3D printed bone defect repair scaffold loaded with endothelial extracellular matrix and preparation method of 3D printed bone defect repair scaffold

A technology of endothelial cells and 3D printing, which is applied in prosthetics, tissue regeneration, additive processing, etc., can solve problems such as short half-life, and achieve the effects of simple operation, increased number of branches, and high biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of a 3D printed bone defect repair scaffold loaded with endothelial extracellular matrix:

[0043] S1. Gelatin, sodium alginate and 58S bioglass were dissolved in distilled water to obtain a solution, wherein the mass / volume concentration of each component in the solution was gelatin 15%, sodium alginate 6%, and 58S bioglass 10.5%.

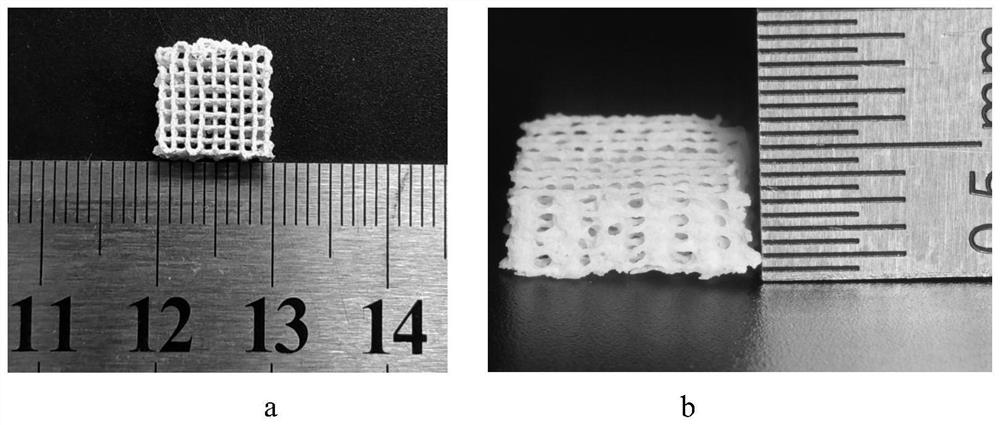

[0044] S2. The solution is stirred evenly by means of magnetic stirring and mechanical stirring to obtain 3D printing slurry, inject the 3D printing slurry into the 3D printing barrel, and start 3D printing after defoaming and homogenization. 3D printing uses a needle with an aperture of 0.41mm. Under the conditions of 0.38Mpa air pressure and 28°C, print at a printing speed of 10mm / s.

[0045] S3. The semi-finished stent is obtained after printing. The semi-finished stent is first physically cross-linked with a calcium chloride solution, and then chemically cross-linked by soaking in a glutaraldehyde solution; finally cleaned a...

Embodiment 2

[0050] Preparation of a 3D printed bone defect repair scaffold loaded with endothelial extracellular matrix:

[0051] S1. Gelatin, sodium alginate and 58S bioglass were dissolved in distilled water to obtain a solution, wherein the mass / volume concentration of each component in the solution was gelatin 15%, sodium alginate 6%, and 58S bioglass 10.5%.

[0052] S2. The solution is stirred evenly by means of magnetic stirring and mechanical stirring to obtain 3D printing slurry, inject the 3D printing slurry into the 3D printing barrel, and start 3D printing after defoaming and homogenization. 3D printing uses a needle with an aperture of 0.43mm. Under the conditions of 0.40Mpa air pressure and 27°C, print at a printing speed of 10mm / s.

[0053] S3. The semi-finished stent is obtained after printing. The semi-finished stent is first physically cross-linked with a calcium chloride solution, and then chemically cross-linked by soaking in a glutaraldehyde solution; finally cleaned a...

Embodiment 3

[0058] Preparation of a 3D printed bone defect repair scaffold loaded with endothelial extracellular matrix:

[0059] S1. Gelatin, sodium alginate and 58S bioglass were dissolved in distilled water to obtain a solution, wherein the mass / volume concentration of each component in the solution was gelatin 15%, sodium alginate 6%, and 58S bioglass 10.5%.

[0060] S2. Stir the solution evenly by magnetic stirring and mechanical stirring to obtain a 3D printing slurry, and prepare a bracket by 3D printing; in the 3D printing operation, inject the 3D printing slurry into the 3D printing barrel, start printing after defoaming and homogenization, Using a needle with an aperture of 0.40mm, print at a printing speed of 10mm / s under the conditions of 0.35Mpa air pressure and 29°C.

[0061] S3. The semi-finished stent is obtained after printing. The semi-finished stent is first physically cross-linked with a calcium chloride solution, and then chemically cross-linked by soaking in a glutar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com