Straw-based amphoteric dye adsorbent as well as preparation method and application thereof

An adsorbent and straw technology, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problems of inability to decolorize dyes, single function of adsorbents, etc., and achieve good environmental friendliness and adsorption time. Short, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

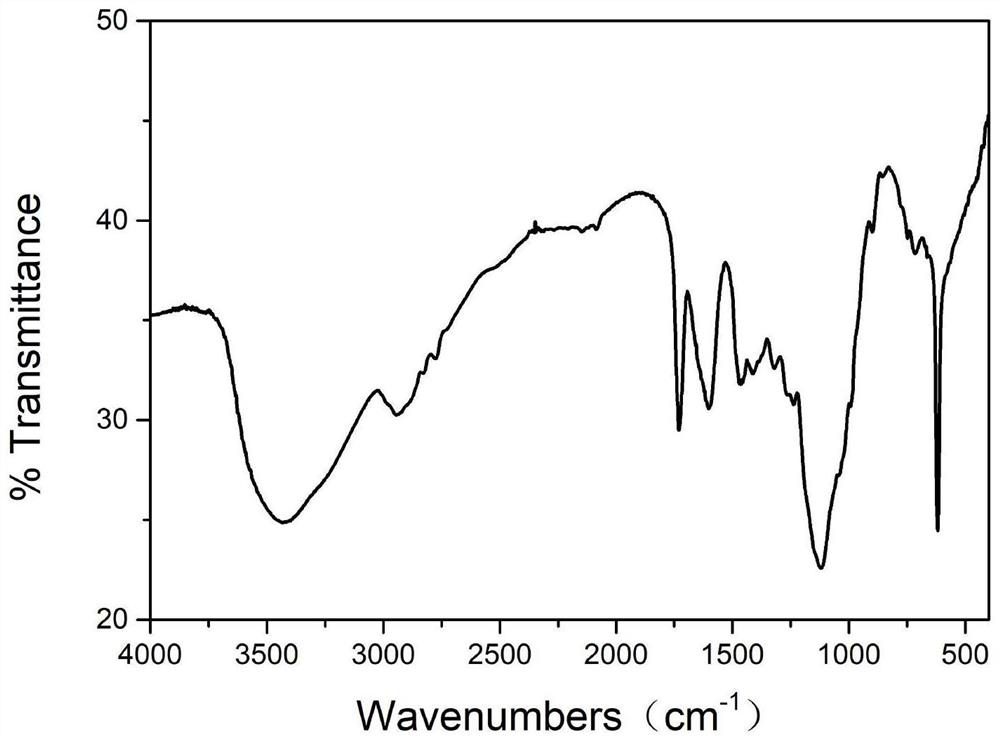

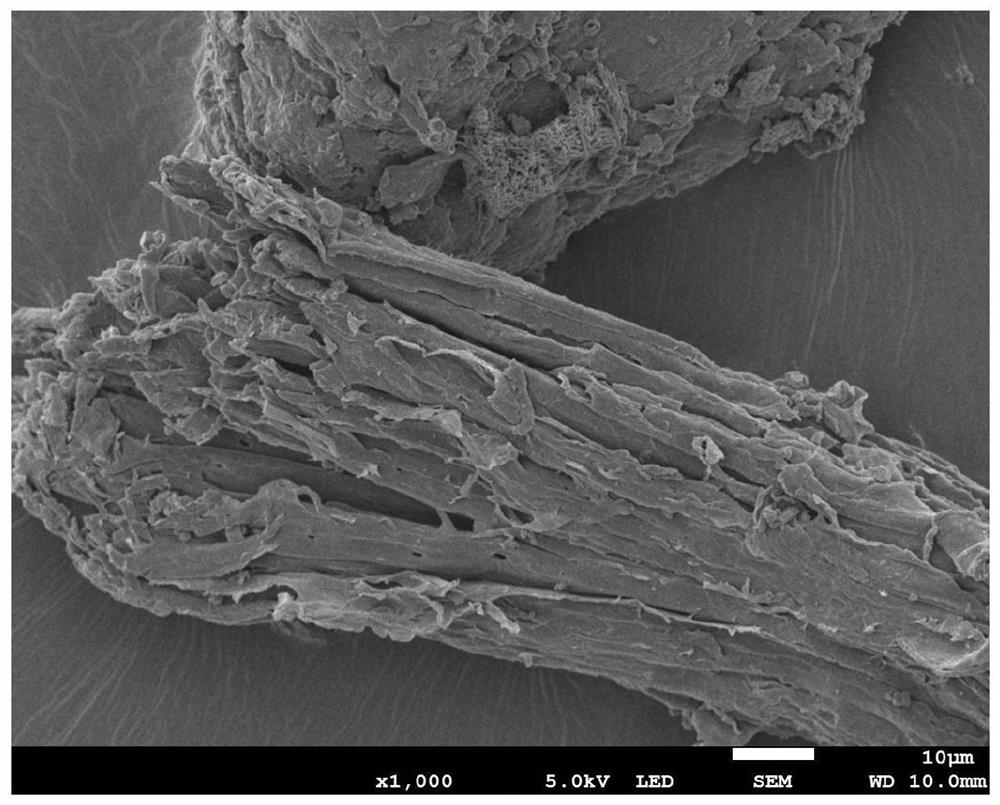

[0050] Such as Figure 1-2 As shown, a straw-based amphoteric dye adsorbent uses straw as a polymer skeleton, and through graft substitution and graft copolymerization, carboxyl and tertiary amino groups are grafted on the cellulose molecular chain of straw to form both There are anionic and cationic straw-based amphoteric dye sorbents.

[0051] The surface of the straw-based amphoteric dye adsorbent has a pore structure, and a large number of anion and cationic groups are distributed on the straw cellulose molecular chain.

[0052] The adsorption principle of the amphoteric dye adsorbent is:

[0053] The pore structure of the straw-based amphoteric dye adsorbent plays a role of physical adsorption in the adsorption process; at the same time, the carboxyl group in the adsorbent can be deprotonated and converted into carboxylate anion under weak alkaline conditions, which has good electrostatic properties for cationic dyes. Attraction, ion exchange and other chemical adsorpti...

Embodiment 2

[0094] After peeling the corn stalks, wash them three times with deionized water, dry them in an oven at 60°C, and then pulverize them to obtain straw powder, then put the straw powder in a three-necked bottle, and add 2% H 2 o 2 aqueous solution, and use 20% NaOH aqueous solution to adjust