Method for preparing Vaccinium dunalianum extract through microwave synergistic composite enzymatic hydrolysis

A compound enzymatic hydrolysis and extraction technology, which is applied in the direction of sugar derivatives, drug combinations, pharmaceutical formulations, etc., can solve the problems of not fully meeting the needs of use, low yield of active ingredients, long extraction time, etc., to achieve excellent supply Effects of hydrogen capacity, few steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

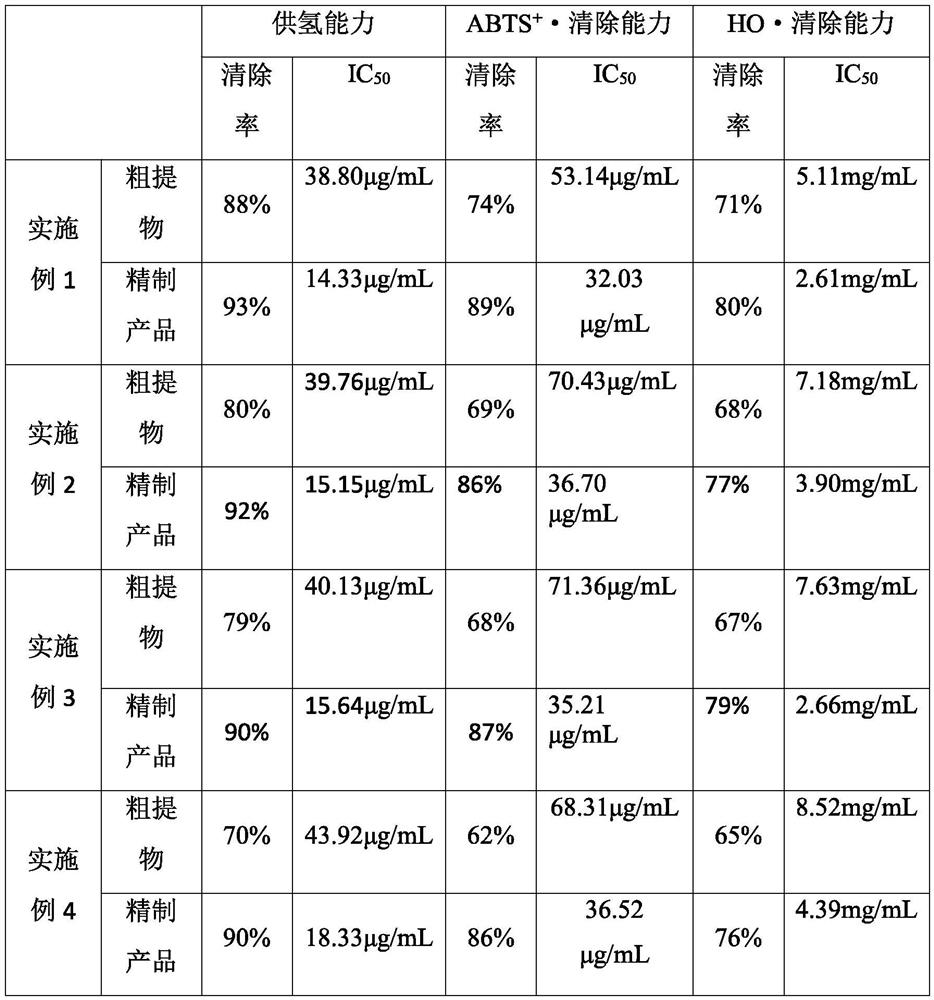

Embodiment 1

[0030] Raw material pretreatment

[0031] The leaf buds were collected by Judy Orange. After naturally drying, it was pulverized to 60 mesh, and the powder sample was pretreated after the ultraviolet lamp was prepared, and the dry grinding bottle was loaded, and the spare was stored at 4 ° C.

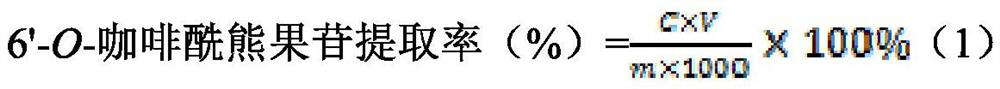

[0032] 2. Extraction and refining of active ingredients

[0033] Precisely referred to in the pre-treatment of the sediment 5.0000g added to the microwave extraction bottle, the liquid ratio (g / mL) is added to 1: 30 to add deionized water as extracting solvent, add sample mass 2% composite enzyme (fiber) Surrsenase: pectin enzyme = 2: 1), the microwave extraction power is 600 W, and the extraction temperature is 50 ° C in the constant temperature water bath. After the end of the enzymatic solution, the enzyme was oxidase 10 min in hot water at 75 ° C. After cooling, filtrate, the filtrate was concentrated under reduced pressure, dried to constant weight to the constant weight, and the bro...

Embodiment 2

[0035]Raw material pretreatment with Example 1, precisely referred to in the pre-treatment of the Upperburder powder 5.0000g added to the microwave extraction bottle, and the liquid ratio (g / mL) is added to the addition of deionized water as extraction solvent, add Sample mass 2% compound enzyme (cellulase: pectin enzyme = 1: 0), microwave extraction power is 500 W, and the extraction temperature is 40 ° C in a constant temperature water bath in a constant temperature water bath. After the end of the enzymatic solution, the enzyme was oxidase 10 min in hot water at 75 ° C. After cooling, filtrate, the filtrate was concentrated under reduced pressure, dried to the constant weight to the constant weight, and the brown-yellow amorphous solid powder, the extraction rate was 18%, and the product was recrystallized by methanol, light yellow The needle crystals, the purity is ≥90%, and the yield is 90%. Among them, the methanol recrystallization is purified to: prepare the extract to f...

Embodiment 3

[0037] Raw material pretreatment with Example 1, accurately referred to in the pre-treatment of the suspended orange leaf bud powder 5.0000g added to the microwave extraction bottle, the liquid ratio (g / mL) 1: 50 is added to the extracting solvent, add Sample mass 2% complex enzyme (cellulase: pectin enzyme = 0: 1), microwave extraction power is 400 W, and the extraction temperature is 45 ° C constant temperature water bath enzymatic solution 2.5 h. After the end of the enzymatic solution, the enzyme was oxidase 10 min in hot water at 75 ° C. After cooling, filtrate, the filtrate was concentrated under reduced pressure, and the mixture was dried at 80 ° C to the crude extract of the Yulipin orange, the brown-yellow amorphous solid powder, the extraction rate was 17%, and the product was recrystallized by methanol, pale yellow Needle crystals, purity ≥ 90%, yield is 88%. Among them, the methanol recrystallization is purified to: prepare the extract to form a hot saturated saturat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com