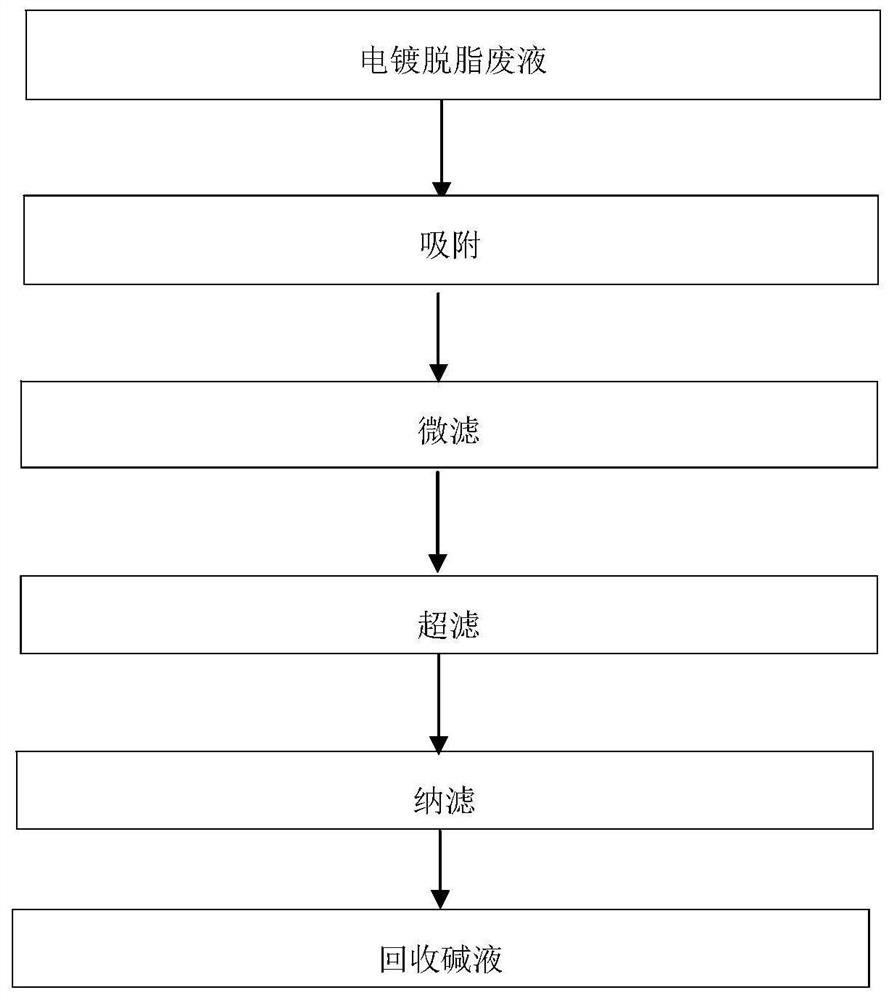

Method for recovering alkali from electroplating degreasing waste liquid

A waste liquid and hollow technology, which is applied to chemical instruments and methods, alkali metal compounds, metallurgical wastewater treatment, etc., can solve the problems of complex equipment, blockage, cumbersome operation, etc., and achieve low concentration, simple operation, and high alkali recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The electroplated degreasing waste liquid 1000L, wherein the sodium hydroxide concentration is 1 mol / L, oil concentration 329 ppm, COD4500 ppm, metal ion concentration: Al 156 ppm, Fe 101PPM, Cu 44 ppm, Zn 230 ppm. 3 kg of activated carbon was added to the waste liquid, and after 30min at normal temperature, the carbon mixture was obtained.

[0045] The resulting microfiltration device is introduced into the ultrafiltration device by 10 micrometer aperture, the ultrafiltration membrane is introduced into a PP material, and the molecular weight 50000 is intercepted, and the ultrafiltration is completed under normal temperature and 0.1 MPa pressure, the ultrafiltration is 90%. .

[0046]The recovered ultrafiltration was introduced into the nanofiltration device, and the nanofiltration membrane used was a sulfonated polyether sulfone material, and the elongated molecular weight was 720 Daltons, nanofiltration pressure 0.5 MPa, obtained by nanofiltration, nanofiltration recov...

Embodiment 2

[0050] Based on the embodiment, the nanofiltration membrane is exchanged to the alkali-resistant filming of 200 Daltons, and the nanofiltration pressure is 0.8 MPa, and other conditions are identical to Example 1.

[0051] The sodium hydroxide concentration of sodium hydroxide was 1 mol / L, no oil, COD of 531 ppm, metal ions, COD, and COD, and 4.51 ppm, Cu 0.23 ppm, Zn 4.5 ppm, to reagent, alkali solution. The total recovery rate of the resulting alkali is 75%,

Embodiment 3

[0053] Based on the embodiment, the ultrafiltration membrane is exchanged to a film having a molecular weight of 10,000 Daltons, ultrafiltration pressure 0.3 MPa, and other conditions are identical to Example 1.

[0054] In the obtained nanofiltration, sodium hydroxide concentration of 1 mol / L, oil containing 0.4 ppm, COD is 655 ppm, metal ions Al9.7 ppm, Fe 1.1 ppm, Cu 1.5 ppm, Zn 8.7 ppm, to reagent, alkali solution. The total recovery rate of the obtained alkali solution was 74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com