Nano-composite polypropylene composite material with high thermal conductivity, and preparation method thereof

A technology of nanocomposite and composite materials, which is applied in the field of nanocomposite polypropylene composite materials with high thermal conductivity and its preparation. It can solve the problems of increased working temperature, poor heat dissipation performance, and low thermal conductivity, and achieve thermal conductivity and thermal performance. Improvement, high thermal conductivity, excellent thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the high thermal conductivity functionalized nano zeolite / polypropylene composite material of the present invention mainly includes the following two steps:.

[0030] (1) Disperse amino-functionalized nano-zeolite particles in a solvent, add quantitative 3,5-diaminobenzoic acid and triphenyl phosphite, react at 110°C for 6 hours under a nitrogen atmosphere, centrifuge, wash, and dry Obtain hyperbranched polyarylamide graft functionalized nano zeolite particles;

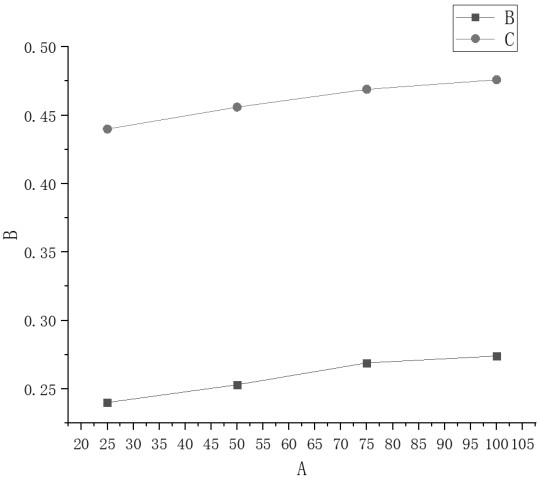

[0031] (2) Disperse the functionalized nano-zeolite particles grafted with hyperbranched polyaramid into ethanol solvent, and oscillate ultrasonically for 30 minutes; then heat the rheometer to 110°C, start the motor and put a certain amount of polypropylene pellets Carry out smelting, and after the pellets are fully melted, the nano-zeolite ethanol solution grafted with hyperbranched polyaramid and functionalized is added to the silo for mixing according to a certain doping ratio; aft...

Embodiment 1

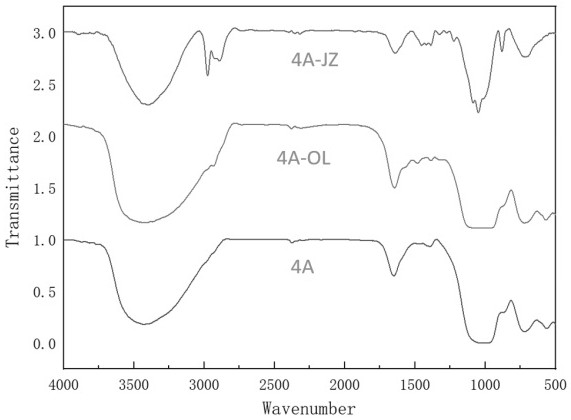

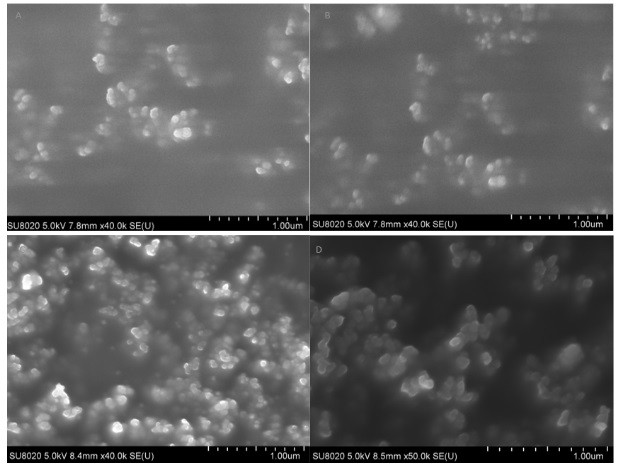

[0035] The preparation method of the high thermal conductivity functionalized 4A type zeolite / polypropylene polymer composite material in this example is as follows:

[0036] Pretreatment: Take 10g of 4A zeolite, mix it with 25ml of absolute ethanol, put it into a planetary ball mill and grind it for 10 hours to make the particles reach the nanometer level and disperse evenly, and then follow the ethanol: KH550: water = 7: The ratio of 2:1 is configured as 10ml solution A, 10g4A nano-zeolite particles are added to 250ml ethanol solution, after ultrasonic vibration for 30min, it is placed in a three-necked beaker, and then solution A is added to the three-necked beaker, at 65℃ The reaction was carried out for 10 h under a nitrogen atmosphere, and the obtained product was centrifuged, washed, and vacuum-dried to obtain an amino-functionalized 4A nano-zeolite.

[0037] (1) Disperse amino-functionalized 4A nano-zeolite particles in a solvent, add quantitative 3,5-diaminobenzoic ac...

Embodiment 2

[0044] The preparation method of the high thermal conductivity functionalized NaY type zeolite / polypropylene polymer composite material in this embodiment is as follows:.

[0045] Pretreatment: Take 10g of NaY zeolite, mix it with 25ml of absolute ethanol, and put it into a planetary ball mill for 10 hours of grinding, so that the particles reach the nanometer level and disperse evenly, and then according to ethanol: KH550: water = 7: The ratio of 2:1 is configured as 10ml solution A. Add 10g NaY nano-zeolite particles to 250ml ethanol solution. After ultrasonic vibration for 30min, put it in a three-necked beaker, then add solution A to the three-necked beaker, and heat at 65℃ React for 10 h under a nitrogen atmosphere, and the obtained product is centrifuged, washed, and vacuum-dried to obtain an amino-functionalized NaY nano-zeolite.

[0046] (1) Disperse amino-functionalized NaY-type nano-zeolite particles in a solvent, add quantitative 3,5-diaminobenzoic acid and tripheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com