Composite electrochromic material as well as preparation method and application thereof

A technology of electrochromic materials and raw materials, applied in textiles and papermaking, conjugated synthetic polymer artificial filaments, filament/wire molding, etc., can solve the problems of fatigue resistance, electrochromic function failure, electrochromic materials Easy to damage and other problems, to achieve the effect of good fatigue resistance, reversible color change, and stable color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

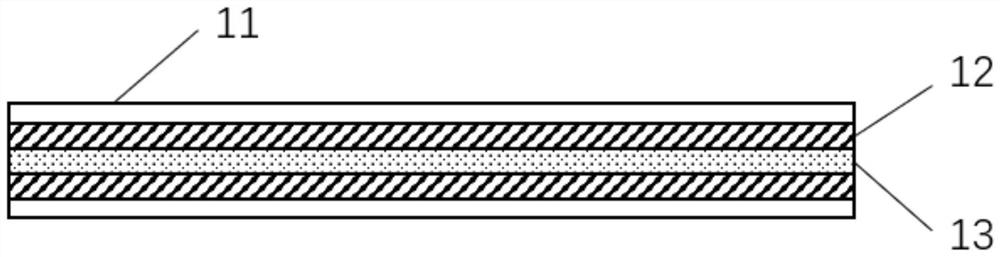

[0047] This example provides a composite electrochromic material, such as figure 1 As shown, it consists of a core layer 11, a skin layer 12 with electrochromic function, and a light-transmitting flexible polymer material protective layer 13, which are sequentially arranged from the inside to the outside. The core layer material includes a fluid conductive mixture, which is conductive The mixture includes liquid metal and carboxylated carbon nanotubes, and the mass ratio of carboxylated carbon nanotubes to liquid metal is 3:100; among them, the liquid metal is composed of gallium, indium and tin with a mass ratio of 68.5:21.5:10 .

[0048] The raw material of the skin layer with electrochromic function is a composite material obtained by mixing polyaniline and polyvinyl alcohol with a mass ratio of 2:1.

[0049] The raw material of the light-transmitting flexible polymer material protective layer is polyolefin elastomer, which is purchased from The Dow Chemical Company (Dow, ...

Embodiment 2

[0057] This example provides a composite electrochromic material, which consists of a core layer arranged in sequence from the inside out, a skin layer with electrochromic function, and a protective layer of flexible polymer material capable of light transmission. The conductive mixture includes liquid metal and carboxylated carbon nanotubes, and the mass ratio of carboxylated carbon nanotubes to liquid metal is 3:100; wherein, the liquid metal is composed of gallium, indium and Tin is composed of three metals.

[0058] The raw material of the skin layer with the electrochromic function is a composite material obtained by mixing polyaniline and polyvinyl alcohol with a mass ratio of 1:1.

[0059] The raw material of the light-transmitting flexible polymer material protective layer is polyolefin elastomer, which is purchased from The Dow Chemical Company (Dow, USA) and has a melt index of 30 g / 10 min.

[0060] The preparation method of composite electrochromic material compris...

Embodiment 3

[0067] This example provides a composite electrochromic material, which consists of a core layer arranged in sequence from the inside out, a skin layer with electrochromic function, and a protective layer of flexible polymer material capable of light transmission. The conductive mixture includes liquid metal and carboxylated carbon nanotubes, and the mass ratio of carboxylated carbon nanotubes to liquid metal is 5:100; wherein, the liquid metal is composed of gallium, indium and Tin is composed of three metals.

[0068] The raw material of the skin layer with the electrochromic function is a composite material obtained by mixing polyaniline and polyvinyl alcohol with a mass ratio of 1:1.

[0069] The raw material of the light-transmitting flexible polymer material protective layer is polyolefin elastomer, which is purchased from The Dow Chemical Company (Dow, USA) and has a melt index of 30 g / 10 min.

[0070] The preparation method of composite electrochromic material compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com