Hydrogen and metal product accompanying production method and system

A technology of metal products and production methods, applied in the field of metallurgy, can solve the problems of high prices, difficult to effectively manage green products and traditional products, etc., achieve high environmental protection level, and realize the effect of high-efficiency utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

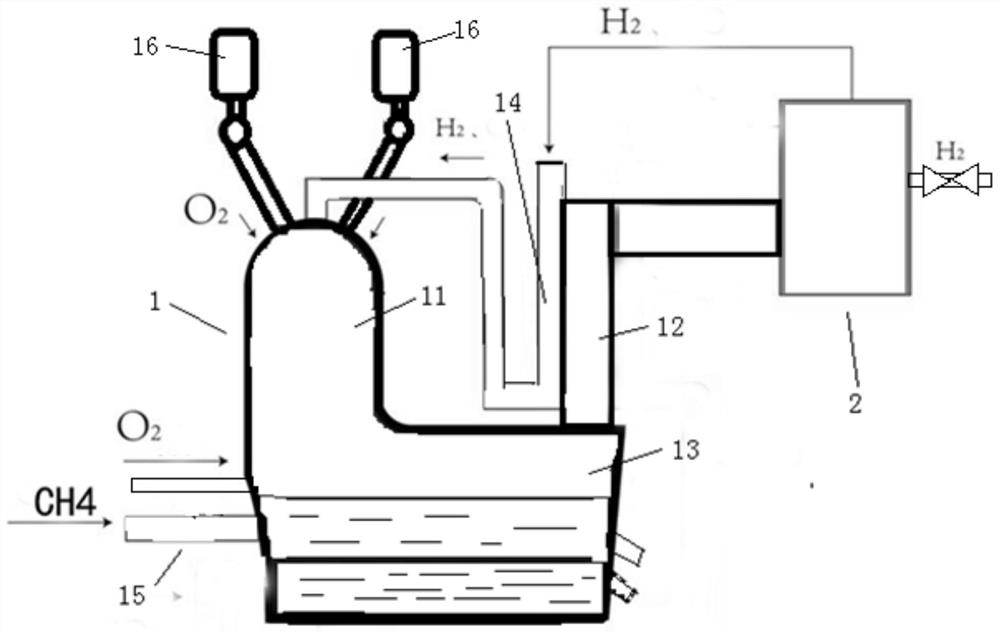

Embodiment 1

[0045] A method for producing hydrogen and metal products together, comprising the steps of:

[0046] S1. From the top of the smelting space of the flash metallurgical equipment, dry metal oxide ore powder and oxygen are added to the smelting space above 1300°C filled with high-temperature hydrogen. The ore powder particles are in full contact with hydrogen, and the reduction reaction occurs quickly. The solid-liquid product enters the melting pool of the flash metallurgy equipment, and the flue gas enters the upper channel of the melting pool and flows toward the ascending flue;

[0047] S2. Methane is injected into the molten pool at a temperature of 1450°C-1550°C, and the methane is cracked into carbon black and hydrogen; at the same time, oxygen is injected into the molten pool, and the excess H produced by oxygen and cracking 2 Combustion, supplementing heat for the molten pool, the excess hydrogen floats into the flue gas and flows in the direction of the ascending flue;...

