Post-treatment method for molecular sieve modification

A molecular sieve and modification technology, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve catalyst, molecular sieve and base exchange compound, etc., can solve problems such as acid loss, uneven distribution of mesopores, collapse of molecular sieve crystal structure, etc., and achieve improved selection The modification method is simple and convenient, and the effect of improving the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of the pretreated Beta molecular sieve: first mix and soak the Beta raw powder and pyridine, the mass ratio of the two is 1:20, the soaking time of the Beta raw powder and pyridine is 12h, filter or centrifuge the soaked molecular sieve to obtain molecular sieve powder, and wash with distilled water Remove physically adsorbed pyridine molecules; wash with water and then further dry at 150°C for 2 hours; finally, high-temperature carbonization in a tube furnace at 700°C for 2 hours.

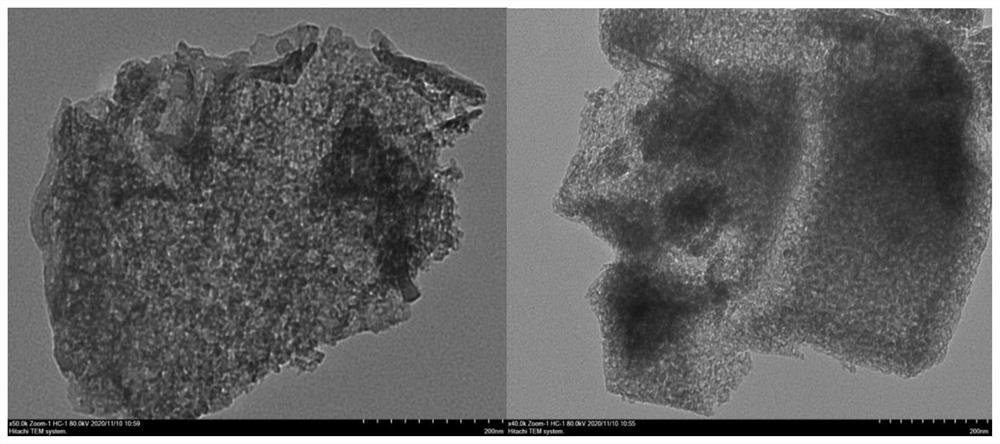

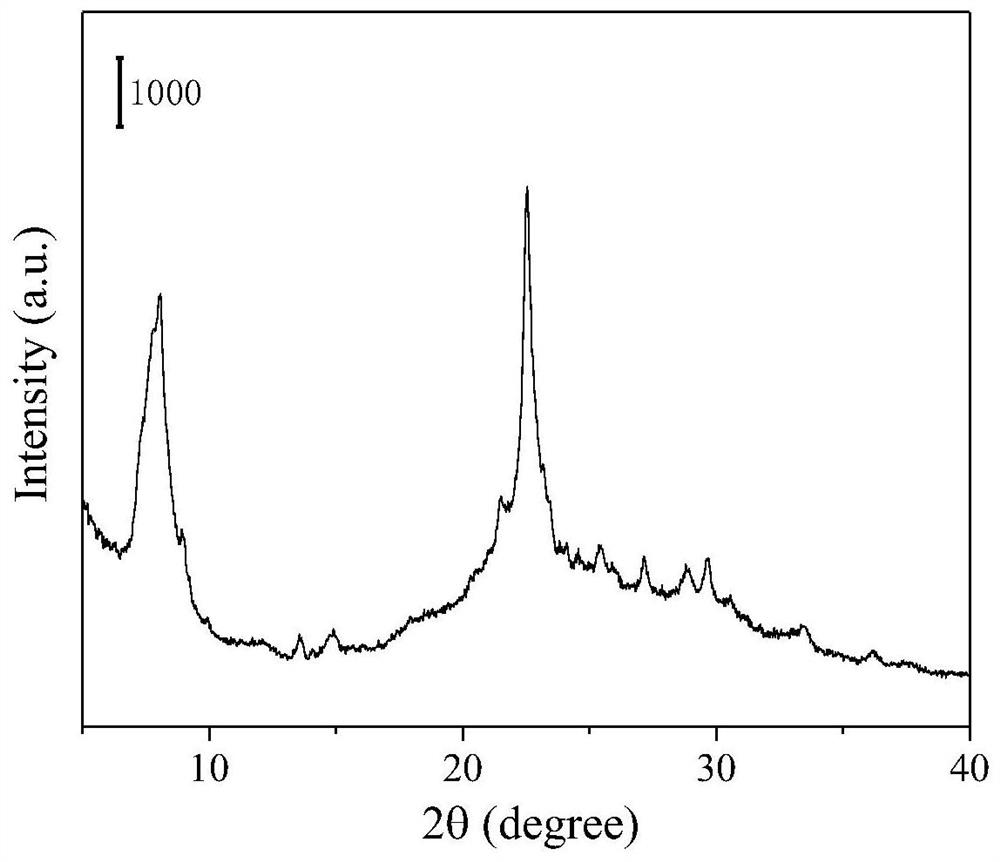

[0024] The pretreated Beta molecular sieve and sodium hydroxide solution (0.4mol / L) were mixed and added into a three-necked flask at a mass ratio of 1:20, and the mixture was dissolved at 70 Heat alkali treatment at ℃ for 2 hours, wash and filter the obtained product several times with deionized water, then dry at 100 ℃ for 5 hours, and roast at 550 ℃ for 5 hours to obtain the modified Beta molecular sieve. Depend on figure 1 (TEM) shows that the distribution of mesopores ...

