Nanometer titanium silicalite molecular sieve TS-1 as well as preparation method and application thereof

A silicon molecular sieve, TS-1 technology, applied in the direction of molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic silicates, etc., can solve the problem of reducing the grain size of titanium silicon molecular sieves, and achieve excellent catalytic performance, effective utilization, and effective raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

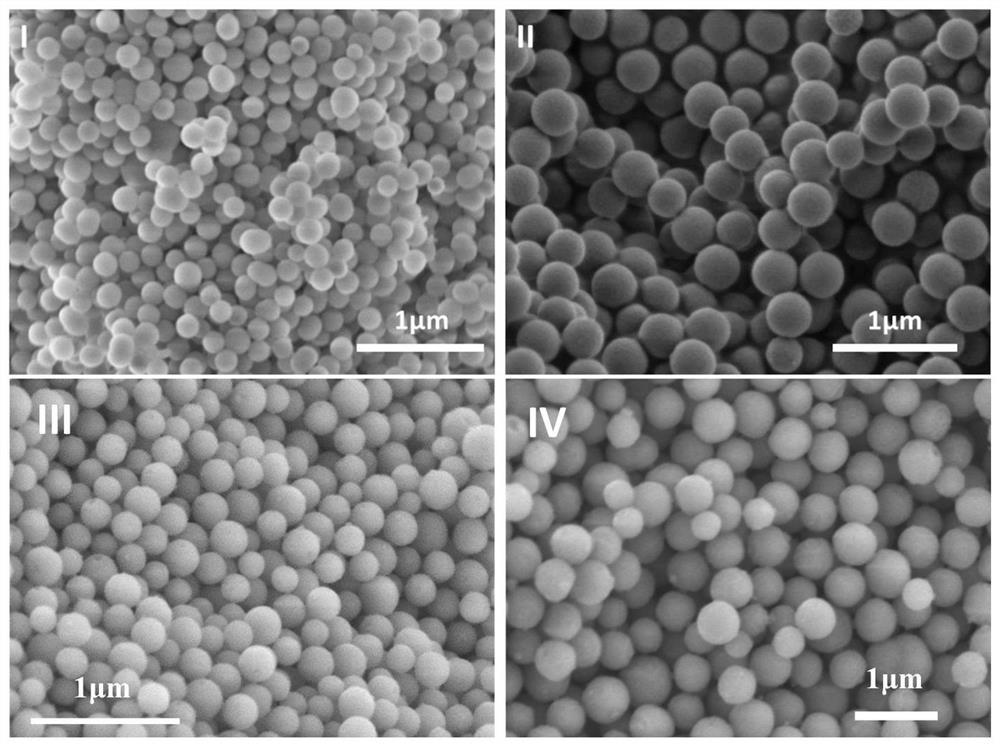

[0047] Embodiment 1: Preparation of amorphous titanium dioxide / silicon samples MTS-I~MTS-IV

[0048] Under the condition of stirring at 50°C, dissolve 0.20g of cetyltrimethylammonium bromide (structure directing agent) in 60mL of deionized water and ethanol solution, then add ammonia water to the solution to adjust the pH value of the solution, after stirring Add 1.0 g of ethyl orthosilicate and 0.05 g of tetrabutyl titanate, and continue stirring for 2 h. After the product was filtered, washed, washed with water, and dried, it was calcined at 550° C. for 6 hours to remove the structure-directing agent and obtain a white powder, labeled as sample MTS-I.

[0049] According to Table 1, the pH value in the synthesis process and the addition amount of tetraethyl orthosilicate and butyl titanate are adjusted, and the particle diameter of the resulting product can change, and the obtained samples MTS-I, MTS-II, and sample MTS-III , Sample MTS-IV and its performance parameters are s...

