Renewable chromatographic system and method for removing nisin pigment and peculiar smell

A nisin and chromatographic system technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of nisin loss of activity, loss of its own activity, low activity recovery rate, etc. Achieve the effect of shortening the separation process and preparation cycle, high separation efficiency and recovery rate, fast and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

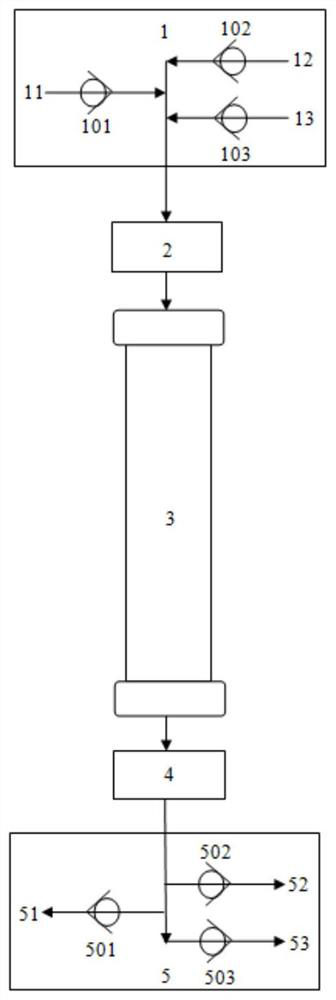

[0042] This embodiment provides a renewable chromatographic system for removing lactic acid chain bacteria pigment and odor, such as figure 1 As shown, the liquid system 1, the high pressure infusion pump, the mixer (not shown), the filter protection column 2, the column 3, the detector 4, the liquid system 5, wherein the liquid system 1 includes injection. Tube 11, inlet valve 101, balance liquid tube 12, balance liquid valve 102, regenerative liquid tube 13 and regenerative roll valve 103, the liquid system 5 includes a sample tube 51, a sample valve 501, a balanced liquid tube 52, a balance liquid Valve 502, regenerated liquid tube 53 and regenerative roll valve 503; medium of the column use a phenyl bonding silica gel (particle diameter 5 μm, aperture 120 angstrina), the chromatographic column size is: a diameter of 100 mm × length 1000 mm.

[0043] The medium packing of the column of the column of this example is produced by Ningbo Bocrupture Biotechnology Co., Ltd.

Embodiment 2

[0045] This embodiment provides a method of removing lactic acid chain bacteria pigment and odor, using the chromatographic system of Example 1 to separate the lactic acid Socolioma blended liquid, including the steps of:

[0046] Forward treatment: First adjust the pH of the lactic acid Socolioplasm to 3.5, then centrifuged, discard the precipitate, and take the supernatant.

[0047] Injective: Automatically open the balanced liquid tube valve in the inlet system in the liquid system, and the flow rate of 300 ml / min is injected;

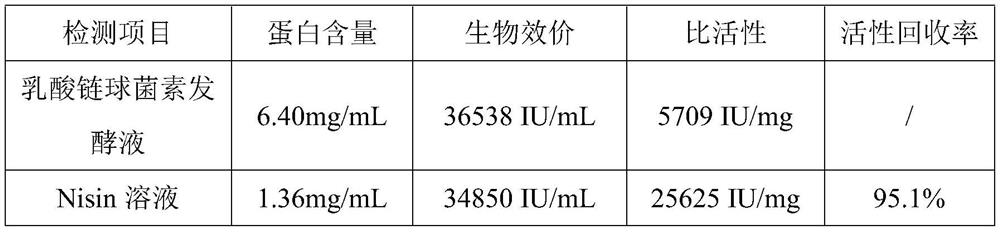

[0048] Collection: Set the UV detector wavelength of 220 nm, when the detector is displayed to rise, the liquid system automatically turns off the balanced liquid valve, and the sample valve in the outlet system opens, collecting Nisin samples from the sample tube, After the injection, close the injective valve, the in-liquid system automatically opens the balanced valve, eluted with sodium acetate-acetic acid buffer having a concentration of 50 mmol ...

Embodiment 3

[0055] This embodiment provides a method of removing lactic acid chain bacteria pigment and odor, using the chromatographic system of Example 1 to separate the lactic acid Socolioma blended liquid, including the steps of:

[0056] Forward treatment: First adjust the pH of the lactic acid Socolioplasm to 3.5, then centrifuged, discard the precipitate, and take the supernatant.

[0057] Injective: Automatically open the balanced liquid pipe valve in the inlet system in the in-liquid system, and the flow rate of 200 ml / min is sampled;

[0058] Collection: Set the UV detector wavelength of 220 nm, when the detector is displayed to rise, the liquid system automatically turns off the balanced liquid valve, and the sample valve in the outlet system opens, collecting Nisin samples from the sample tube, After the injection, close the injective valve, the in-liquid system automatically opens the balanced valve, eluted with sodium acetate-acetic acid buffer having a concentration of 50 mmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com