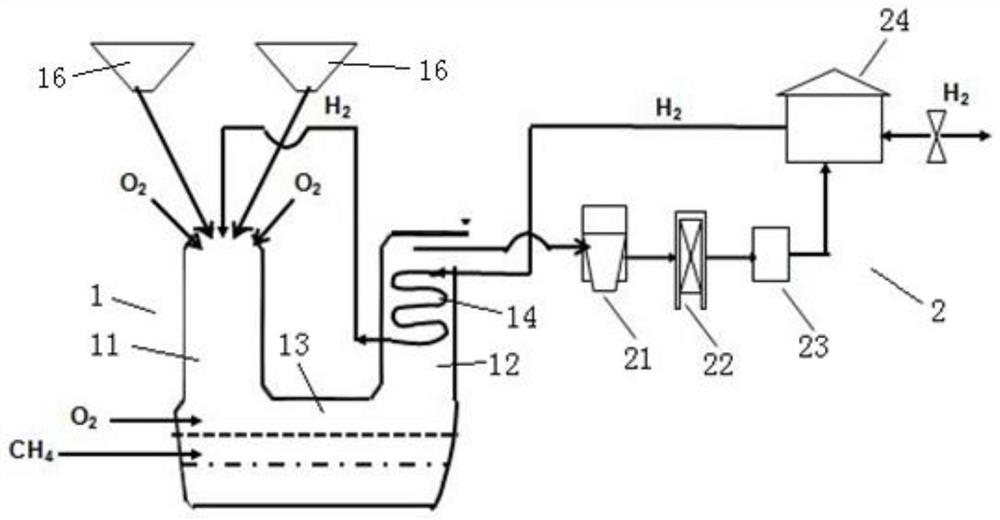

Embodiment 2

[0053] like figure 2 As shown, on the basis of Embodiment 1, the flue gas purification system 2 in this embodiment includes a dust removal device 21, a fan 22, a dehydration and decarbonization device 23, and a hydrogen cabinet 24 connected in sequence through pipelines. The inlet port of the dust removal device 21 is connected to the The outlet end of the heat exchange flue 12 is connected, and the hydrogen gas outlet end of the hydrogen tank 24 is connected with the inlet end of the cold medium flow channel 14 .

[0054] The working process of the production system accompanied by hydrogen and metal products described in the present embodiment is as follows:

[0055] S1. From the top of the smelting space 11 of the flash furnace 1, dry iron ore powder and oxygen are added to the smelting space 11 at 1300°C-1650°C filled with high-temperature hydrogen. The ore powder particles are fully in contact with the hydrogen gas, and the reduction reaction occurs quickly, and the ore p...

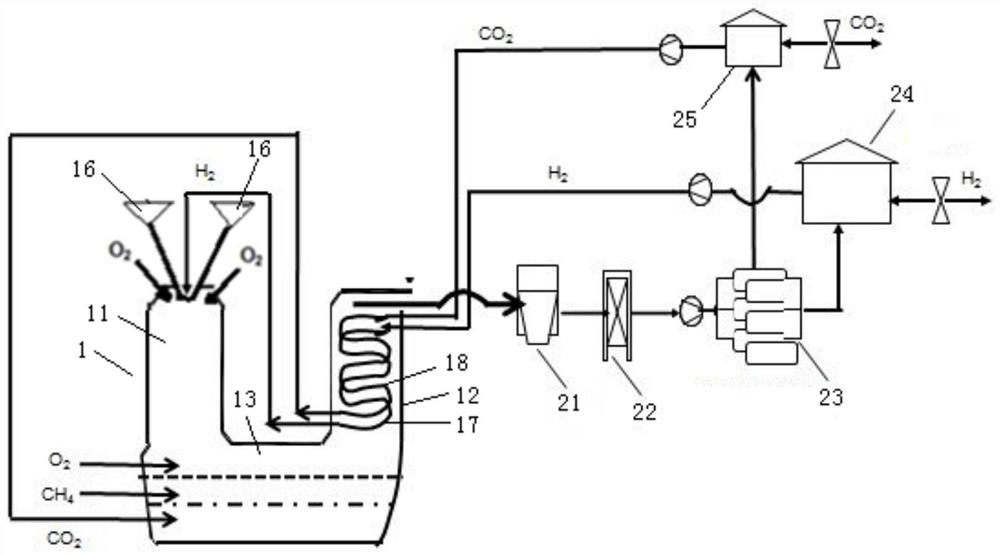

Embodiment 3

[0060] like image 3 As shown, on the basis of Embodiment 1, the difference from Embodiment 1 is that two kinds of cold medium passages are arranged in the heat exchange flue 12, which are cold medium passage one 17 and cold medium passage two 18 , the two cold medium channels are not connected to each other; the cold medium in the cold medium channel one 17 is high-concentration hydrogen returned after flue gas treatment, and the cold medium channel one 17 passes the high-concentration hydrogen through heat exchange and heating The pipeline is sent into the smelting space 11; the cold medium in the cold medium flow channel 2 18 is high concentration CO returned after decarburization 2 Gas, cold medium channel two will be high concentration CO 2 After the gas is heated up, it is sent into the molten metal layer through the pipeline.

[0061] In this embodiment, the flue gas purification system 2 includes a dust removal device 21, a fan 22, a dehydration and decarbonization d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com