Anti-pollution antibacterial PTFE oil-water separation membrane and preparation method thereof

An oil-water separation membrane, anti-pollution technology, applied in semi-permeable membrane separation, chemical instruments and methods, osmotic/dialysis water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Synthesis of acrylamide thiolactone:

[0045] A mixed solution of DL-homocysteine thiolactone hydrochloride (7.68g, 50mmol), 200mL ethyl acetate and water (1:1 by volume) was added to the three-necked flask, and placed in an ice-water bath Then add sodium bicarbonate (18.9g, 225mmol) and stir for 30min; then add acryloyl chloride (10.1g, 110mmol) dropwise and stir for 30min; remove the ice-water bath, react at room temperature for 12h, and use the obtained product 200mL of 1mol / L sodium chloride solution was washed and extracted three times with ethyl acetate (200mL / time), and the organic layer was taken each time; finally, the extracted organic layer liquid was dried with anhydrous sodium sulfate, rotary evaporated, and the obtained crude The product was crystallized and purified in dichloromethane to obtain acrylamide thiolactone (TlaAm) as a white solid;

[0046] (2) Synthesis of P (DMAEMA-co-TlaAm) copolymer:

[0047] Dimethylaminoethyl methacrylate (DMAEMA)...

Embodiment 2

[0056] The copolymer P (DMAEMA-co-TlaAm) prepared based on embodiment 1 prepares antifouling and antibacterial oil-water separation membrane, and its specific preparation steps are as follows:

