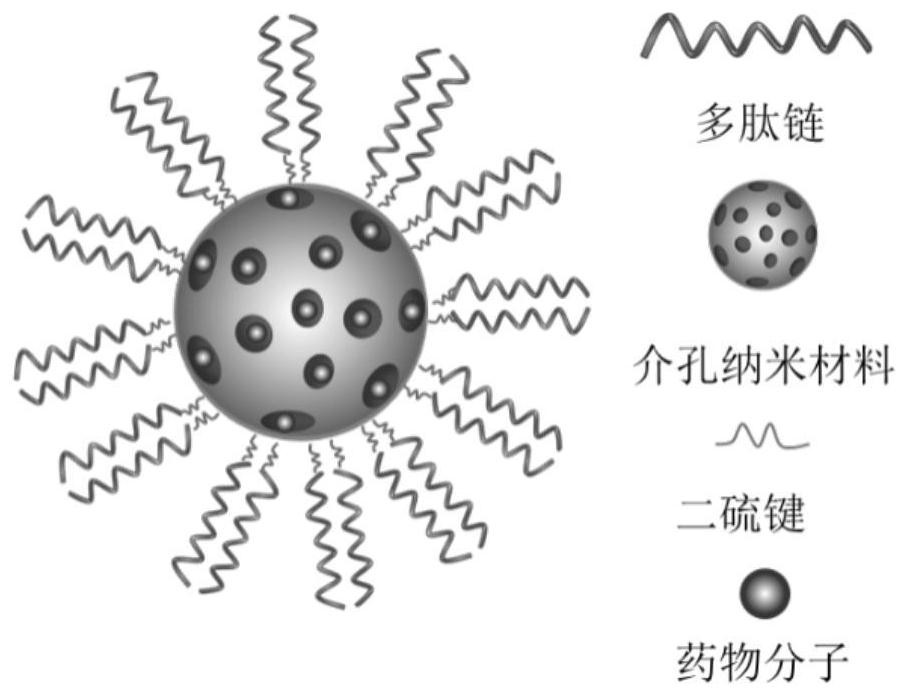

Temperature-sensitive polypeptide encapsulated mesoporous silica intelligent drug carrier and preparation thereof

A mesoporous silica, temperature-sensitive technology, applied in the field of physical chemistry, can solve the problems of restricted application, cytotoxicity and refractory degradation, and achieve good biocompatibility and low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

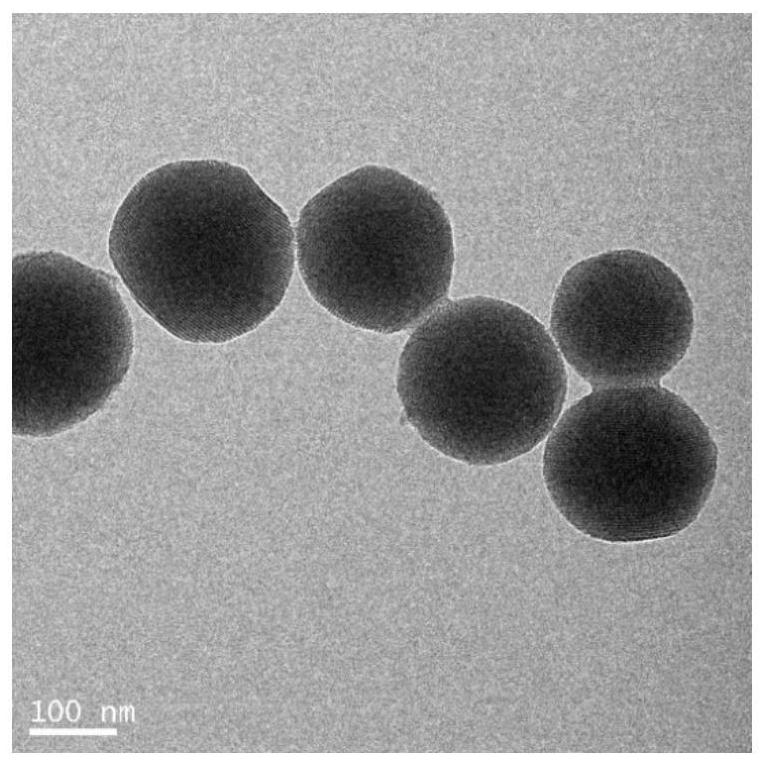

[0038] Example 1 Preparation of mesoporous silica nano drug carrier for polypeptide encapsulation based on Lpep.

