A kind of preparation method of z-form bismuth-based photocatalyst

A photocatalyst, bismuth-based technology, applied in the field of nanomaterials, can solve the problems of cost control and quality optimization obstacles, and achieve the effect of high redox potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

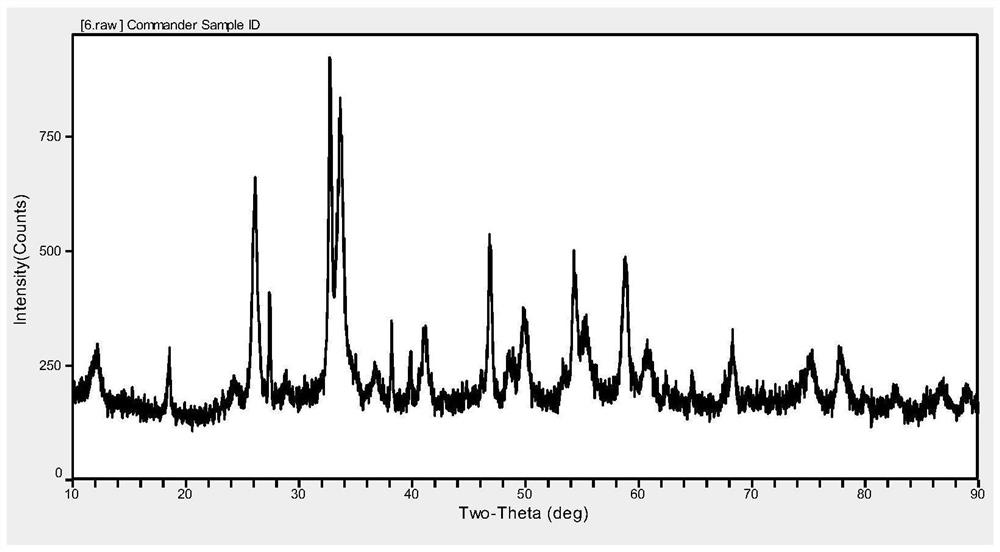

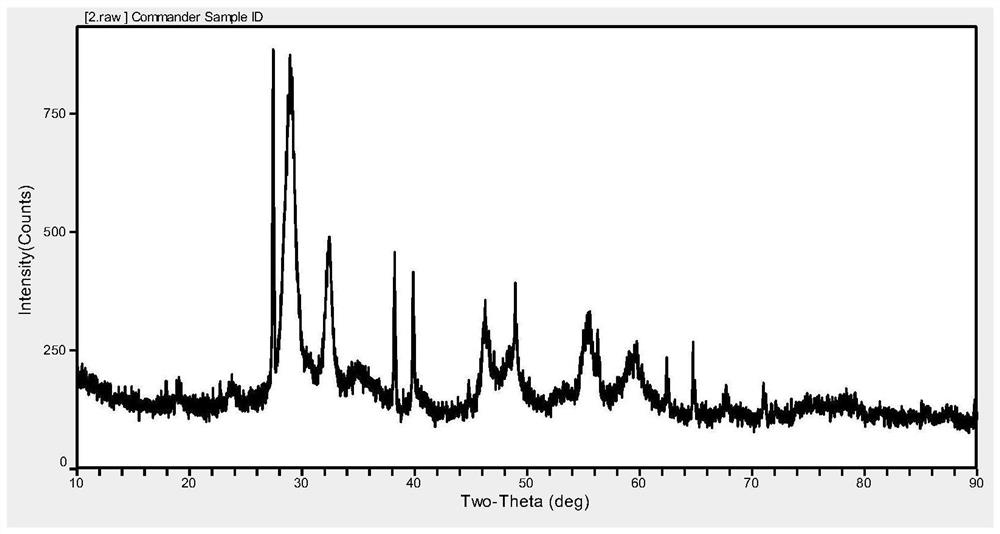

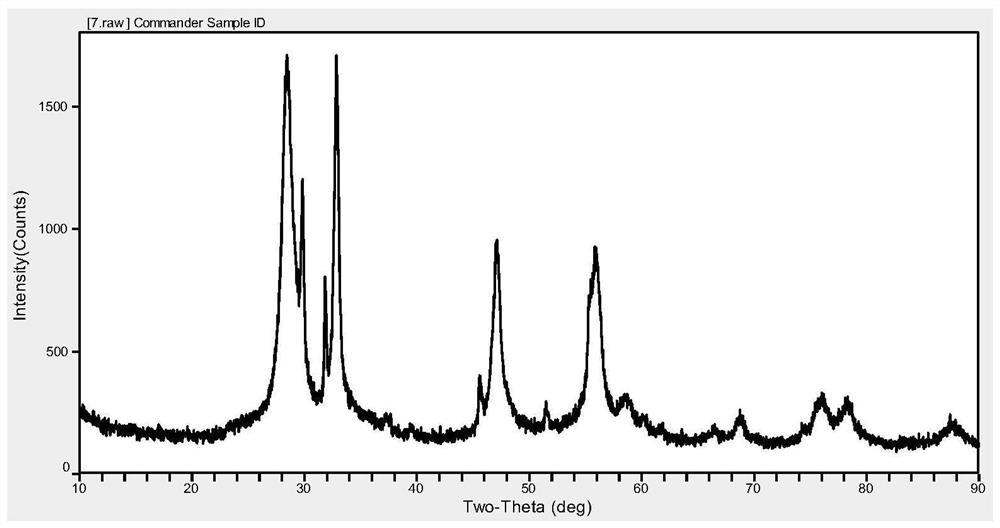

Image

Examples

Embodiment 1

[0039] A preparation method of a Z-form bismuth-based photocatalyst, the method steps are as follows:

[0040] (1) Preparation of bismuth iodide precursor

[0041] Disperse 2.5 mmol of bismuth nitrate in 15 mL of ethylene glycol, dissolve it completely after stirring for 1 h, add it to 5 mL of potassium iodide aqueous solution containing 1 mmol of potassium iodide, and continue to stir for 1 h to fully react to obtain reaction solution A.

[0042] (2) Preparation of bismuth iodide-bismuth tungstate precursor

[0043] Add 10 mL of sodium tungstate aqueous solution containing 1 mmol sodium tungstate to the reaction solution A prepared in step (1), and continue stirring for 0.5 h to obtain a reaction solution with a reducing chemical atmosphere, which contains bismuth iodide-bismuth tungstate precursor.

[0044] (3) Transfer the reaction solution obtained in step (2) to a hydrothermal reaction kettle with a volume of 50 mL, and react at 140° C. for 10 hours; after naturally coo...

Embodiment 2

[0047] A preparation method of a Z-form bismuth-based photocatalyst, the method steps are as follows:

[0048] (1) Preparation of bismuth iodide precursor

