Electron transport material and preparation method thereof, photoelectric device and preparation method thereof

A technology for electron transport materials and optoelectronic devices, applied in the field of materials, can solve problems such as narrow band gaps, achieve the effects of reducing the impact of device performance, improving luminous efficiency, and increasing carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

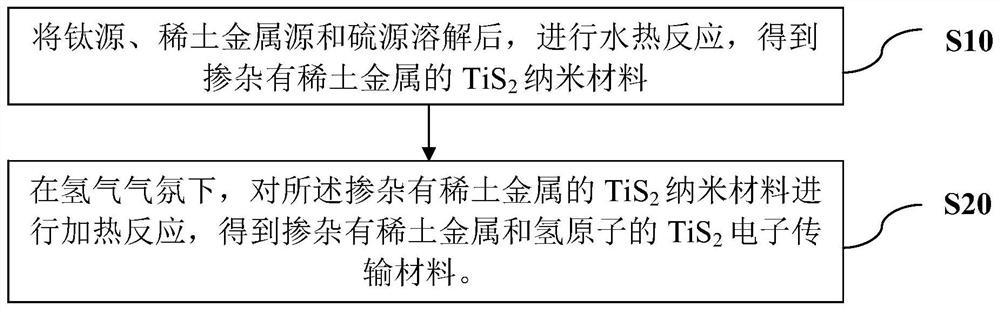

[0027] The first aspect of the embodiment of the present application provides a method for preparing an electron transport material, comprising the following steps:

[0028] S10. After dissolving titanium source, rare earth metal source and sulfur source, perform hydrothermal reaction to obtain TiS doped with rare earth metal 2 nanomaterials;

[0029] S20. In a hydrogen atmosphere, the TiS doped with rare earth metals 2 Nanomaterials undergo a heating reaction to obtain TiS doped with rare earth metals and hydrogen atoms 2 Electron transport materials.

[0030] The preparation method of the electron transport material provided by the first aspect of the present application comprises mixing and dissolving titanium source, rare earth metal source and sulfur source in water, and obtaining TiS doped with rare earth metal through hydrothermal reaction. 2 Nanomaterials; under hydrogen atmosphere, TiS doped with rare earth metals 2 Nanomaterial undergoes heating reaction to repla...

Embodiment 1

[0077] An electron transport material, comprising the following preparation steps:

[0078] ①First, add 1g of titanium sulfate and an appropriate amount of cerium sulfate into 50ml of water to form a solution with a total concentration of 0.5M, wherein the molar ratio of titanium: cerium is 1:0.1, and then add an appropriate amount of sodium sulfide (molar ratio, S 2- :M x+ =2.2:1). After being dispersed, it was transferred to a hydrothermal reaction tank, reacted at 200°C for 24 hours, and cooled and washed (washed twice with water and once with absolute ethanol). Then dried at 50 °C to obtain Ce / TiS 2 nanomaterials.

[0079] ②Add 1g Ce / TiS 2 The powder is spread on a boat-shaped crucible, placed in a muffle furnace and continuously fed with argon. After exhausting for 20 minutes, raise the temperature of the muffle furnace to 300°C, switch the argon gas to a hydrogen-containing argon mixed gas (5% hydrogen + 95% argon), keep the flow rate of the mixed gas at 80-100ml / mi...

Embodiment 2

[0081] An electron transport material, comprising the following preparation steps:

[0082] ①First, add 1g of titanium nitrate and appropriate amount of terbium nitrate into 50ml of water to form a solution with a total concentration of 0.5M, wherein the molar ratio of titanium: terbium is 1:0.2, and then add an appropriate amount of potassium sulfide (molar ratio, S 2- :M x+ =2.5:1). After being dispersed, it was transferred to a hydrothermal reaction kettle, reacted at 220°C for 24 hours, and cooled and washed (washed twice with water and once with absolute ethanol). Then dried at 50 °C to obtain Tb / TiS 2 nanomaterials.

[0083] ② Add 1g Tb / TiS 2 The powder is spread on a boat-shaped crucible, placed in a muffle furnace and continuously fed with argon. After exhausting for 20 minutes, raise the temperature of the muffle furnace to 300°C, switch the argon gas to a hydrogen-nitrogen mixed gas (8% hydrogen + 92% nitrogen), keep the flow rate of the mixed gas at 60-80ml / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com