Preparation method of super capacitor with asymmetric three-dimensional fork comb micro-column array electrode structure

A technology of supercapacitors and micro-pillar arrays, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of limited structure processing technology electrode film preparation process, unrealized three-dimensional structure electrodes, and electrode material chapping. , to widen the stability window, reduce the electron transmission distance, and reduce the electrode impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a method for preparing a supercapacitor with an asymmetric three-dimensional array electrode structure; the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

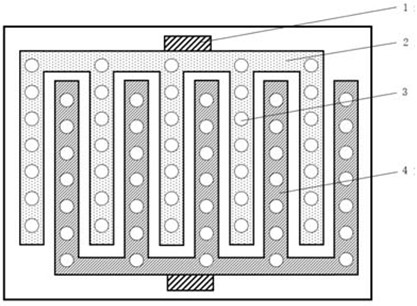

[0022] figure 1 The micro-supercapacitor structure shown is composed of a fork-comb positive electrode 2, a fork-comb negative electrode 4, and current collectors 1 on both sides of the electrodes. Among them, the fork-comb positive electrode 2 and the fork-comb negative electrode 4 are arranged with a microcolumn array 3; each microcolumn has a diameter of 70 μm and a height of 60 μm; the spacing of the microcolumns is 80 μm, and the width of the comb teeth is 80 μm.

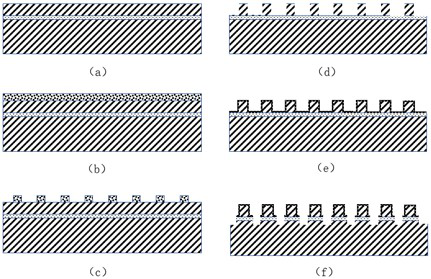

[0023] figure 2 Shown is the processing flow chart of the supercapacitor electrode microstructure, mainly including ICP plasma etching, sputtering coating and other processes. The specific process includes:

[0024] (a), SOI preparation: Selecting SOI ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com