Embodiment 2

[0035] Preparation of pretreated SAPO-11 molecular sieve: first degass and remove impurities from SAPO-11 raw powder, treat at 100°C for 8 hours; then mix and soak with lutidine, the mass ratio of the two is 1:5, The soaking time of the powder in lutidine is 1h; the soaked molecular sieve is filtered or centrifuged to obtain molecular sieve powder, and washed with distilled water to remove the physically adsorbed pyridine molecules; after washing, it is further dried at 100°C, and the drying time is 12h; finally, high-temperature carbonization in a tube furnace, the carbonization temperature is 300°C, and the carbonization time is 8h.

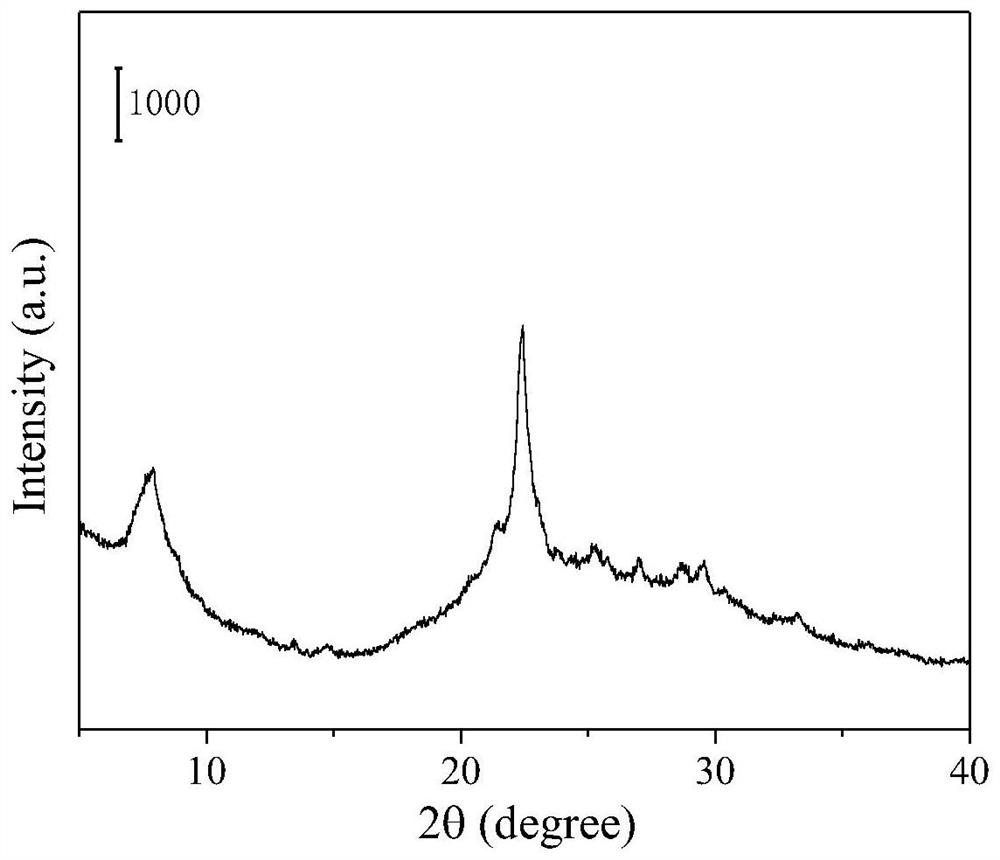

[0036] Mix the pretreated SAPO-11 molecular sieve with tetrapropylammonium hydroxide (the concentration of lye is 0.1mol / L) according to the mass ratio of 1:5 and add it to the three-necked flask. The mixture solution was heated and alkali-treated at 90°C for 1 hour, the product obtained was washed and filtered several times with deionized wate...

Embodiment 3

[0038] Preparation of pretreated mordenite molecular sieve: first degass and remove impurities from mordenite raw powder, and treat it at 400°C for 1 hour; then mix and soak with aniline, the mass ratio of the two is 1:30, and the mordenite raw powder is soaked in aniline for 24 hours The soaked molecular sieve is filtered or centrifuged to obtain molecular sieve powder, and the pyridine molecules physically adsorbed are washed with distilled water; after washing, the drying temperature is 120 °C, and the drying time is 1 hour; finally, the tube furnace is carbonized at high temperature, carbonized The temperature is 1000°C and the carbonization time is 1h.

[0039] Mix the pretreated mordenite molecular sieve and potassium hydroxide solution (6mol / L) in a mass ratio of 1:20 into a three-necked flask, and put the mixture solution at 50°C under the conditions of microwave power of 600w and magnetic stirring After heating and alkali treatment at low temperature for 12 hours, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com