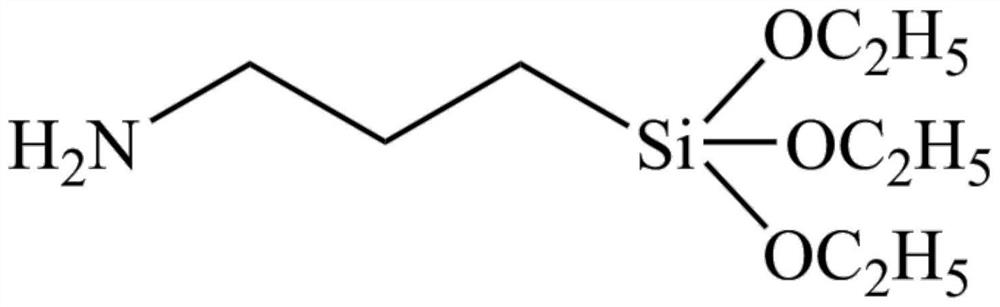

[0103] In Example 1, the oxide nanopowder is Nano-SiO 2 , the aminosiloxane coupling agent is γ-aminopropyltriethoxysilane, and the specific model is KH-550.

[0104] Concrete preparation steps are as follows:

[0105] In the first step, 2.5gNano-SiO 2 Under ultrasonic conditions (80Hz, 30min), disperse evenly in 62.5ml of H 2 O+CH 3 CH 2 OH mixed solution (water=15.625ml in this example; ethanol=46.875ml), the Nano-SiO after hydrolysis 2 ,

[0106] In the second step, weigh 0.625g of KH-550 and the hydrolyzed Nano-SiO 2 Mixing is carried out, and after mixing evenly, acetic acid is slowly added dropwise to adjust the pH value of the solution to be between 4 and 5, and then stirred in a constant temperature water bath at 75°C for 4 hours to obtain a mixture containing precipitates. During the stirring process in a constant temperature water bath, the mixture was condensed and refluxed at 80°C under a nitrogen atmosphere.

[0107] The 3rd step, the mixture that obtains ...

Embodiment 2

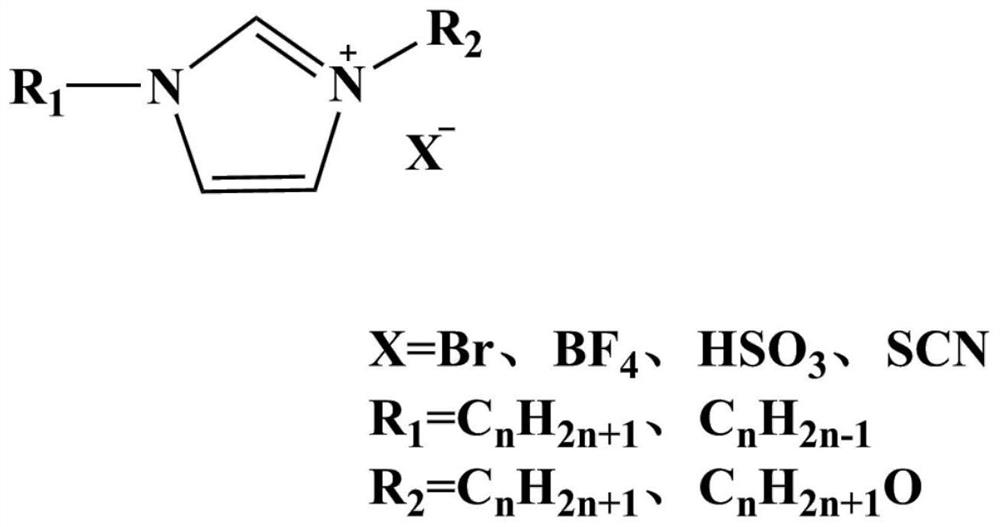

[0112] In Example 2, the halogenated alcohol is ethyl bromide, and the imidazole reagent is 1-vinylimidazole.

[0113] The preparation method is as follows:

[0114] Measure the 1-vinylimidazole of 0.94g and the ethyl acetate of 15ml respectively, join in the three-necked flask of 100ml, after mixing uniformly, add the bromoethane of 2.18g again, then the material in the three-necked flask is mixed uniformly, obtain mixture. Specifically, the process of mixing the materials in the three-necked flask was magnetically stirred in an oil bath at 85°C under a nitrogen atmosphere, and condensed and refluxed for 18 hours to obtain a liquid crude product.

[0115] After the reaction was completed, the liquid crude product was cooled at room temperature, and the solution was separated into layers, wherein the upper layer was an ethyl acetate layer, and the lower layer of light yellow viscous layer was a quaternary ammonium salt.

[0116] Extract the pale yellow viscous layer of the low...

Embodiment 3

[0119] In Example 3, the halogenated alcohol is bromoethanol, and the imidazole reagent is 1-vinylimidazole.

[0120] Mix 6.248g of bromoethanol and 15ml of acetonitrile as a solvent (15ml of acetonitrile is evenly divided into two parts, and mix with bromoethanol twice) and pour it into a three-necked flask, then magnetically stir the oil bath at 80°C for 30min to make the bromine Mix ethanol and acetonitrile evenly.

[0121] The 1-vinylimidazole of 4.703g is dissolved in 15ml acetonitrile, after dissolving is finished, in the three-necked flask, drip with constant pressure funnel, and pass into N 2 Magnetic stirring in an oil bath at 80°C, reflux for 24 hours. After the reaction is completed, pour the obtained liquid into a single-necked flask dedicated to rotary evaporation and perform rotary evaporation for 20 minutes under the parameters of temperature of 50°C, pressure of -0.08MPa, and rotation speed of 10r / min to obtain a liquid crude product, crude product It is slig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com