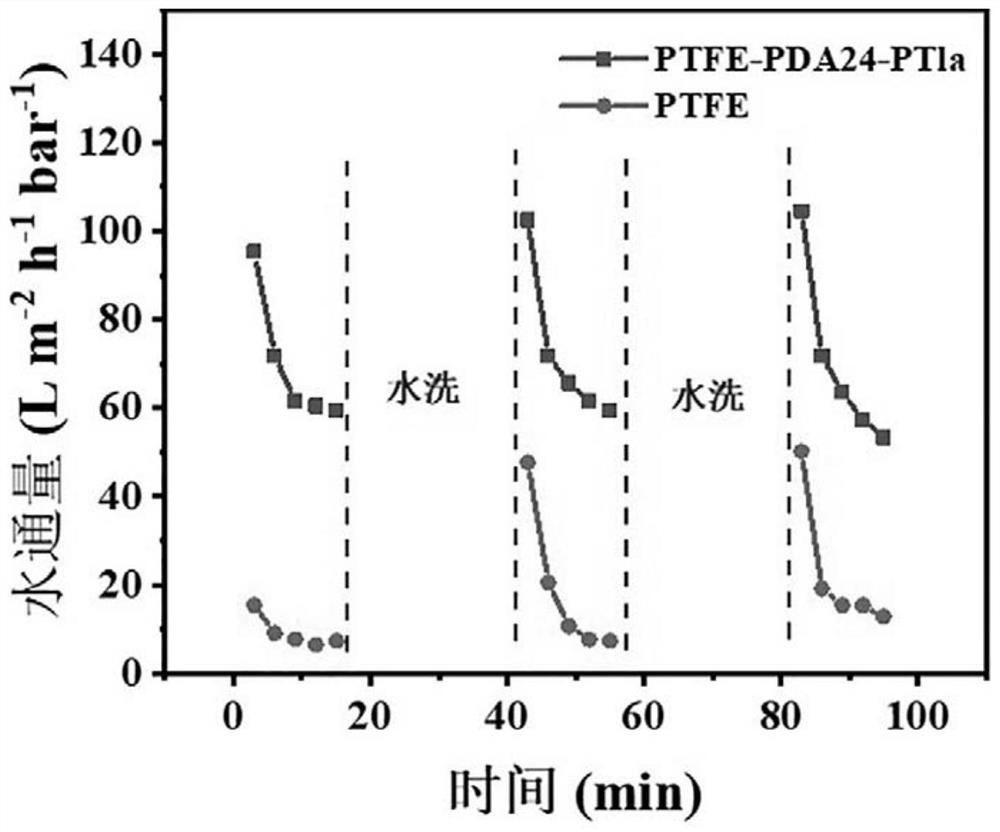

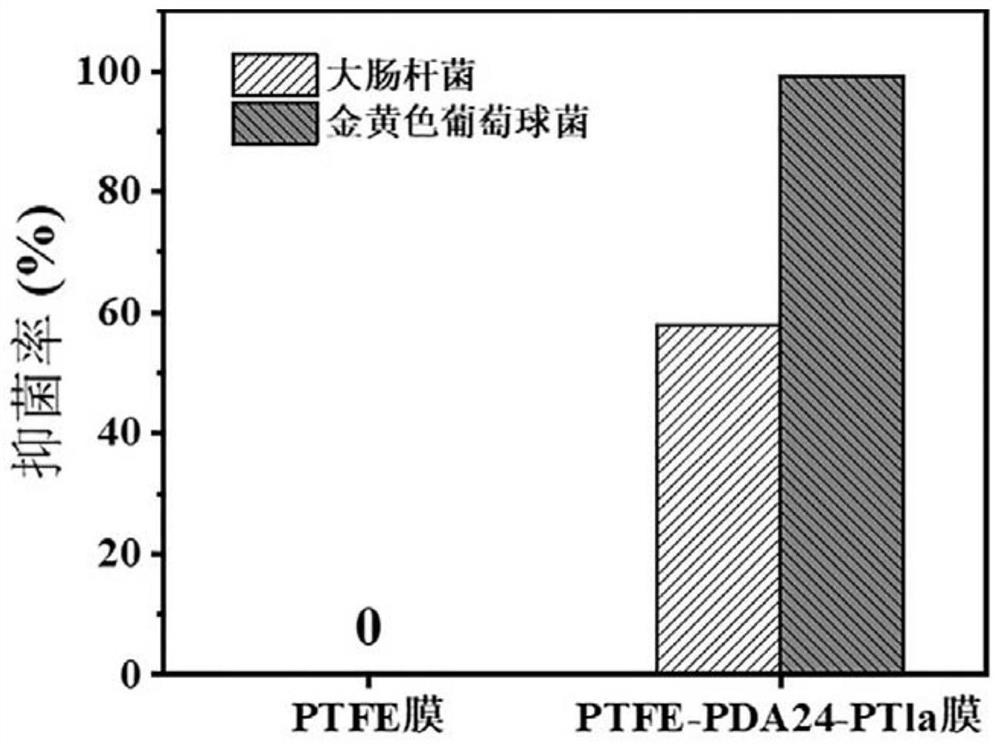

[0057] Step 1, the polytetrafluoroethylene membrane was ultrasonically cleaned with ethanol and acetone respectively for 15 minutes; then immersed in a solution of 2 g / L dopamine hydrochloride / Tris (pH=8.5, 50 mM) and placed on a shaker at room temperature Shake at a constant speed for 4 hours; then, rinse with deionized water three times repeatedly, and place on a shaker in pure water for 10 minutes; take it out, and dry it in a vacuum at 40°C to constant weight, and the deposited film is PTFE-PDA- 4;

[0058] Step 2, glucosamine (0.0216g, 0.12mmol) and copolymer P (DMAEMA-co-TlaAm) (1.446g, 0.06mmol) are dissolved in the Tris solution of 50mL, then the deposited film prepared by step 1 is immersed in The solution was placed on a shaker and shaken at room temperature for 24 hours; th...

Embodiment 3

[0061] The copolymer P (DMAEMA-co-TlaAm) prepared based on embodiment 1 prepares antifouling and antibacterial oil-water separation membrane, and its specific preparation steps are as follows:

[0062] Step 1, the polytetrafluoroethylene membrane was ultrasonically cleaned with ethanol and acetone respectively for 15 minutes; then immersed in a solution of 2 g / L dopamine hydrochloride / Tris (pH=8.5, 50 mM) and placed on a shaker at room temperature Shake at a constant speed for 12 hours; then, rinse with deionized water three times repeatedly, and place on a shaker in pure water for 10 minutes; take it out, and dry it in a vacuum at 40°C to constant weight, and the deposited film is PTFE-PDA- 12;

[0063] Step 2, glucosamine (0.0216g, 0.12mmol) and copolymer P (DMAEMA-co-TlaAm) (1.446g, 0.06mmol) are dissolved in the Tris solution of 50mL, then the deposited film prepared by step 1 is immersed in The solution was placed on a shaker and shaken at room temperature for 24 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com