[0039] (1) Preparation of mesoporous silica (MSN)

[0040] Prepare mesoporous silica (MSN), adopt sol-gel method, weigh 0.5g CTAB, place in a 500mL round bottom flask, add 240mL ultrapure water, ultrasonically dissolve for 20min, add dropwise 1.75mL of 2M NaOH solution, Raise the temperature to 80°C, stir for 30 minutes, use a constant flow pump to add 2.5mL of TEOS dropwise, set the dropping time to 12 minutes, then increase the stirring speed to 500r / min, react at 80°C for 2h, and then let it stand until room temperature. After standing and aging, centrifuge with a centrifuge, discard the supernatant, and repeatedly wash with ethanol and deionized water until the supernatant is neutral. A white product was obtained, which was transferred to an 80° C. vacuum oven for drying for 24 h.

[0041] (2) Synthesis of MSN-SH

[0042]Weigh 100mg of the MSN prepared in ...

Embodiment 2

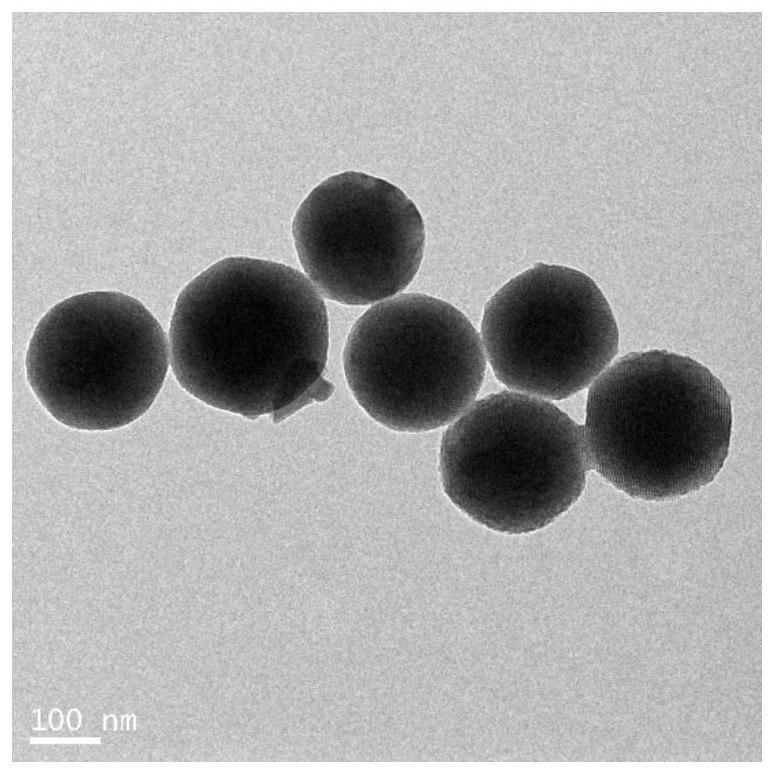

[0049] Example 2 Preparation of nano drug carrier encapsulated based on Spep polypeptide

[0050] (1) Preparation of mesoporous silica (MSN)

[0051] Prepare mesoporous silica (MSN), adopt sol-gel method, weigh 0.5g CTAB, place in a 500mL round bottom flask, add 240mL ultrapure water, ultrasonically dissolve for 20min, add dropwise 1.75mL of 2M NaOH solution, Raise the temperature to 80°C, stir for 30 minutes, use a constant flow pump to add 2.5mL of TEOS dropwise, set the dropping time to 12 minutes, then increase the stirring speed to 500r / min, react at 80°C for 2h, and then let it stand until room temperature. After standing and aging, centrifuge with a centrifuge, discard the supernatant, and repeatedly wash with ethanol and deionized water until the supernatant is neutral. A white product was obtained, which was transferred to an 80° C. vacuum oven for drying for 24 h.

[0052] (2) Synthesis of MSN-SH

[0053] Weigh 200 mg of the MSN prepared in the above step 1), put...

Embodiment 3

[0060] Example 3 Research on Drug Controlled Release of Mesoporous Silica Drug Carrier Blocked by Polypeptide.

[0061] (1) The temperature-sensitive performance test of the polypeptide, the secondary structure of the polypeptide Lpep and Spep was tested by circular dichroism chromatography, and the aqueous solution of 40 μM Lpep and the aqueous solution of 40 μM Spep were respectively prepared. The detection wavelength range was 180-260nm, and the temperature was set at 25°C -70°C, the heating rate is 2°C / time. Figure 4(A) and 4(B) The changes of the secondary structure of Lpep and Spep with temperature are given respectively, and the change of the secondary structure with temperature can be seen. The phase transition temperature is given by the global 3 software, and the phase transition temperature of Lpep: 47.1±5.2°C , the phase transition temperature of Spep: 43.4±4.8°C.

[0062] (2) Drug controlled release test.

[0063] In order to study the release behavior of this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com