Blended low-thermal-conductivity film containing nanoscale low-thermal-conductivity material and high polymer as well as preparation method and application of blended low-thermal-conductivity film

A high-polymer film, low thermal conductivity technology, applied in chemical instruments and methods, film, film technology and other directions, can solve the problems of increasing the complexity of film components and equipment, high cost of aerogel materials, limited improvement, etc. The effect of increasing flux and heat utilization, improving structural performance, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

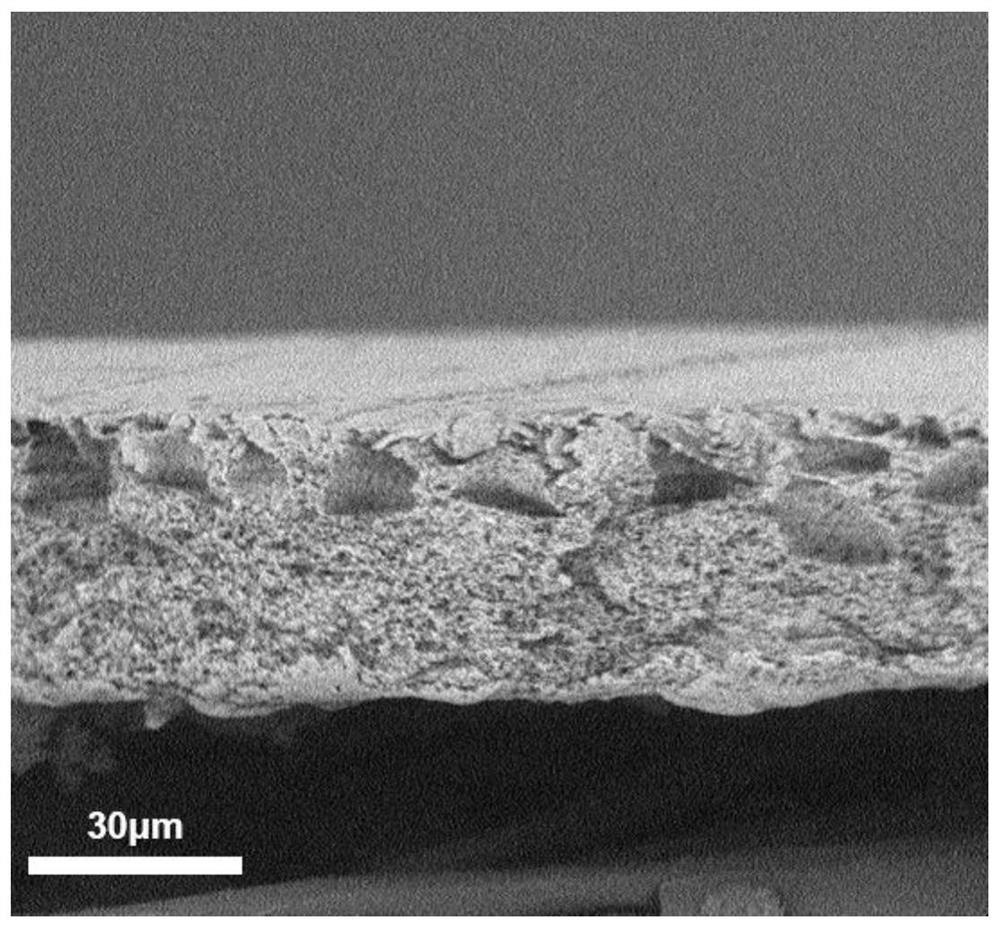

Embodiment 1

[0034] (1) The mass fraction of polyvinylidene fluoride is 12wt.%, the mass fraction of nano aluminum silicate is 2wt.%, solvent DMAC82wt.%, additive LiCl 3wt.%, acetone 1wt.%;

[0035] (2) Add the mixed raw materials weighed in step (1) into the reactor, and stir electrically for about 12 hours in a constant temperature water bath at 60°C to form a uniform and stable casting solution, which is left to stand at room temperature for defoaming for 12 hours to obtain a homogeneous casting solution. Membrane fluid;

[0036] (3) Scrape the liquid film of 150 μm on the non-woven fabric with a scraper for the casting solution obtained in (2), first immerse in the gel bath ethanol aqueous solution for 5 minutes, and rinse it with deionized water after the phase separation is completed and taken out;

[0037](4) Transfer the film prepared in step (3) into deionized water and soak for 24 hours, so that the solvent is completely extracted, and the polyvinylidene fluoride / nano-aluminum si...