the pH of the system to 12.5, control the reaction temperature to 60°C, react for 5 hours under stirring conditions, filter and wash the residue with deionized water to obtain pretreated corn stover cellulose. Take 0.3g of corn stalk cellulose, add 6mL of ethanol aqueous solution with a volume fraction of 85%, add 0.18g of powdered NaOH solid in two times according to the ratio of mass ratio of 3:1, after adding alkali for the first time, stir well and put Put it into a constant temperature water bath at 30°C for alkalization. After reacting for 60 minutes, 0.36 g of chloroacetic acid was dissolved in 10 mL of 85% ethanol aqueous solution, and then added dropwise while stirring, and the et...

Embodiment 3

[0096] After peeling the corn stalks, wash them three times with deionized water, dry them in an oven at 60°C, and then pulverize them to obtain straw powder, then put the straw powder in a three-necked bottle, and add 2% H 2 o 2 aqueous solution, and use 20% NaOH aqueous solution to adjust the pH of the system to 12.5, control the reaction temperature to 60°C, react for 5 hours under stirring conditions, filter and wash the residue with deionized water to obtain pretreated corn stover cellulose. Take 0.3g of corn stalk cellulose, add 6mL of ethanol aqueous solution with a volume fraction of 85%, add 0.18g of powdered NaOH solid in two times according to the ratio of mass ratio of 3:1, after adding alkali for the first time, stir well and put Put it into a constant temperature water bath at 30°C for alkalization. After reacting for 60 minutes, 0.36 g of chloroacetic acid was dissolved in 10 mL of 85% ethanol aqueous solution, and then added dropwise while stirring, and the et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com