Method for preparing nickel ferrite nano-material from nickel-iron-containing electroplating wastewater and applications

A technology of electroplating wastewater and nanomaterials, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor performance of carbon dioxide, etc., and achieve the effects of easy recycling, significant environmental protection and economic benefits, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040](1) Transfer the metal ions in the electroplating wastewater to the organic phase: take 20ml of 0.05mol / L nickel-iron-containing electroplating wastewater, add 10ml of ethanol, 20ml of n-hexane, and 2mmol of oleylamine. The heating and stirring system was maintained at 70°C for 1h. The metal ions are transferred from the lower aqueous phase to the upper organic solution phase.

[0041] (2) Cool the system in step (1) to room temperature and transfer it to a reaction kettle, add 10ml of NaOH solution with 5mmol, 10mmol, and 15mmol of substances, respectively, heat to 180°C, and react at constant temperature for 24h. After the reaction is finished, the solution system is separated into layers, the lower aqueous phase is removed, the nickel ferrite in the organic phase is centrifuged, washed and dried to obtain the nickel ferrite nanomaterial.

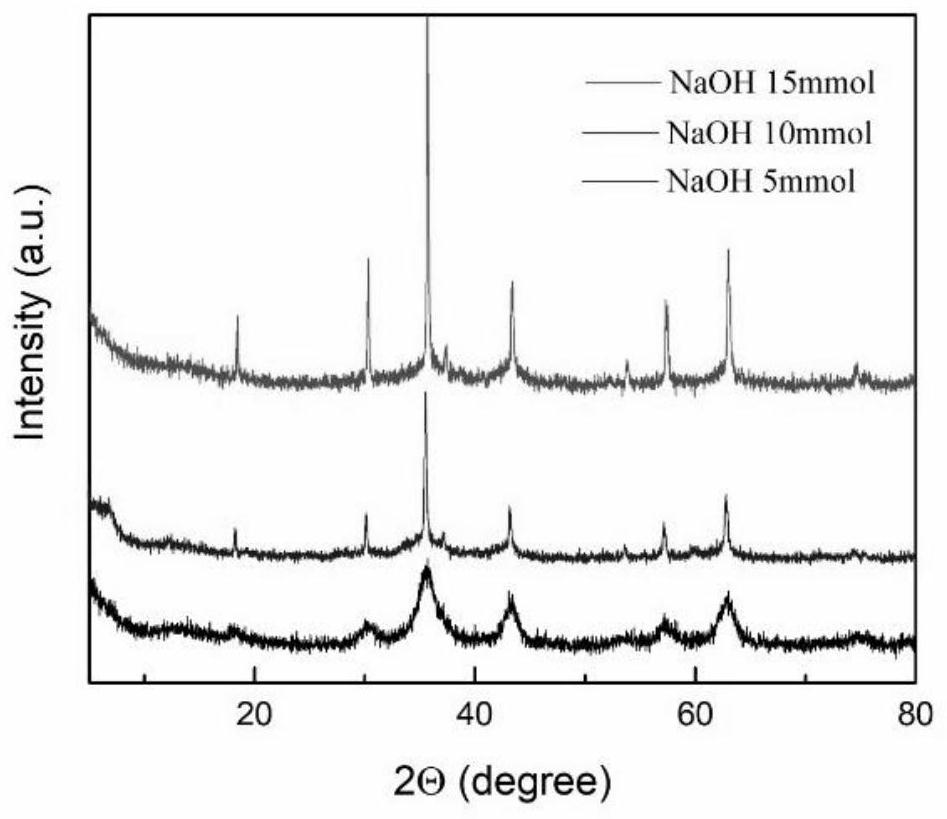

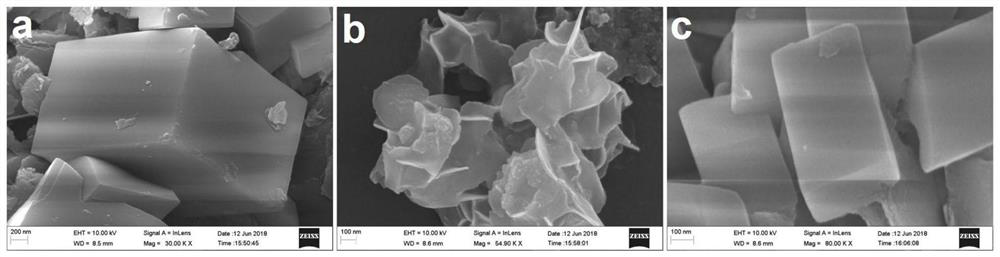

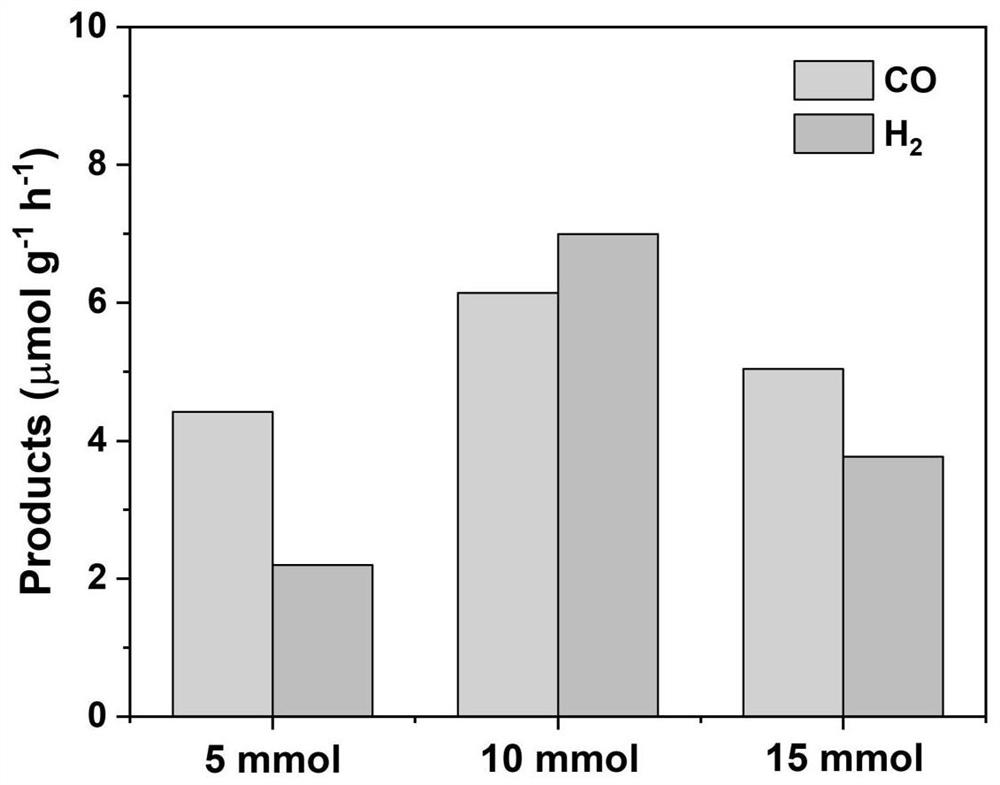

[0042] The XRD spectrum of the nickel ferrite synthesized in this embodiment under different alkali addition conditions is as fol...

Embodiment 2

