Multicolor antibacterial film layer and preparation method as well as application thereof

An antibacterial film and multi-color technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of insufficient coverage, unfavorable selection range of antibacterial film technology, strong wrapping ability, etc., to achieve The effect of reducing remaining parts, rich color selection, and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

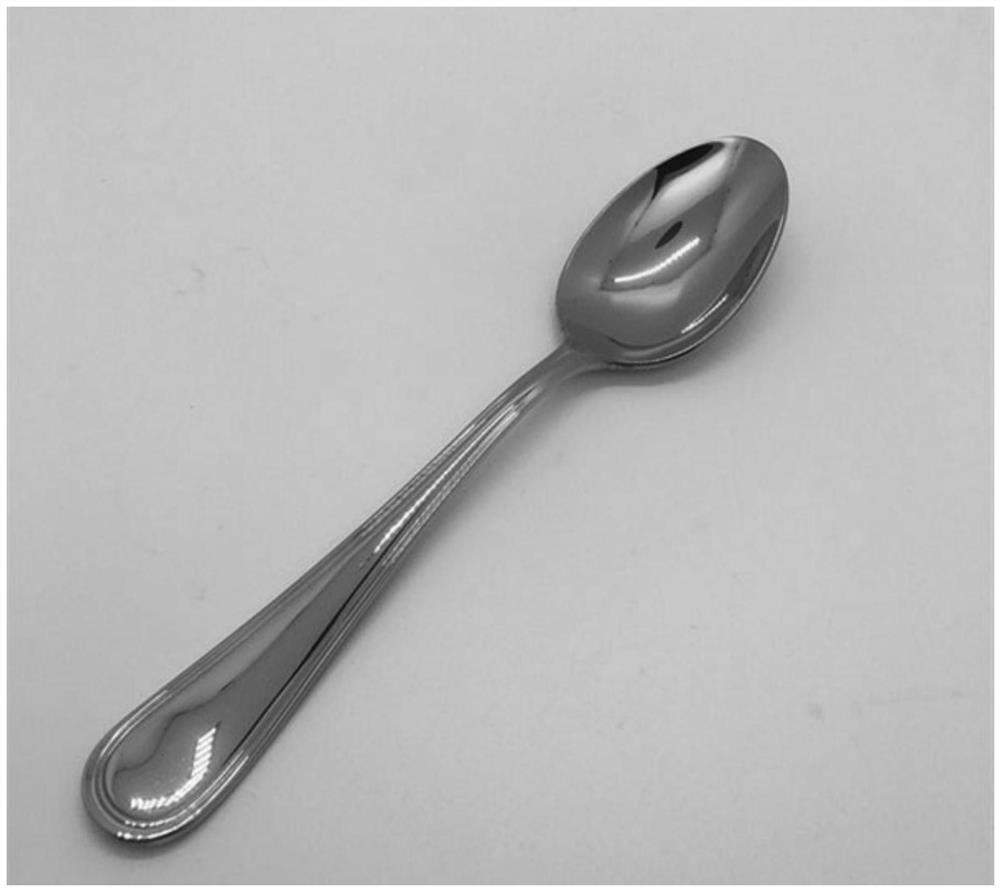

Image

Examples

preparation example Construction

[0060] A kind of preparation method of multi-color antibacterial film layer of the embodiment of the present invention, comprises the following steps:

[0061] (1) Use an automatic cleaning machine to clean the surface of the substrate, so that the surface of the substrate can reach a clean state without dirt;

[0062] The invention does not need to carry out chemical processes such as electroplating nickel on the substrate, and can be directly put into the coating equipment for coating treatment after normal cleaning, the process is simple, and it is environmentally friendly and pollution-free.

[0063] (2) Put the substrate treated in step (1) into the vacuum ion coating equipment for vacuuming and preheating, and perform surface activation treatment; the substrate is subjected to surface activation treatment, which can make the ions of the substrate surface substances enter an active state, Thus, the ion plating step in the subsequent step can form a film faster, shorten th...

Embodiment 1

[0084] A method for preparing a metal primary color antibacterial film layer, comprising the following steps:

[0085] (1) Use an automatic cleaning machine to clean the surface of the substrate, so that the surface of the substrate can reach a clean state without dirt;

[0086] (2) Putting the substrate processed through step (1) into a vacuum ion coating device for vacuuming and preheating, and performing surface activation treatment;

[0087] (3) continue in the same vacuum ion coating equipment, carry out titanium coating to the substrate processed through step (2):

[0088] A. When the vacuum reaches 1.8~2.8x10 -1 At Pa, argon gas is introduced, and the flow rate is controlled at 220-380cm 3 / min;

[0089] B. Set the rotating speed of the turret to 45~65, and the range of the grating to change from 40 to 50 degrees;

[0090] C. Introduce nitrogen, the flow rate is controlled at 280 ~ 350cm 3 / min;

[0091] D. Turn on the weak ion power supply, turn on the titanium t...

Embodiment 2

[0100] A preparation method of a golden antibacterial film layer, comprising the following steps:

[0101] (1) Use an automatic cleaning machine to clean the surface of the substrate, so that the surface of the substrate can reach a clean state without dirt;

[0102] (2) Putting the substrate processed through step (1) into a vacuum ion coating device for vacuuming and preheating, and performing surface activation treatment;

[0103] (3) continue in the same vacuum ion coating equipment, carry out titanium coating to the substrate processed through step (2):

[0104] A. When the vacuum reaches 1.8~2.8x10 -1 At Pa, argon gas is introduced, and the flow rate is 220-380cm 3 / min;

[0105] B. Set the rotating speed of the turret to 45~65, and the range of the grating to change from 40 to 50 degrees;

[0106] C. Introduce nitrogen, the flow rate is controlled at 280 ~ 350cm 3 / min;

[0107] D. Turn on the weak ion power supply, turn on the titanium target for ion coating, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com