Nano material, preparation method thereof, quantum dot light-emitting diode and preparation method of quantum dot light-emitting diode

A technology of quantum dot luminescence and nanomaterials, applied in the field of display, can solve the problems of complex preparation methods and single source of doped ZnO, and achieve the effects of reducing the injection barrier, promoting recombination, and promoting injection balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

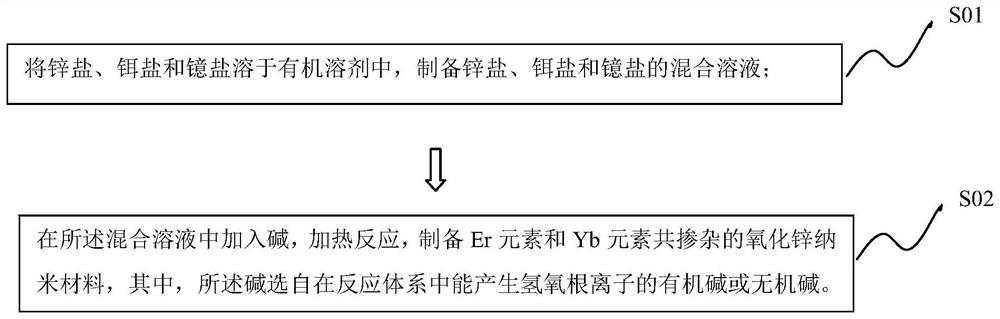

[0033] Correspondingly, combine figure 1 , The second aspect of the embodiment of the present invention provides a method for preparing a nanomaterial, comprising the following steps:

[0034] S01. Dissolving zinc salt, erbium salt and ytterbium salt in an organic solvent to prepare a mixed solution of zinc salt, erbium salt and ytterbium salt;

[0035] S02. adding alkali in the mixed solution, heating and reacting to prepare zinc oxide nanomaterials co-doped with Er elements and Yb elements, wherein the alkali is selected from organic bases or organic bases that can generate hydroxide ions in the reaction system Inorganic base.

[0036] The preparation method of the nanomaterial provided in the embodiment of the present invention only needs to dissolve zinc salt, erbium salt and ytterbium salt in an organic solvent, and then add alkali to react. The method is simple to operate and easy to realize large-scale preparation. More importantly, the nanomaterials prepared by the ...