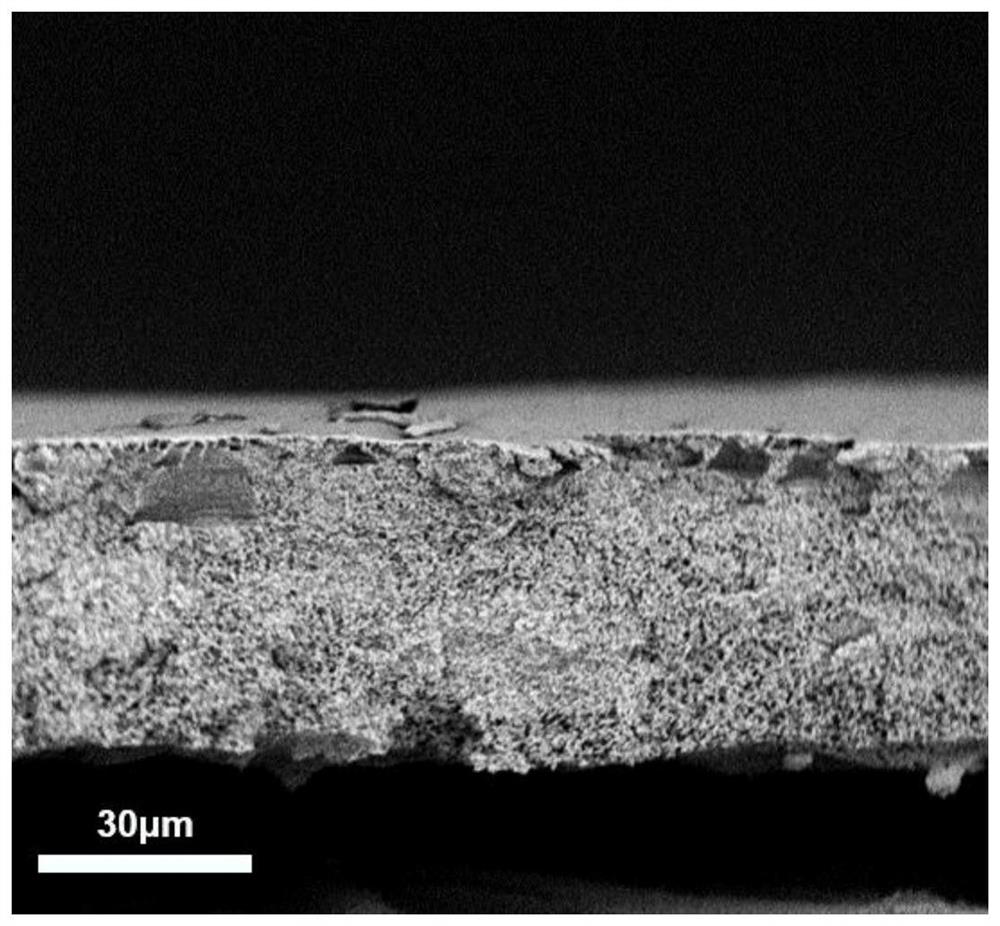

Embodiment 2

[0040] (1) The mass fraction of polyvinylidene fluoride is 12wt.%, the mass fraction of nano aluminum silicate is 4wt.%, solvent DMAC80wt.%, additive LiCl 3wt.%, acetone 1wt.%;

[0041] (2) Add the mixed raw materials weighed in step (1) into the reactor, and stir electrically for about 12 hours in a constant temperature water bath at 60°C to form a uniform and stable casting solution, which is left to stand at room temperature for defoaming for 12 hours to obtain a homogeneous casting solution. Membrane fluid;

[0042] (3) Scrape the liquid film of 150 μm on the non-woven fabric with a scraper for the casting solution obtained in (2), first immerse in the gel bath ethanol aqueous solution for 5 minutes, and rinse it with deionized water after the phase separation is completed and taken out;

[0043] (4) Transfer the film prepared in step (3) into deionized water and soak for 24 hours, so that the solvent is completely extracted, and the polyvinylidene fluoride / nano-aluminum s...

