Preparation method and application of composite metal oxide surface modified lithium metal battery negative electrode current collector

A lithium metal negative electrode and lithium metal battery technology, which is applied in the direction of battery electrodes, active material electrodes, electrode carriers/collectors, etc., can solve the problems of poor safety performance, poor cycle performance, and low Coulombic efficiency, and achieve easy operation, The effect of improving discharge specific capacity and cycle performance and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

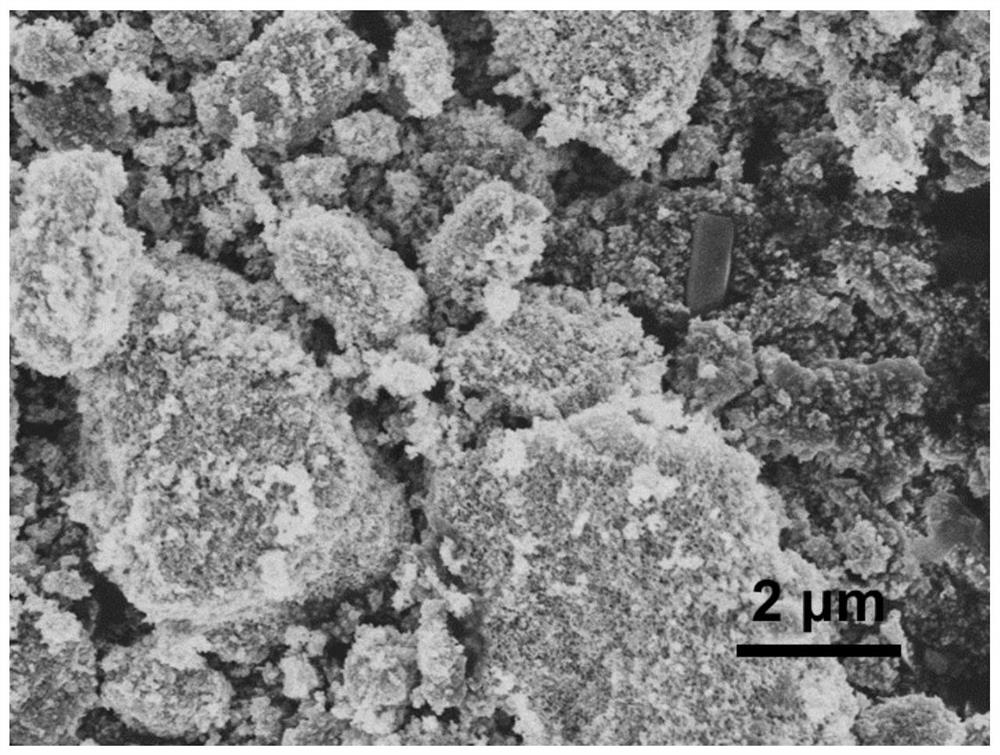

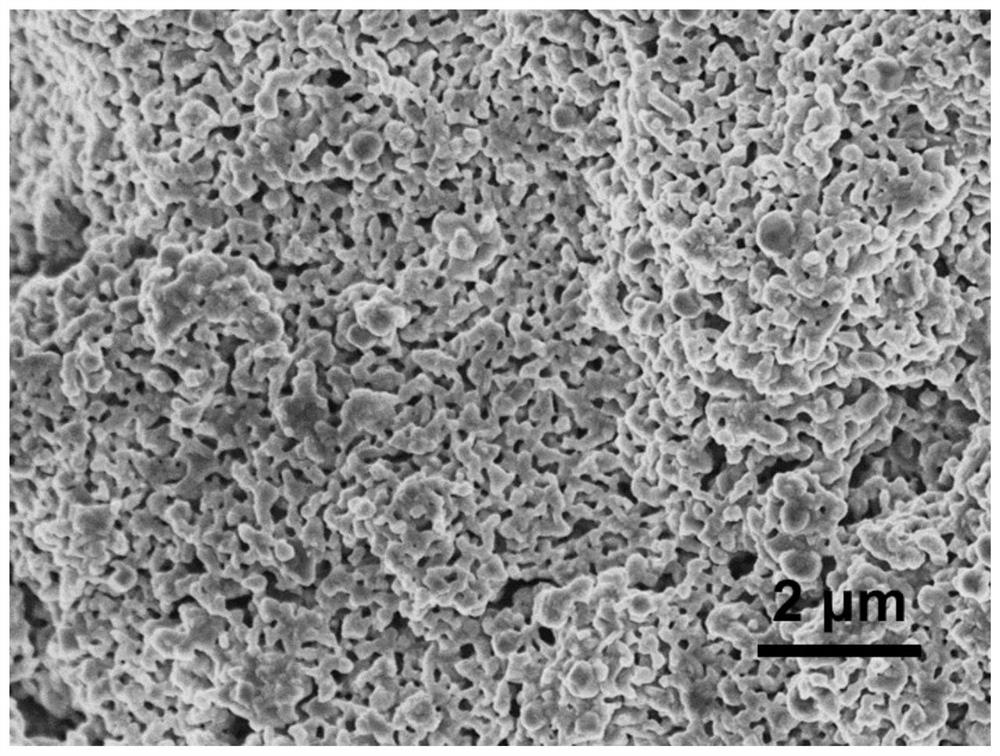

[0029] Weigh 1.0g (La 0.6 Sr 0.4 ) 0.9 co 0.2 Fe 0.8 o 3+δ Disperse the particles into 5.0g organic solvent N-methylpyrrolidone, stir at room temperature for 6h (300r / min) to obtain a uniform slurry, and then evenly coat it on copper foil, dry it at 60°C for 12h, and then dry it under argon Calcining at 600° C. for 6 hours under a protective atmosphere can obtain the lithium metal battery negative electrode current collector with a composite metal oxide surface modified according to the present invention. by (La 0.6 Sr 0.4 ) 0.9 co 0.2 Fe 0.8 o 3+δ After surface modification, under the protection of dry argon gas, a 20 μm lithium sheet with the same shape and size was attached to the surface of the negative electrode current collector, and kept at 200°C for 1 hour to obtain a negative electrode current collector filled with lithium.

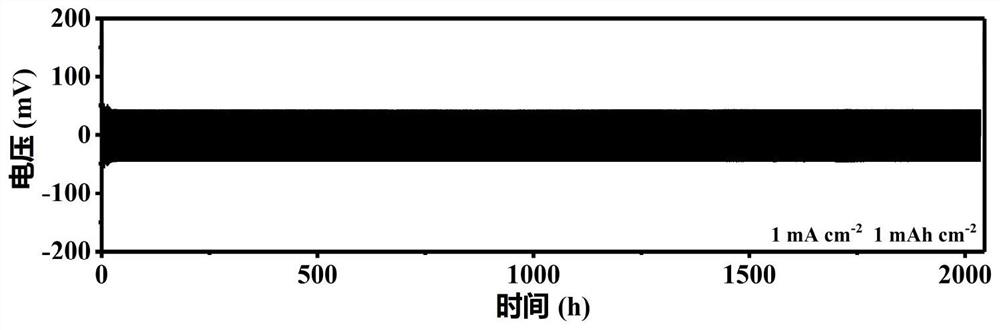

[0030] The scripture (La 0.6 Sr 0.4 ) 0.9 co 0.2 Fe 0.8 o 3+δ The surface-modified lithium metal battery negative current colle...

Embodiment 2