Embodiment 2

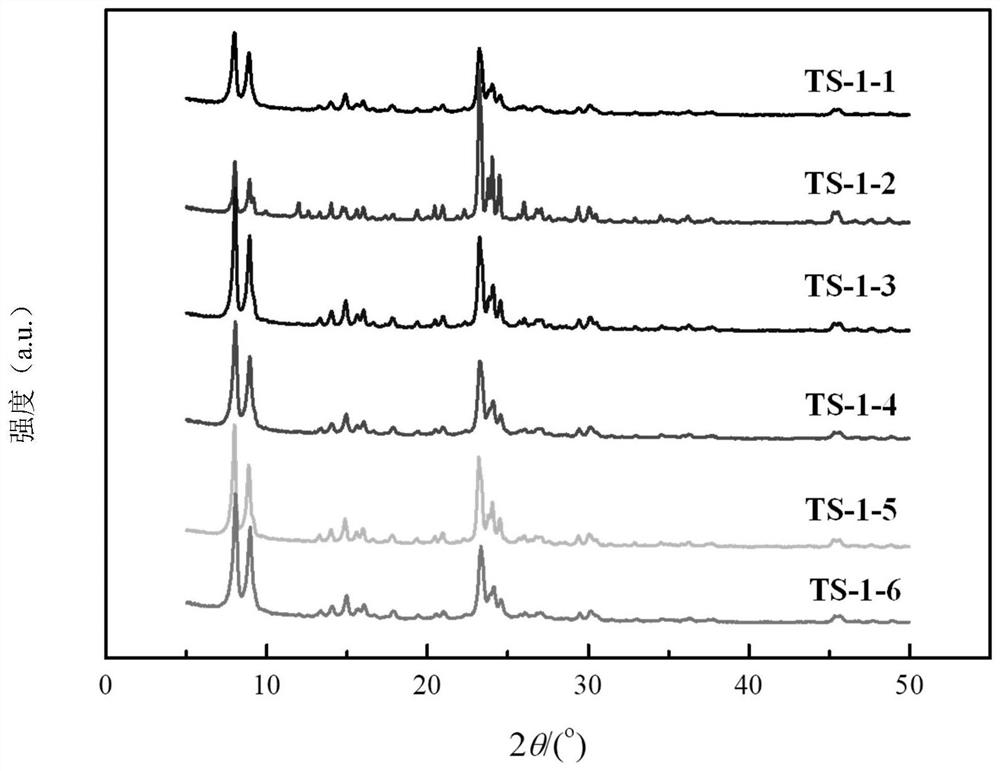

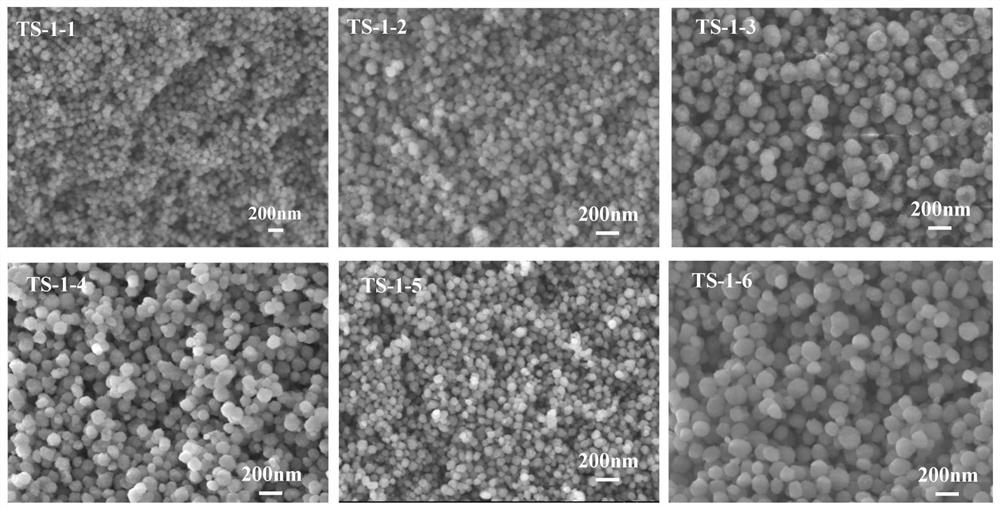

[0054] Embodiment 2: Preparation of samples TS-1-1~TS-1-6

[0055] First, weigh the amorphous titanium dioxide / silicon composite, organic amine, inorganic alkali source, and deionized water prepared in Example 1 according to the conditions listed in Table 1.

[0056] The organic amine and the inorganic alkali source are added into the deionized water, stirred and dissolved to obtain a mixed solution. The above solution was used to impregnate amorphous titanium oxide / silicon spheres, wherein the solid-to-liquid volume ratio of titanium dioxide / silicon spheres to the mixed solution was 1:1, and a solid mixture was obtained after drying at room temperature for a period of time. The above solid mixture was transferred to the upper plate of the stainless steel autoclave, and water was added to the bottom of the autoclave. Seal the stainless steel reaction kettle, put it in an oven, and crystallize at 130-180°C for 24-96 hours. Cool rapidly after the reaction, separate the solid p...

Embodiment 3

[0062] Embodiment 3: 1-hexene epoxidation reaction evaluation

[0063] In the experiment, the TS-1 sample was synthesized by the traditional hydrothermal method, and the ratio of the synthetic gel was 1SiO 2 :0.25TPAOH:0.02TiO 2 :35H 2 O. Concrete gel preparation steps: first, add tetrapropylammonium hydroxide (TPAOH) to deionized water at room temperature and stir; after it is fully dissolved, slowly add a certain amount of ethyl orthosilicate and butyl titanate; After continuing to stir at room temperature for 24h, the raw material was transferred to a stainless steel synthesis kettle and crystallized at 150°C for 24h. The resulting solid product was centrifuged, washed, dried overnight at 110°C, and finally calcined at 550°C for 6 hours to remove the organic template, which was named conv-TS-1.

[0064] The prepared conv-TS-1 and the nano-TS-1 molecular sieve prepared in Example 2 were evaluated for the epoxidation reaction of 1-hexene. The specific steps of reaction e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com