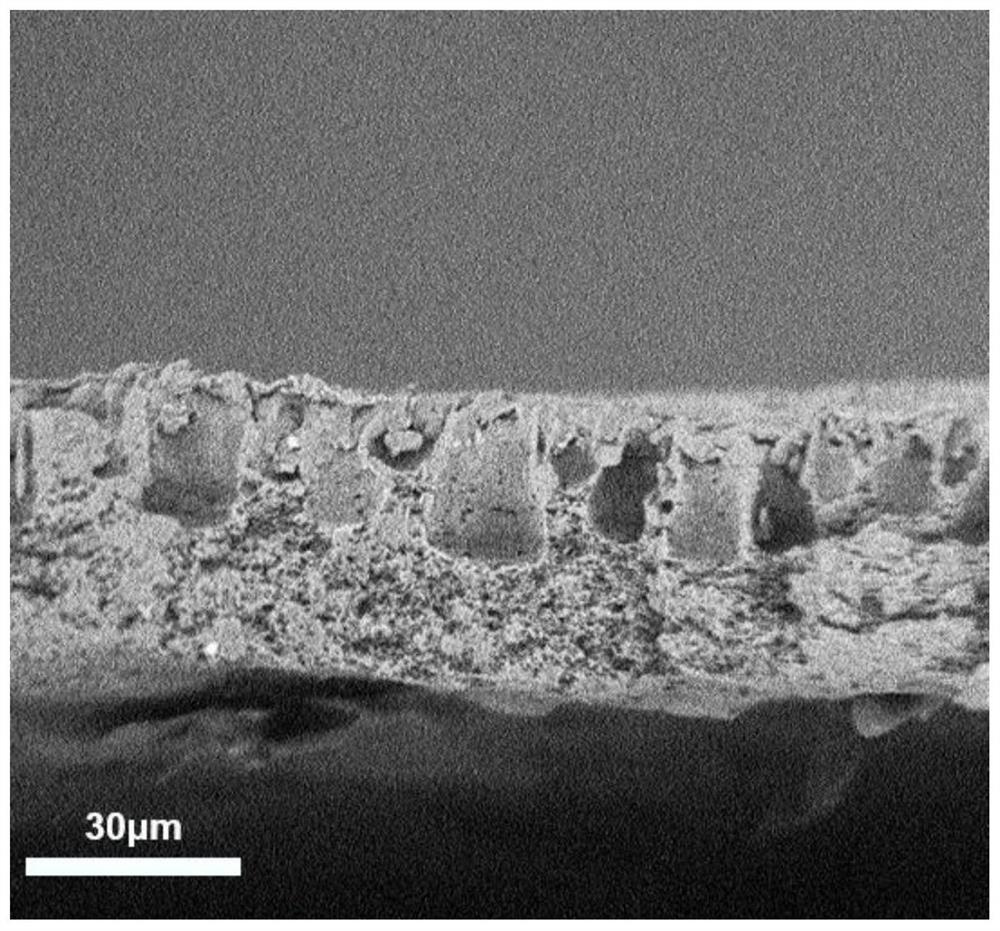

Embodiment 3

[0046] (1) The mass fraction of polyvinylidene fluoride is 12wt.%, the mass fraction of nano polystyrene rubber powder particles is 2wt.%, solvent DMAC 82wt.%, additive LiCl 3wt.%, acetone 1wt.%;

[0047] (2) Add the mixed raw materials weighed in step (1) into the reactor, and stir electrically for about 12 hours in a constant temperature water bath at 60°C to form a uniform and stable casting solution, which is left to stand at room temperature for defoaming for 12 hours to obtain a homogeneous casting solution. Membrane fluid;

[0048] (3) Scrape the liquid film of 150 μm on the non-woven fabric with a scraper for the casting solution obtained in (2), first immerse in the gel bath ethanol aqueous solution for 5 minutes, and rinse it with deionized water after the phase separation is completed and taken out;

[0049] (4) Transfer the film prepared in step (3) into deionized water and soak for 24 hours, so that the solvent is completely extracted, and the polyvinylidene fluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com