A high-strength anti-aging optical fiber outer layer coating and its preparation method

An aging-resistant, high-strength technology, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems affecting the overall performance of the outer optical fiber coating, inconvenient practical application, poor compatibility, etc., and achieve excellent mechanical properties And anti-aging performance, high practicality, good effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

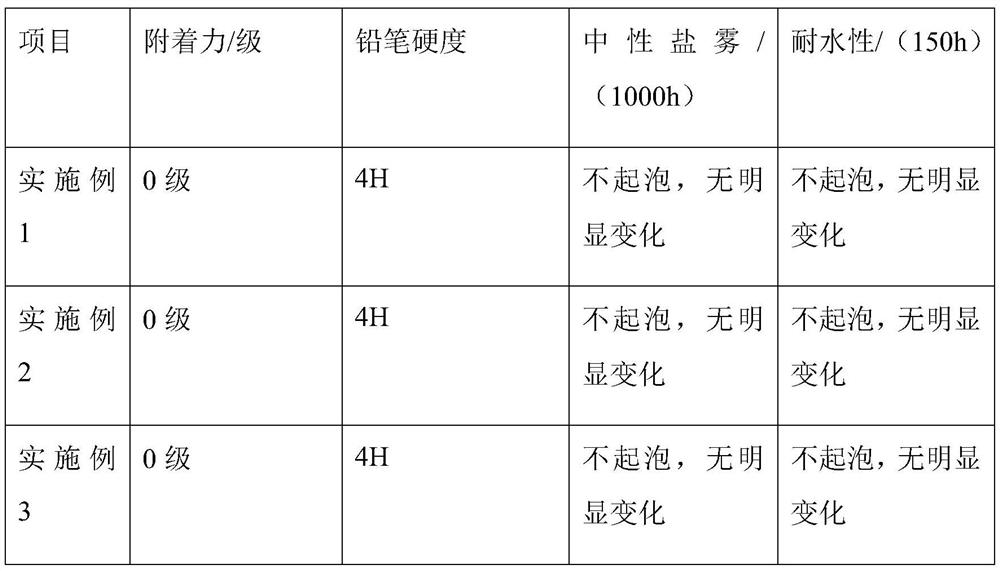

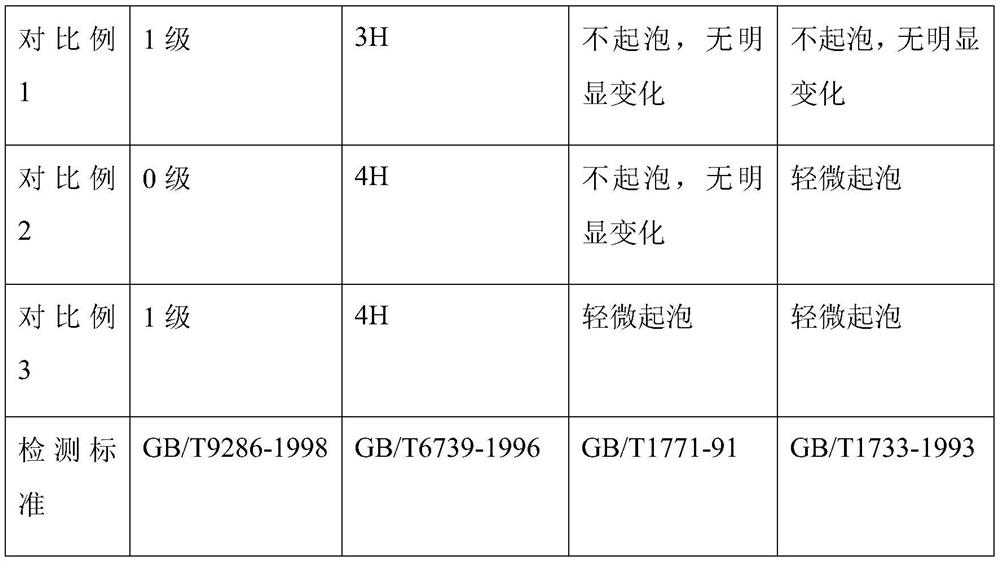

Examples

Embodiment 1

[0034] A preparation method of a high-strength aging-resistant optical fiber outer layer coating, comprising the following steps:

[0035] (1) Take paraformaldehyde and melamine, mix and stir for 20 minutes, and adjust the pH to 8.5 with triethylamine to obtain material A; wherein the molar ratio of melamine to formaldehyde is 1:7;

[0036] Take titanium dioxide and deionized water, add a dispersant, ultrasonically disperse for 30 minutes, add material A, heat up to 80°C, and react at a constant temperature for 1.5 hours, add hexafluorobutanol, adjust the pH to 5.5 with nitric acid, continue the reaction for 8 hours, and adjust the pH to 8 , cooled, collected by centrifugation, washed with deionized water, and dried in vacuum to obtain modified titanium dioxide;

[0037] (2) Take linseed oil and glycerin, mix well, heat up to 110°C, add alcoholysis catalyst, continue to heat up to 230°C, keep warm until the ethanol tolerance is qualified, then cool down, and add phthalic anhyd...

Embodiment 2

[0043] A preparation method of a high-strength aging-resistant optical fiber outer layer coating, comprising the following steps:

[0044] (1) Take paraformaldehyde and melamine, mix and stir for 25 minutes, and adjust the pH to 8.5 with triethylamine to obtain material A; wherein the molar ratio of melamine to formaldehyde is 1.1:7;

[0045] Take titanium dioxide and deionized water, add a dispersant, ultrasonically disperse for 32 minutes, add material A, heat up to 85°C, and react at a constant temperature for 1.3 hours, add hexafluorobutanol, adjust the pH to 5.5 with nitric acid, continue the reaction for 9 hours, and adjust the pH to 8.5 , cooled, collected by centrifugation, washed with deionized water, and dried in vacuum to obtain modified titanium dioxide;

[0046] (2) Take linseed oil and glycerin, mix well, heat up to 115°C, add alcoholysis catalyst, continue to heat up to 235°C, keep warm until the ethanol tolerance is qualified, then cool down, cool down to 175°C...

Embodiment 3

[0052] A preparation method of a high-strength aging-resistant optical fiber outer layer coating, comprising the following steps:

[0053] (1) Take paraformaldehyde and melamine, mix and stir for 20-30min, and adjust the pH to 8.5 with triethylamine to obtain material A; wherein the molar ratio of melamine to formaldehyde is 1.2:7;

[0054] Take titanium dioxide and deionized water, add dispersant, ultrasonically disperse for 30-35min, add material A, heat up to 90°C, react at constant temperature for 1h, add hexafluorobutanol, adjust pH to 5.5 with nitric acid, continue to react for 10h, adjust pH to 9. Cool, collect by centrifugation, wash with deionized water, and dry in vacuum to obtain modified titanium dioxide;

[0055] (2) Take linseed oil and glycerin, mix well, heat up to 120°C, add alcoholysis catalyst, continue to heat up to 230°C, keep warm until the ethanol tolerance is qualified, then cool down, and add phthalic anhydride after cooling down to 180°C , xylene, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com