Method for continuously producing cellulase and co-producing ethanol under control of inducer

A cellulase and inducer technology is applied in the field of inducer-controlled continuous cellulase production and ethanol production, and can solve the problems of large demand for cellulase and high cost of cellulase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] (1) Preparation of cellulase promoter and ethanol and co-production with ethanol

[0037] Cornstarch, water, and concentrated hydrochloric acid were mixed in a ratio of 20:100:0.(5v / v / v), treated at 140°C for 30 minutes under stirring conditions, and adjusted to pH 4.0-6.0 with 20% NaOH after the treatment;

[0038]Add 0.5% (v / v) corn steep liquor to it, sterilize at 120°C for 20 minutes, after the temperature drops to 30°C, add 0.1% (w / v) Saccharomyces cerevisiae, anaerobically ferment at 30°C, and wait for the fermentation liquid glucose When the concentration drops to 1-2% (w / v), the fermentation is stopped, and the ethanol in the fermentation broth is distilled to obtain the sugar liquid and ethanol that remove ethanol after distillation, and this sugar liquid is the subsequent production of cellulase accelerator. The combination of the process and the subsequent cellulase fermentation process realizes the co-production process of cellulase and ethanol;

[0039] (2...

Embodiment 1

[0066] The present embodiment provides a kind of preparation method of cellulase accelerator:

[0067] Add 3kg of cornstarch and 10L of water to a 20L Hastelloy reactor, mix well, add 63mL of concentrated hydrochloric acid, stir well, raise the temperature to 135°C, keep it warm for 60min, after cooling down, take out 7L of the reaction solution into a 10L stainless steel fermenter, add 35mL Corn steep liquor, sterilized at 118°C for 20 minutes, after sterilization, pour in cooling water, after the temperature drops to 30°C, add 21g of Saccharomyces cerevisiae into the tank, stir at 120r / min, ferment for 48h, measure the concentration of glucose in the fermentation liquid 1.0g / 100mL, stop fermentation. Transfer the fermented liquid into a distillation flask, and carry out vacuum distillation at 40°C. After all ethanol is distilled, the remaining yeast fermented sugar liquid is the cellulase-producing accelerator.

[0068] During the enzyme production process, the cellulase pr...

Embodiment 2

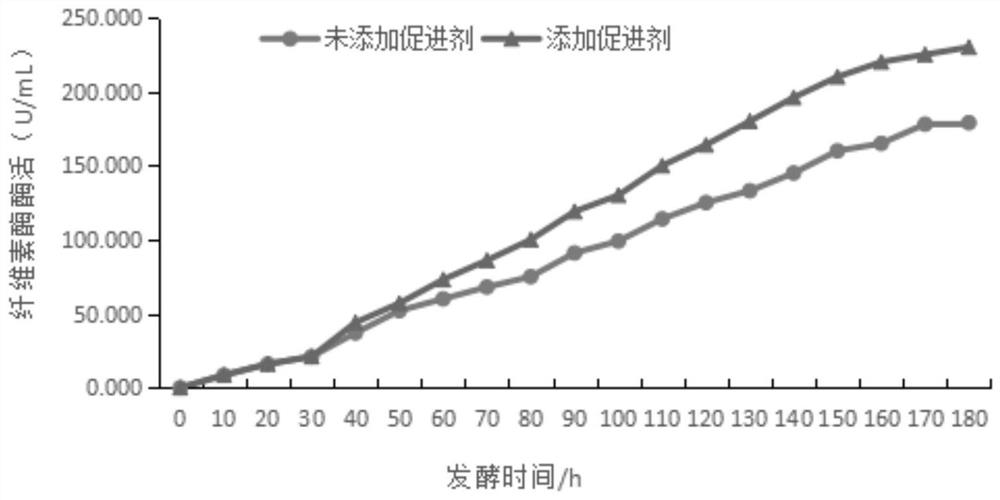

[0070] This embodiment provides a method for fermenting cellulase by feeding a cellulase production promoter.

[0071] (1) Select two 10L stainless steel fermentation tanks for cellulase fermentation, one of which is used as a control group, and no enzyme promoter is added during the fermentation process, and the other tank is the experimental group, which is fed with a cellulase promoter during the fermentation process

[0072] (1) Preparation of cellulase-producing fermentation medium: glucose 10g / L, cellulose powder 20g / L, peptone 10g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 0.2g / L, pH6.5, in 10L Sterilize at 121°C for 20 minutes in a fermenter.

[0073] (2) Access the Trichoderma reesei seed solution whose sedimentation rate has reached 90%, 10% inoculum size, 30°C of temperature (automatic control), pH5.5-6.0 (adding automatic control with 20% sodium carbonate solution flow), stirring speed 300r / min, air flow 7.5L / min, tank pressure 0.03MPa.

[0074] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com