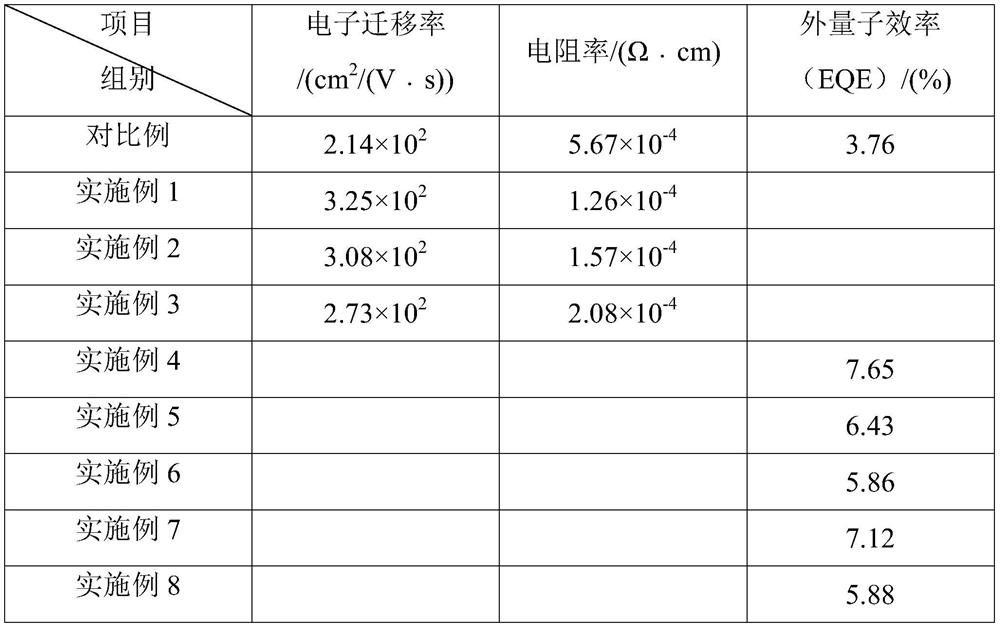

Embodiment 1

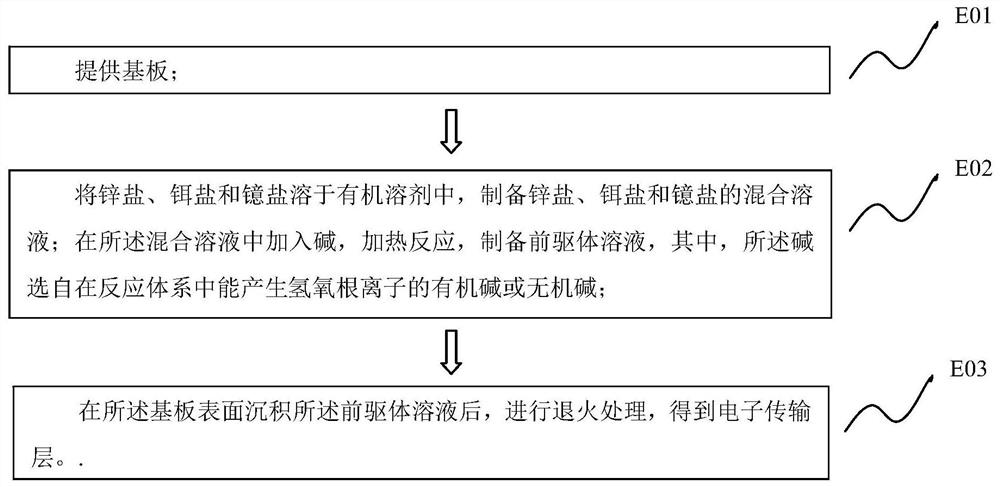

[0083] A method for preparing an electron transport thin film, comprising the following steps:

[0084] Add an appropriate amount of zinc sulfate, erbium sulfate and ytterbium sulfate into 50ml of ethanol, stir and dissolve at a temperature of 70°C to form a mixed solution with a total concentration of metal ions of 1mol / L. In the mixed solution, zinc ions and doped The molar ratio of ions (erbium ions and ytterbium ions) is 1:0.1, and the molar ratio of erbium ions and ytterbium ions is 2:1;

[0085] According to the molar ratio of hydroxide ions and metal ions of 1.8:1, an ethanol solution of potassium hydroxide was added to the mixed solution, and stirred at a temperature of 70°C for 4 hours to obtain a uniform transparent solution: Er -Yb / ZnO (Er-Yb / ZnO represents Er, Yb co-doped ZnO nanomaterial) solution;

[0086] After depositing the Er-Yb / ZnO solution on the surface of the substrate, annealing is performed at a temperature of 200° C. to obtain an electron transport th...

Embodiment 2

[0088] A method for preparing nanomaterials, comprising the steps of:

[0089] An appropriate amount of zinc nitrate, erbium nitrate and ytterbium nitrate are added in 50ml methanol, stirred and dissolved at 60°C, forming a mixed solution with a total concentration of metal ions of 1mol / L, in the mixed solution, zinc ions and dopant ions ( The molar ratio of erbium ion and ytterbium ion) is 1:0.15, and the molar ratio of erbium ion and ytterbium ion is 2.5:1;

[0090] According to the molar ratio of hydroxide ions and metal ions at a ratio of 2:1, a methanol solution of sodium hydroxide was added to the mixed solution, and stirred at a temperature of 60°C for 3 hours to obtain a uniform transparent solution: Er -Yb / ZnO (Er-Yb / ZnO represents Er, Yb co-doped ZnO nanomaterial) solution;

[0091] After depositing the Er-Yb / ZnO solution on the surface of the substrate, annealing is performed at a temperature of 150° C. to obtain an electron transport thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com