Porous granular molecular sieve VOCs adsorbent and preparation method thereof

A technology of porous particles and molecular sieves, applied in molecular sieve catalysts, separation methods, catalyst activation/preparation, etc., can solve problems such as inhomogeneous properties of adsorption functional groups, reduction of adsorption capacity, and attenuation of VOCs adsorption capacity, and achieve enhanced repression and binding effects, Avoid structural stress concentration and increase the effect of adsorption surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

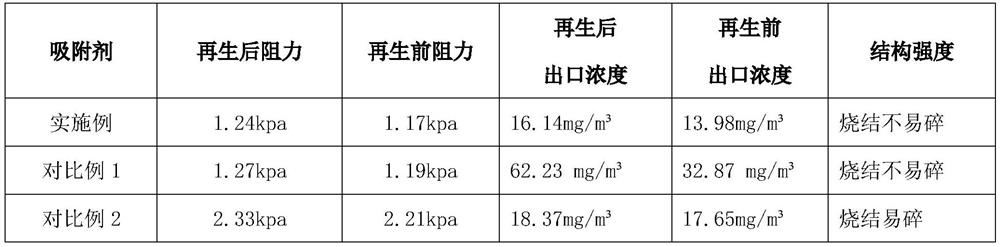

Examples

specific Embodiment approach

[0031] The porous granular molecular sieve VOCs adsorbent is characterized in that the following raw materials are used: according to the parts by mass:

[0032] HY molecular sieve powder: 50-55 parts; aluminum sol: 5-10 parts; water: 25-30 parts; kaolin: 5-10 parts; pore-forming agent: 1-3 parts; pore-forming agent: 1-3 parts ;

[0033] The VOCs adsorbent includes a channel for transporting the adsorbed gas, and the channel is formed by an auxiliary agent and a pore-forming agent auxiliary agent, and the auxiliary agent and the pore-forming agent aid leave a channel for transporting the adsorbed gas after the thermal decomposition process.

[0034] The pore-forming aid is polyvinyl alcohol fiber; the pore-forming agent is ammonium bicarbonate or ammonium carbonate.

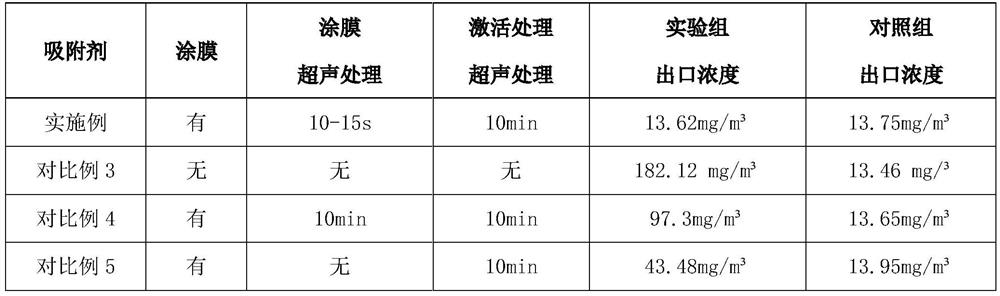

[0035] The VOCs adsorbent is coated with a composite membrane, and the composite membrane is a composite membrane of pullulan and sodium alginate.

[0036] The VOCs adsorbent needs to be soaked in water and tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com