Copper-based brazing filler metal capable of accurately controlling using amount of brazing flux and good in brazing seam protection effect

A copper-based solder, precise control technology, applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problems of increasing difficulties, hindering the plastic deformation of solder, polluting the environment, etc., and achieve good removal , promote fluidity, and have a large active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

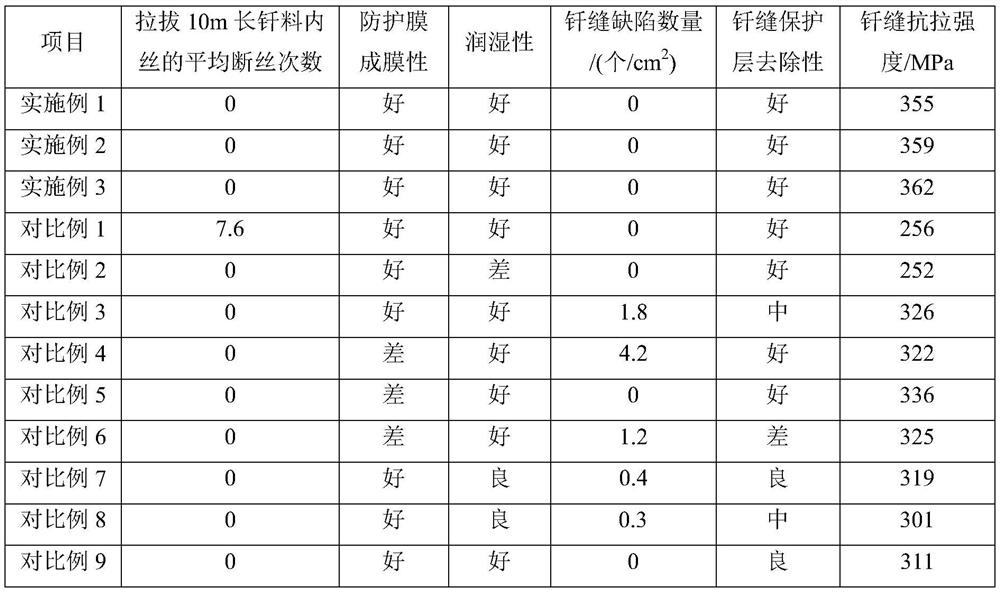

Examples

Embodiment 1

[0058] Prepare the copper-based brazing material described in the present invention that can accurately control the amount of flux and has a good protective effect on the brazing seam, including a copper-based brazing material inner wire and a protective film, and the protective film is coated on the outside of the copper-based solder inner wire, The chemical composition of the protective film includes by mass percentage: 10% of zinc phosphide powder treated with coupling agent, 5% of kyanite powder treated with coupling agent, 3% of glass fiber treated with coupling agent, 2.5% of nano silicon dioxide powder processed with coupling agent, 10% of boric anhydride powder processed with coupling agent, 20% of potassium fluoroborate powder processed with coupling agent, 5.5% of curing agent, and the balance is epoxy resin.

[0059] The cross-section of the copper-based solder inner wire in the vertical length direction is circular, with a diameter of 1.6 mm.

[0060] The chemical...

Embodiment 2

[0069] Prepare the copper-based brazing material described in the present invention that can accurately control the amount of flux and has a good protective effect on the brazing seam, including a copper-based brazing material inner wire and a protective film, and the protective film is coated on the outside of the copper-based solder inner wire, The chemical composition of the protective film includes: 11% of zinc phosphide powder treated with coupling agent, 6% of kyanite powder treated with coupling agent, 4% of glass fiber treated with coupling agent, 3% of nano silicon dioxide powder processed with coupling agent, 11% of boric anhydride powder processed with coupling agent, 23% of potassium fluoroborate powder processed with coupling agent, 6% of curing agent, and the balance is epoxy resin.

[0070] The cross-section of the copper-based solder inner wire in the vertical length direction is circular, with a diameter of 3.0 mm.

[0071] The chemical composition of the inn...

Embodiment 3

[0080] Prepare the copper-based brazing material described in the present invention that can accurately control the amount of flux and has a good protective effect on the brazing seam, including a copper-based brazing material inner wire and a protective film, and the protective film is coated on the outside of the copper-based solder inner wire, The chemical composition of the protective film includes: 12% of zinc phosphide powder treated with coupling agent, 7% of kyanite powder treated with coupling agent, 5% of glass fiber treated with coupling agent, 3.5% of nano silicon dioxide powder processed with coupling agent, 12% of boric anhydride powder processed with coupling agent, 25% of potassium fluoroborate powder processed with coupling agent, 6.5% of curing agent, and the balance is epoxy resin.

[0081] The cross-section in the vertical direction of the copper-based solder inner wire is elliptical, with a major axis length of 2.5 mm and a minor axis length of 1.75 mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com