An anti-adsorption type concrete glue reducer and its application

A concrete and glue reducer technology, applied in the field of concrete admixture, can solve the problems of reducing the effective content of polycarboxylate water reducer, reducing the dispersion efficiency of polycarboxylate water reducer, and performance loss, so as to reduce the amount of cement, resist The effect of improving permeability and crack resistance and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present embodiment provides a kind of anti-adsorption type concrete glue reducer, prepares according to the following steps:

[0020] (1) 8kg of methacrylic acid emulsion, 0.6kg of polycarboxylate water-reducing agent, 0.5kg of cellulose ether and 90.9kg of water are mixed to obtain leveling water-retaining agent TC-LPB.

[0021] (2) at 30 ℃, with leveling water retention agent TC-LPB 4kg, castor oil phosphate 7kg, polyamine polyether methylidene phosphamide 4kg, maleic anhydride-acrylic acid copolymer 4kg, sodium formate 5kg, thiocyanate 7kg of sodium, 35kg of triethanolamine and 34kg of water were added to the reaction kettle respectively, mixed and stirred for 1h, and the setting stirring rate was 300r / min; wherein the weight-average molecular weight of the maleic anhydride-acrylic acid copolymer was 8000.

[0022] (3) Cool the mixed solution to room temperature to prepare anti-adsorption type concrete glue reducing agent TC-KJ-01.

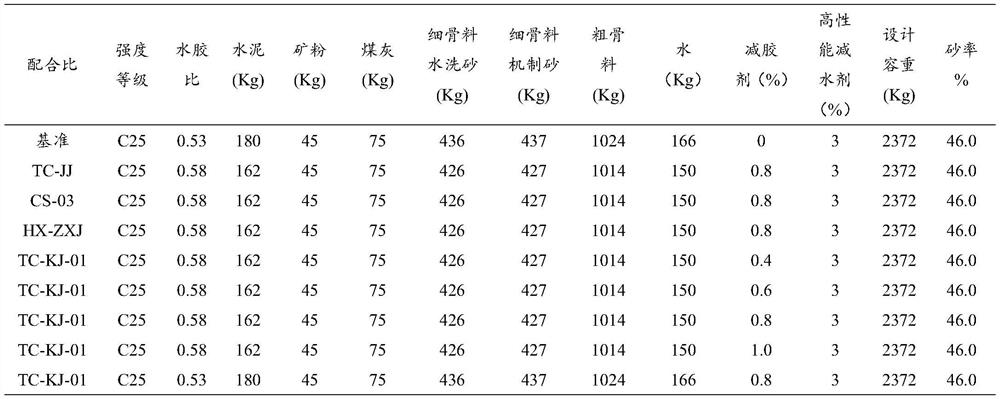

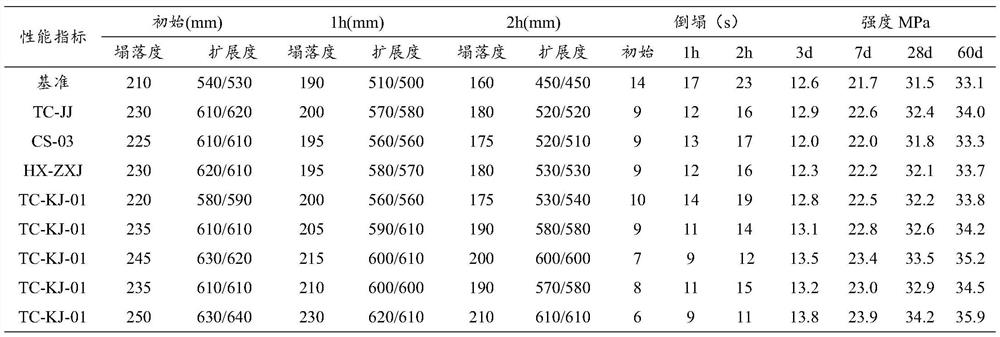

[0023] (4) The anti-adsorpti...

Embodiment 2

[0026] The present embodiment provides a kind of anti-adsorption type concrete glue reducer, prepares according to the following steps:

[0027] (1) 7.2kg of methacrylic acid emulsion, 0.7kg of polycarboxylic acid water-reducing agent, 0.6kg of cellulose ether and 91.5kg of water are mixed to obtain leveling water-retaining agent TC-LPB.

[0028] (2) at 25 ℃, with leveling water retention agent TC-LPB 5kg, isooctyl phosphate 8kg, ethylenediamine tetramethylene phosphine 5kg, maleic anhydride-acrylic acid copolymer 5kg, sodium formate 6kg, thiocyanate 8kg of sodium, 25kg of triethanolamine and 38kg of water were added to the reaction kettle respectively, mixed and stirred for 4h, and the stirring rate was set to be 100r / min; wherein the weight-average molecular weight of the maleic anhydride-acrylic acid copolymer was 6000.

[0029] (3) Cool the mixed solution to room temperature to prepare anti-adsorption type concrete glue reducing agent TC-KJ-02.

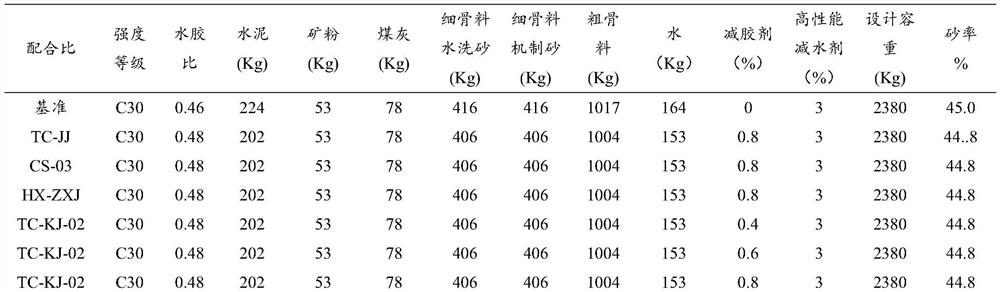

[0030] (4) The anti-adsor...

Embodiment 3

[0033] An anti-adsorption type concrete glue reducing agent of the present embodiment is prepared according to the following steps:

[0034] (1) 6.5kg of methacrylic acid emulsion, 0.8kg of polycarboxylate water-reducing agent, 0.7kg of cellulose ether and 92kg of water are mixed to obtain leveling water-retaining agent TC-LPB.

[0035] (2) at 40 ℃, with leveling water retention agent TC-LPB 6kg, alkyl phosphate 9kg, hexamethylene diamine tetramethylene phosphine 6kg, maleic anhydride-acrylic acid copolymer 6kg, sodium formate 7kg, sodium thiocyanate 10kg, 30kg of triethanolamine and 36kg of water were added to the reaction kettle respectively, mixed and stirred for 6h, and the setting stirring rate was 400r / min; wherein the weight-average molecular weight of the maleic anhydride-acrylic acid copolymer was 4000.

[0036] (3) Cool the mixed solution to room temperature to prepare anti-adsorption type concrete glue reducing agent TC-KJ-03.

[0037] (4) The above-prepared anti-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com