[0049] Disperse 2.3 mmol of bismuth nitrate in 15 mL of dimethyl sulfoxide, dissolve it completely after stirring for 1 h, add it to 5 mL of sodium iodide aqueous solution containing 1 mmol of sodium iodide, continue to stir for 1 h, and fully react to obtain a reaction solution, wherein A precursor containing bismuth iodide.

[0050] (2) Preparation of bismuth iodide-bismuth vanadate precursor

[0051] To the reaction solution obtained in step (1), add 5 mL of sodium vanadate aqueous solution containing 1 mmol of sodium vanadate, continue stirring for 0.5 h, add 5 mL of ascorbic acid aqueous solution containing 0.3 mmol of ascorbic acid to obtain a reaction solution with a reducing chemical atmosphere , which contains bismuth iodide-bismuth vanadate precursor.

[0052] (3) Transfer the reaction solution obtained in ste...

Embodiment 3

[0055] A preparation method of a Z-form bismuth-based photocatalyst, the method steps are as follows:

[0056] (1) Preparation of bismuth iodide precursor

[0057] Disperse 2.2 mmol of bismuth nitrate in 15 mL of water, stir for 1 hour and disperse evenly, add 5 mL of sodium iodide ethylene glycol solution containing 1 mmol of sodium iodide, continue to stir for 1 hour, and fully react to obtain a reaction solution, which contains iodine Oxybismuth precursor.

[0058](2) Preparation of bismuth iodide-bismuth ferrite precursor

[0059] To the reaction solution obtained in step (1), add 5 mL of ferric chloride ethylene glycol solution containing 1 mmol of ferric chloride, continue stirring for 0.5 h, and add 5 mL of aqueous glucose solution containing 0.2 mmol of glucose to obtain a reducing chemical solution. Atmospheric reaction solution containing bismuth iodide-bismuth ferrite precursor.

[0060] (3) Transfer the reaction solution obtained in step (2) to a hydrothermal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com