Preparation and application method of stepped pore molecular sieve for refining and separating phase change wax

An application method and molecular sieve technology, which are applied in the fields of petroleum wax refining, chemical instruments and methods, heat exchange materials, etc., can solve the problems of high isoparaffin content, low phase change enthalpy value, and no relevant reports, and reduce the The effect of isoparaffin content, reduction of energy consumption of equipment, and expansion of selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment provides a kind of preparation method of Beta molecular sieve former powder, comprises the following steps:

[0048] Beta molecular sieve raw powder was synthesized according to the method disclosed in the example of US Patent No. 3,308,069. First add 0.10g NaAlO 2 (chemically pure, Al 2 o 3 , 41wt%) solid and 3.62g TEAOH solution (industrial grade, 20wt%) preparation solution, then add 3.28g silica sol (industrial grade, SiO 2 ≥ 30wt%), mix uniformly to form a gel, and the molar ratio of each material is: SiO 2 / Al 2 o 3 =40, Na 2 O / SiO 2 =0.004, TEA 2 O / SiO 2 =0.15,H 2 O / SiO 2 = 17.6, continue to stir for about 1 hour, put the prepared gel into a stainless steel reactor with a polytetrafluoroethylene liner, crystallize at 150 ° C for about 4 days, cool to room temperature, filter and wash.

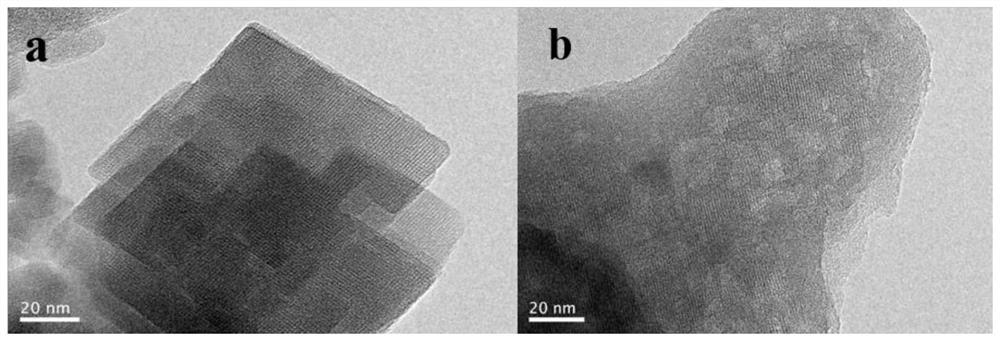

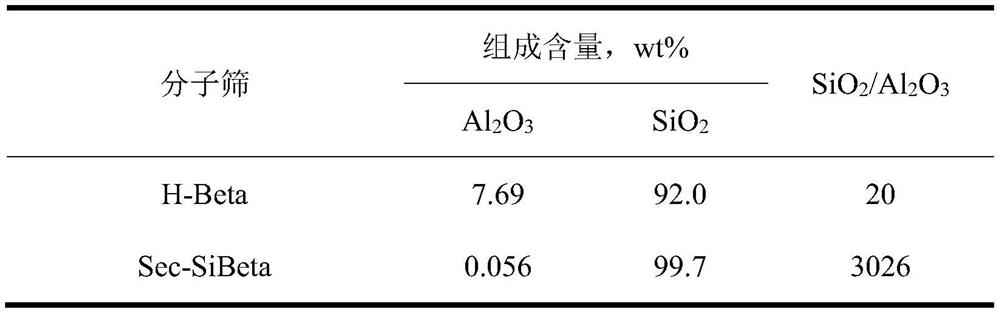

[0049] The Beta molecular sieve former powder TEM photograph that embodiment 1 prepares sees figure 1 (a), the physical and chemical properties...

Embodiment 2

[0051] This embodiment provides a preparation method for the synthesis of a stepped pore Sec-SiBeta molecular sieve, comprising the following steps:

[0052] (1) Preparation of high silicon Si-Beta molecular sieve

[0053] Firstly, beta raw powder and ammonium chloride aqueous solution (2mol / L, 80°C) were ion-exchanged for 3 hours according to the solid-to-liquid ratio of 1:10, and the product was filtered and washed with deionized water and dried in an oven at 100°C for 24 hours; Prepare H-Beta zeolite by roasting in muffle furnace (air atmosphere, 560°C) for 4h to remove organic template; weigh 1.0g H-Beta zeolite and add 20mL HNO 3 Solution (pH=1.0, 13mol / L), stirred continuously at 100°C for 8h; the treated liquid was cooled to room temperature to filter out the acid solution, washed with deionized water until pH=6.0-7.0, filtered, dried at 100°C for 24h, the product was named Si -Beta.

[0054] (2) Secondary crystallization to synthesize step-pore Sec-SiBeta molecular s...

Embodiment 3

[0063] This embodiment provides a method for preparing a stepped pore Sec-SiBeta molecular sieve adsorbent, comprising the following steps:

[0064] Mix the original powder of stepped hole Sec-SiBeta molecular sieve, kaolin, bentonite and sage powder according to the mass ratio of 92:6:1:1, add an appropriate amount of water, the amount of water is 12wt% of the solid powder, after stirring evenly, extrude with a screw Extruded into rods with a diameter of 1.6mm, dried at 90°C for 8 hours, heated to 550°C at a rate of 2°C / min and roasted for 4 hours, and the above-mentioned molecular sieve crystals were prepared in 0.6mol / L CaCl 2 The solution was ion-exchanged twice at 90°C for 2 hours each time, washed with suction to neutrality, dried at 110°C for 24 hours, and activated at 450°C for 3 hours to obtain the Sec-SiBeta molecular sieve strip adsorbent with stepped pores.

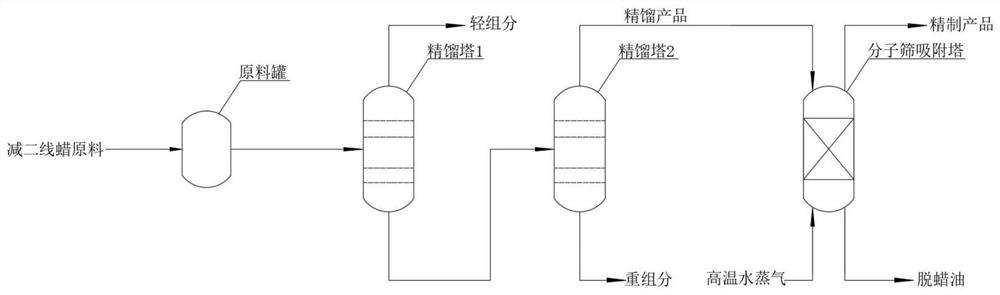

[0065] A high-quality phase-change wax product is prepared with refinery-reduced second-line oil as a liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com