Preparation method and application of cobalt tetrasulfide nickel and nickel-vanadium double-metal hydroxide composite material

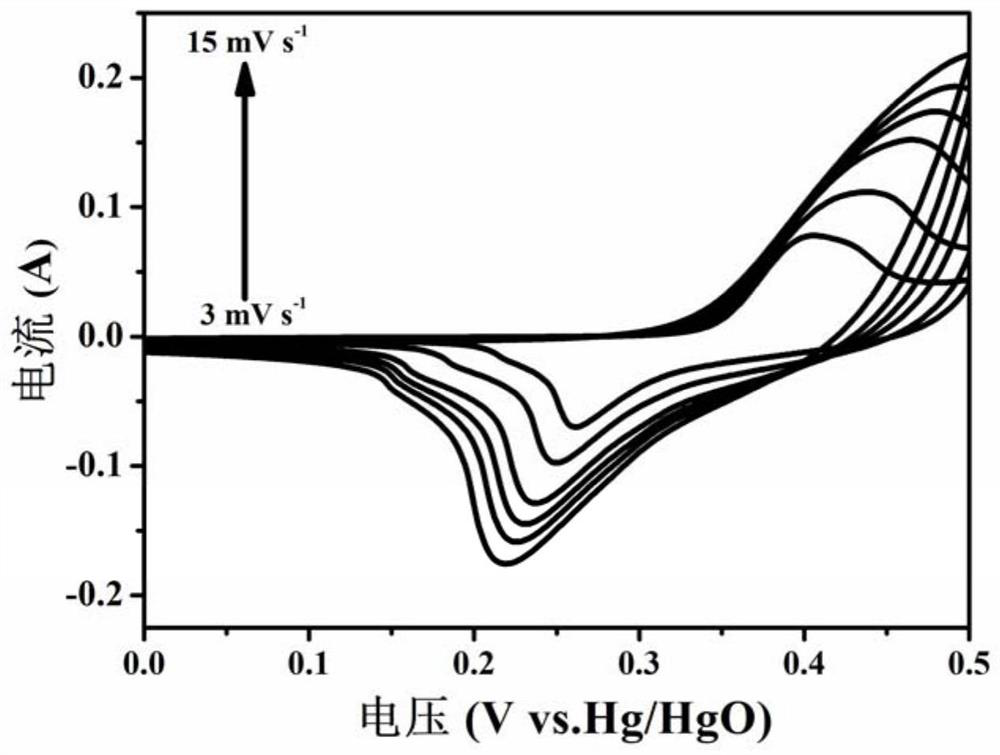

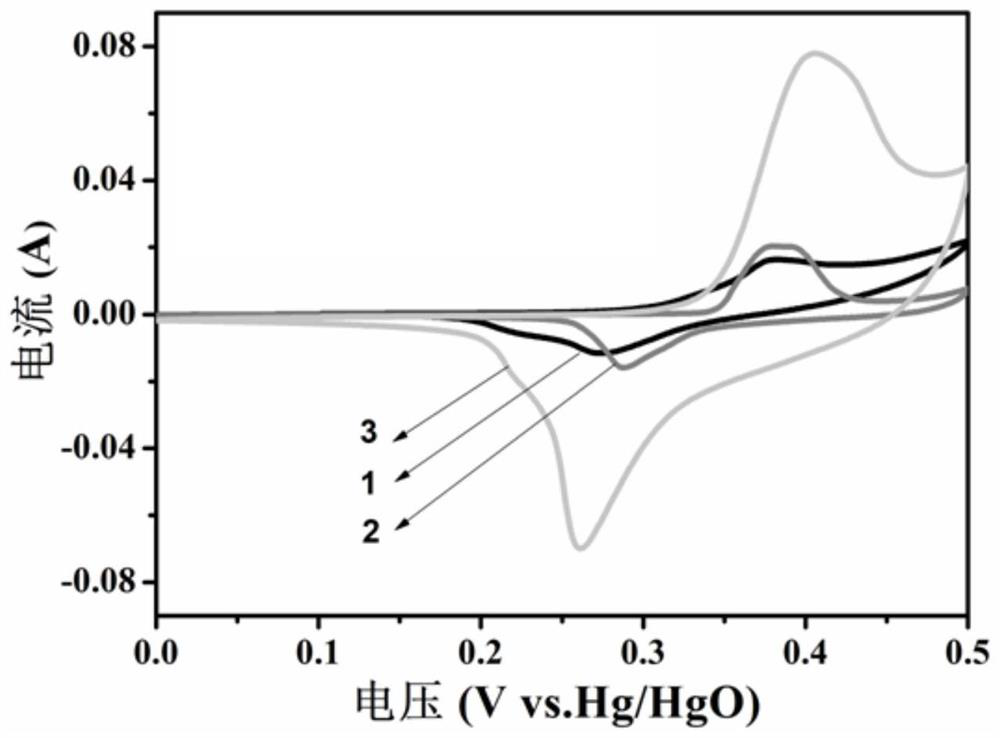

A technology of cobalt tetrasulfide and hydroxide, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of NiV-LDH ion transmission rate and electronic conductivity, poor conductivity of LDH, etc. , to achieve the effect of improving charging/discharging efficiency, low equipment requirements, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