[0044] (1) Transfer the metal ions in the electroplating wastewater to the organic phase: take 20ml of 0.05mol / L ferronickel-containing electroplating wastewater, add 10ml of ethanol, 20ml of n-hexane, and 2mmol of sodium dodecylbenzenesulfonate. The heating and stirring system was maintained at 70°C for 1h. The metal ions are transferred from the lower aqueous phase to the upper organic solution phase.

[0045] (2) Cool the system in step (1) to room temperature and transfer it to a reaction kettle, add 10ml of NaOH solution with a substance amount of 10mmol, heat to 180°C, and react at a constant temperature for 24h. After the reaction is finished, the solution system is separated into layers, the lower aqueous phase is removed, the nickel ferrite in the organic phase is centrifuged, washed, and dried to obtain flower-shaped nickel ferrite nanomaterials.

Embodiment 3

[0047] (1) Transfer the metal ions in the electroplating wastewater to the organic phase: take 20ml of 0.05mol / L nickel-iron-containing electroplating wastewater, add 10ml of ethanol, 20ml of n-hexane, and 2mmol of polyacrylamide. The heating and stirring system was maintained at 70°C for 1h. The metal ions are transferred from the lower aqueous phase to the upper organic solution phase.

[0048] (2) Cool the system in step (1) to room temperature and transfer it to a reaction kettle, add 10ml of NaOH solution with a substance amount of 10mmol, heat to 180°C, and react at a constant temperature for 24h. After the reaction is finished, the solution system is separated into layers, the lower aqueous phase is removed, the nickel ferrite in the organic phase is centrifuged, washed, and dried to obtain flower-shaped nickel ferrite nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com