[0032] Weigh 5.0g La 0.6 Sr 0.4 NiO 3 Disperse the particles into 25.0g of organic solvent isopropanol, stir at room temperature for 12h (200r / min) to obtain a uniform slurry, and then evenly coat it on copper foil, dry it at 80°C for 4h, and place it in an argon protective atmosphere Calcined at 900°C for 4 hours to obtain the La 0.6 Sr 0.4 NiO 3 Surface-modified lithium metal battery anode current collector.

[0033] La 0.6 Sr 0.4 NiO 3 The negative electrode current collector of the surface modified lithium metal battery is assembled with lithium metal to form a Li|Cu battery. The diaphragm of the Li|Cu symmetrical battery is a PE diaphragm, and the electrolyte is 1mol / L bistrifluoromethanesulfonylimide lithium dissolved in a volume ratio of 1 : 1 of 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME), and add 1wt% LiNO 3 mixed solution. At a current density of 1mA / cm 2 , The deposition capacity is 1mAh / cm 2 Tested under the conditions, the coulombic effici...

Embodiment 3

[0035] Weigh 3.0g La 0.8 Sr 0.2 CrO 3 Disperse the particles into 10.0g organic solvent dimethyl sulfoxide, stir at room temperature for 8h (240r / min) to obtain a uniform slurry, and then evenly coat it on a copper foil, dry it at 60°C for 12h, and then dry it under argon Calcined at 600°C for 6 hours under a protective atmosphere to obtain the La 0.8 Sr 0.2 CrO 3 Surface-modified lithium metal battery anode current collector. via La 0.8 Sr 0.2 CrO 3 After surface modification, under the protection of dry argon gas, a 50 μm lithium sheet with the same shape and size was attached to the surface of the negative electrode current collector, and kept at 230° C. for 3 hours to obtain a negative electrode current collector filled with lithium.

[0036] La 0.8 Sr 0.2 CrO 3 The negative electrode current collector of the surface modified lithium metal battery is matched with the lithium iron phosphate positive electrode material to form a full battery. The separator of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com