Novel lithium-sulfur battery material applied to energy storage system

A technology for lithium-sulfur batteries and energy storage systems, applied in lithium batteries, nanotechnology for materials and surface science, battery electrodes, etc. Short life and other problems, to achieve high discharge performance, excellent coulombic efficiency, and promote the effect of fixation and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

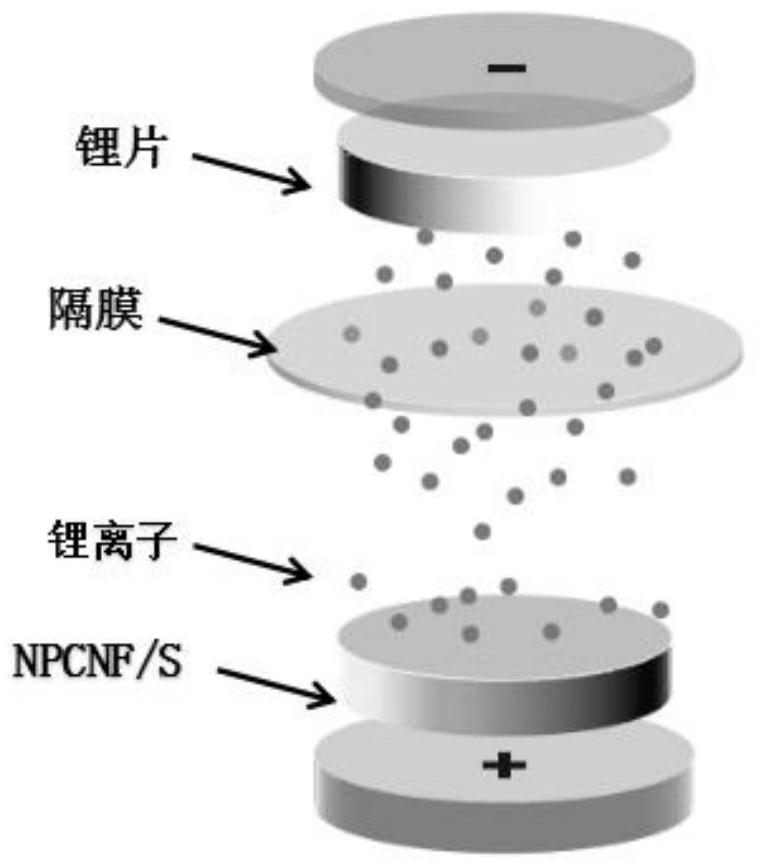

[0036] A method for manufacturing a battery for an energy storage charging system, comprising the following steps:

