Application of bis(fluorosulfonyl)imide as catalyst

The technology of bisfluorosulfonimide and catalyst is applied in the application field of bisfluorosulfonimide as a catalyst, which can solve the problems of narrow application field of bisfluorosulfonimide, and achieves strong substrate adaptability and atom economy. High performance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0269]

[0270] Add 10 g of potassium bisfluorosulfonimide (45.6 mmol) and 10 g of 98% concentrated sulfuric acid (100 mmol) into the autoclave, feed 60 g of sulfur dioxide at -70°C, slowly rise to room temperature, react for half an hour, and a white solid appears Generate, then slowly release sulfur dioxide gas, add 50ml of dichloromethane, filter, the solid is washed with 50ml of dichloromethane, the filtrate is spin-dried, and distilled under reduced pressure to collect 85 ° C / 20mm Hg fractions to obtain 7.7 g of difluorosulfonimide ( 42.5 mmol), colorless liquid, yield 93%.

[0271] 19 F NMR (dichloromethane as solvent, fluorotrichloromethane as internal standard): +57.3.

preparation Embodiment 2

[0273]

[0274] Add 10g of sodium bisfluorosulfonimide (49.26mmol) and 10g of 98% concentrated sulfuric acid (100mmol) into the autoclave, feed 60g of sulfur dioxide at -70°C, slowly rise to room temperature, react for half an hour, and there is a white solid Generate, then slowly release sulfur dioxide gas, add 50ml of dichloromethane, filter, wash the solid with 50ml of dichloromethane, spin the filtrate, distill under reduced pressure, collect 85 ° C / 20mm Hg fractions, and obtain 8.1 g of difluorosulfonimide ( 44.75 mmol), colorless liquid, yield 91%.

[0275] 19 F NMR (dichloromethane as solvent, fluorotrichloromethane as internal standard): +57.3.

Embodiment 1

[0277]

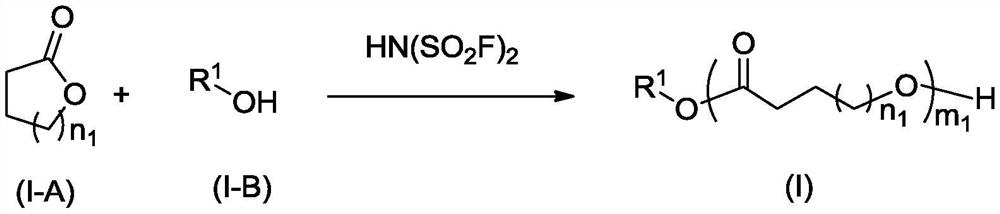

[0278] In a 25ml three-necked flask, add 1.9998g (17.54mmol, 1eq) of caprolactone, 5ml of dichloromethane, 175ul concentration of phenylpropanol dichloromethane solution (1%eq) of 1mol / L, add 35ul under nitrogen protection conditions The dichloromethane solution (0.1% eq) of bisfluorosulfonylimide acid with a concentration of 0.5mol / L was reacted overnight at room temperature. Lactone solid 1.86g (yield 93%) was detected by GPC, Mn PS =25267, PDI=1.03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com