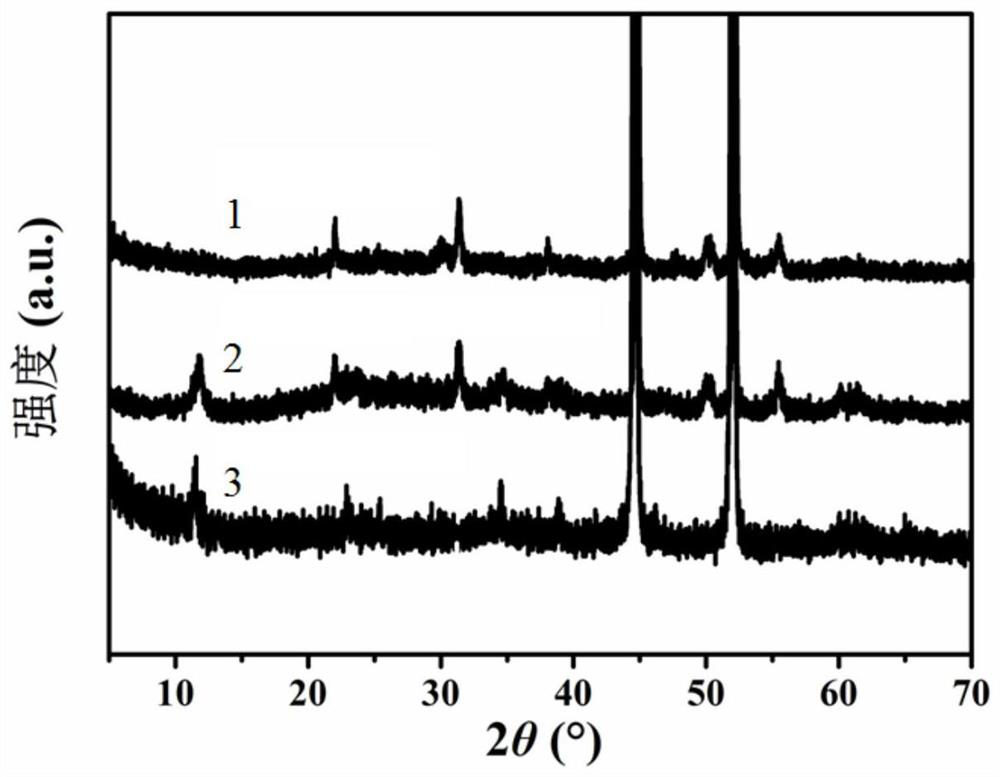

[0040] Specific embodiment one: a kind of preparation method of dicobalt nickel tetrasulfide@nickel vanadium double metal hydroxide composite material is completed according to the following steps:

[0041] 1. Preparation of NiCo precursor:

[0042] ①. Dissolving cobalt nitrate hexahydrate, nickel nitrate hexahydrate and urea in deionized water, stirring evenly to obtain mixture I;

[0043]The mol ratio of cobalt nitrate hexahydrate, nickel nitrate hexahydrate and urea described in step 1. is (1~2):(1~2):6;

[0044] ②. Cut the large pieces of foamed nickel into small pieces of foamed nickel, collect the small pieces of foamed nickel, and obtain the raw material of foamed nickel;

[0045] The thickness of the small foam nickel described in step 1.2 is 1cm, and the surface area is 3cm 2 ~5cm 2 ;

[0046] ③. Transfer the mixture I and nickel foam raw materials to a polytetrafluoroethylene autoclave, then carry out hydrothermal reaction, and finally cool naturally to room temp...

specific Embodiment approach 2

[0066] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the volume ratio of the amount of cobalt nitrate hexahydrate described in step one 1. to ionized water is (1mmol~2mmol): 80mL; step one 3. The temperature of the hydrothermal reaction described in is 80°C-120°C, and the time of the hydrothermal reaction is 5h-10h. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0067] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1 ④, first use deionized water to clean the reaction product I for 3 to 5 times, and then use absolute ethanol to clean the reaction product. I was washed 3 to 5 times, and finally the washed reaction product I was dried at a temperature of 70°C to 80°C and a drying time of 10h to 12h to obtain a NiCo precursor. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com