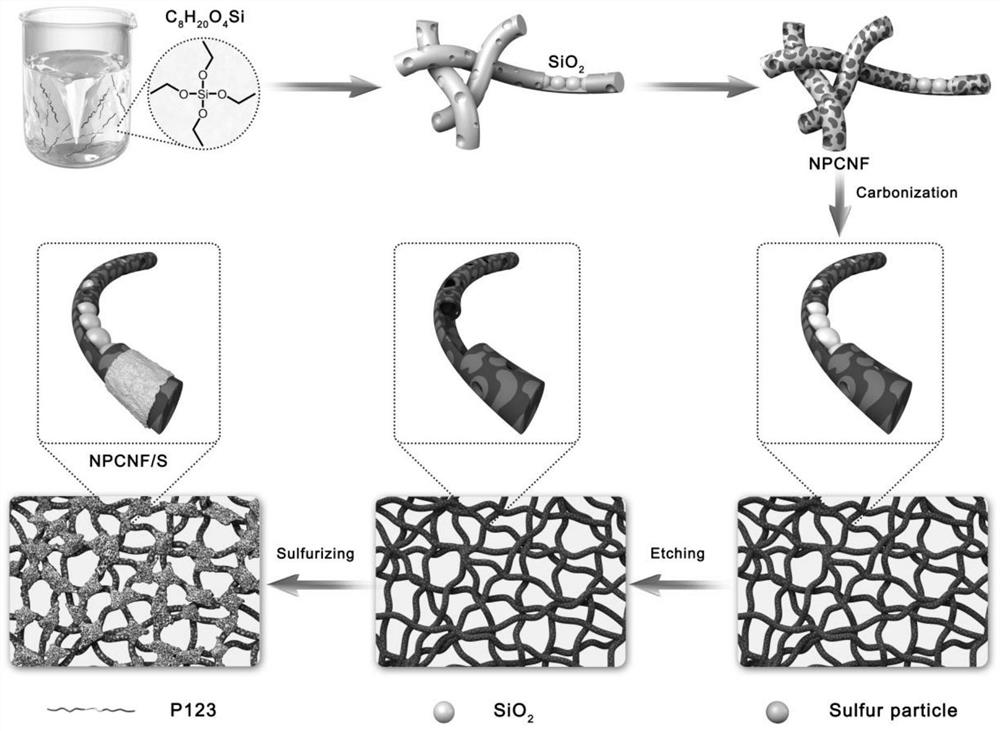

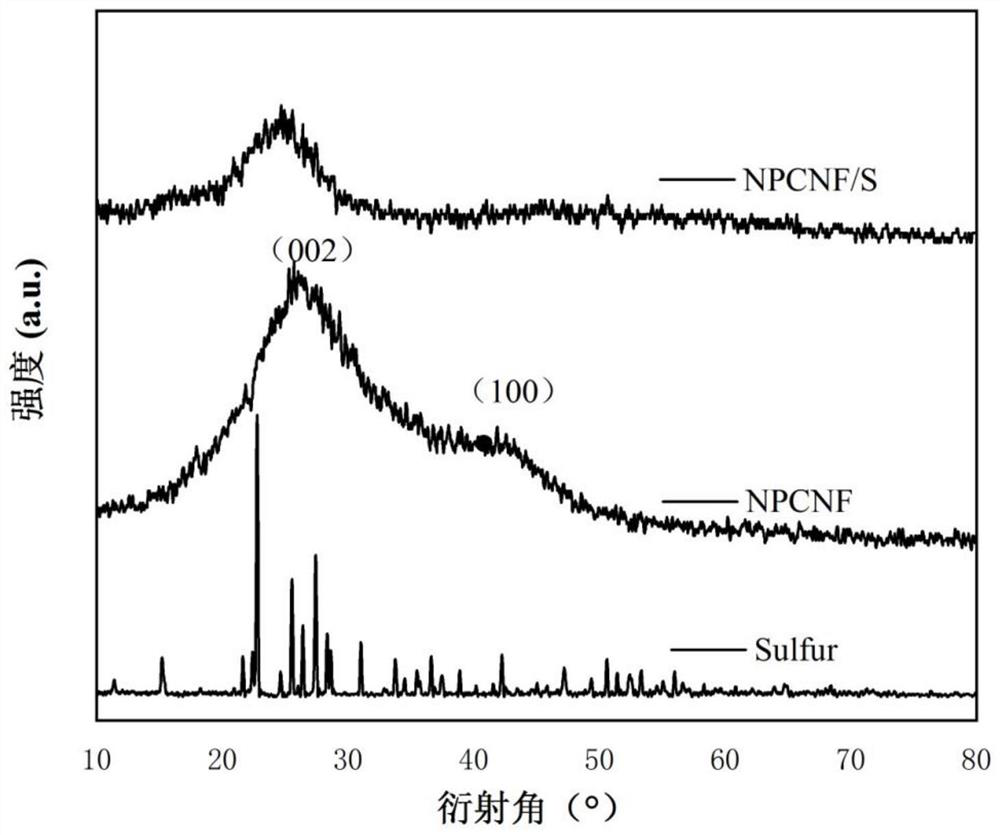

[0037] The first step: making a composite cathode material of nitrogen-doped porous carbon fiber.

[0038] A. Mix 1g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) with 10ml of tetraethyl orthosilicate (C 8 h 2 OO 4Si) Stir until completely dissolved to obtain solution A, wherein the P123 material can spontaneously form multimolecularly aggregated micelles in the solution, C 8 h 2 OO 4 Si serves as a carbon skeleton template.

[0039] B. With ethanol (C 2 h 5 OH) and concentrated hydrochloric acid (HCl) as a dispersant, add 40mL C 2 h 5 OH, 0.625 mL of HCl, and stirred for 10 min to obtain B solution.

[0040] C. Add 5 mL of deionized water to solution B, and stir for 2 hours to obtain solution C.

[0041] D.C. 2 h 4 N 4 As a carbon and nitrogen source, add 4 g of C to the C solution 2 h 4 N 4 Solution N w...

Embodiment 2

[0054] A method for manufacturing a battery for an energy storage charging system, comprising the following steps:

[0055] The first step: making a composite cathode material of nitrogen-doped porous carbon fiber.

[0056] A. Mix 1g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) with 20ml of tetraethyl orthosilicate (C 8 h 2 OO 4 Si) Stir until completely dissolved to obtain solution A.

[0057] B. With ethanol (C 2 h 5 OH) and concentrated hydrochloric acid (HCl) as a dispersant, add 40mL C 2 h 5 OH, 0.475 mL of HCl, and stirred for 10 min to obtain B solution.

[0058] C. Add 10 mL of deionized water to solution B, and stir for 2 hours to obtain solution C.

[0059] D.C. 2 h 4 N 4 As a carbon and nitrogen source, add 5 g of C to the C solution 2 h 4 N 4 Solution N was obtained, and the solution N was heated and stirred for 1.5 h and evaporated to dryness to obtain sample D.

[0060] E. Take the D sample and heat it at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| Reversible discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com