Process and device for producing ammonium sulfite and byproduct thiosulfate mixed nutrient solution

A technology for by-producing thiosulfate and ammonium sulfite is applied in the preparation of alkali metal sulfites, thiosulfate/dithionite/polythionite, combined devices, etc., and can solve complex processes. , high cost of thiosulfate fertilizer, sulfur easily produces sublimated sulfur and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

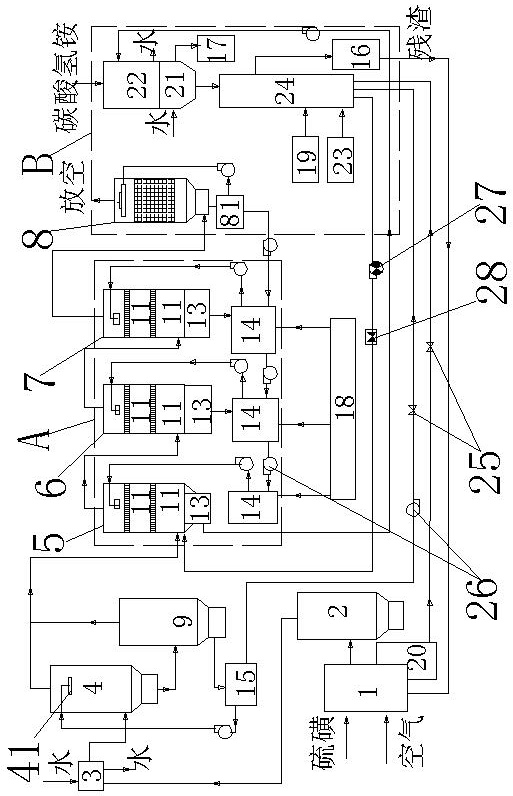

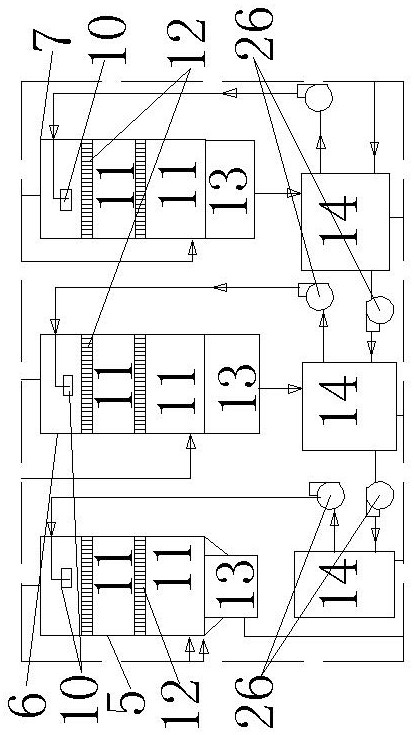

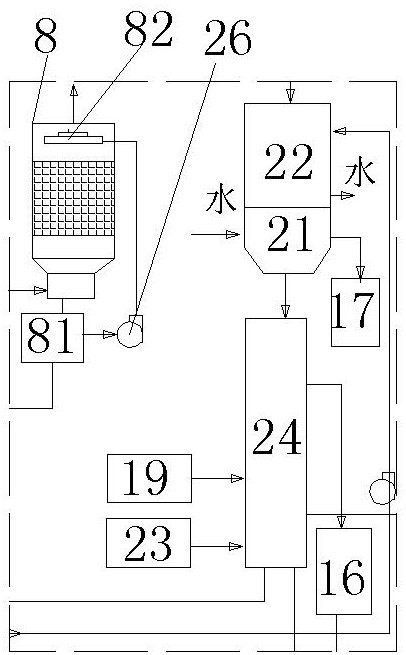

[0062] Example 1. Such as Figure 1-3 Shown, the technique of producing ammonium sulfite and byproduct thiosulfate mixed nutrient solution is characterized in that, comprises the steps:

[0063] The sulfur is put into the sulfur incinerator 1 for combustion to produce flue gas rich in high-concentration sulfur dioxide gas; the flue gas enters the cyclone separation tower 2 for dust removal, and the flue gas after dust removal enters the heat exchanger 3 to reduce the temperature to 60-70 ℃; the flue gas enters the washing and purifying tower 4, and the structure of the washing and purifying tower 4 is similar to that of the cyclone separation tower 2, except that an atomizing nozzle 41 is arranged on the upper part, and the atomized water ejected by the atomizing nozzle 41 is used to remove the solids in the flue gas. The substance is washed; then the flue gas enters the first-level absorption tower 5, and the first-level absorption tower 5 includes at least a spray nozzle 10...

Embodiment 2

[0107] Example 2. Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that the liquid fertilizer generating kettle 24 is connected to the gas inlet of the secondary absorption tower 6 through a pipeline, and a vacuum pump 27 and a pressure stabilizing valve 28 are arranged on the pipeline; The device lowers the temperature of the sulfur incinerator, so that when the sulfur incinerator burns, the temperature of the furnace body is kept at 800 degrees Celsius, and the water vapor generated by the steam generator is passed into the mixed nutrient solution generating kettle to keep the liquid temperature in the mixed nutrient solution generating kettle within 60 minutes Slowly increase to 85 degrees Celsius, and pass the gas generated by the mixed nutrient solution generating kettle into the secondary absorption tower; continue to feed water vapor into the mixed nutrient solution generating kettle to make the liquid temperature in the mixed nut...

Embodiment 3

[0110] Example 3. Such as Figure 6-7 As shown, the difference between the present embodiment and Embodiment 1 is that the liquid fertilizer generating kettle 24 is connected to the gas inlet of the three-stage absorption tower 7 through a pipeline, and the pipeline is provided with a vacuum pump 27 and a pressure stabilizing valve 28; The alkali that generates kettle 24 is potassium hydroxide. A steam generator is used to cool down the sulfur incinerator, so that when the sulfur incinerator burns, the temperature of the furnace body is maintained at 760 degrees Celsius, and the water vapor generated by the steam generator is passed into the mixed nutrient solution generating kettle to make the liquid temperature in the mixed nutrient solution generating kettle Slowly rise to 82 degrees centigrade in 50 minutes, the gas that the mixed nutrient solution generating kettle generates is passed into the three-stage absorption tower; Continue to feed water vapor into the mixed nutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com