Sea urchin-shaped nickel-cobalt hydrotalcite stainless steel net film and preparation method and application thereof

A stainless steel mesh and sea urchin-shaped technology, applied in the field of water treatment, can solve problems such as difficulty in applying large-scale industrial production, difficult to meet oil-water separation, complex and cumbersome preparation process, etc., achieve excellent anti-pollution ability, excellent anti-oil pollution ability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

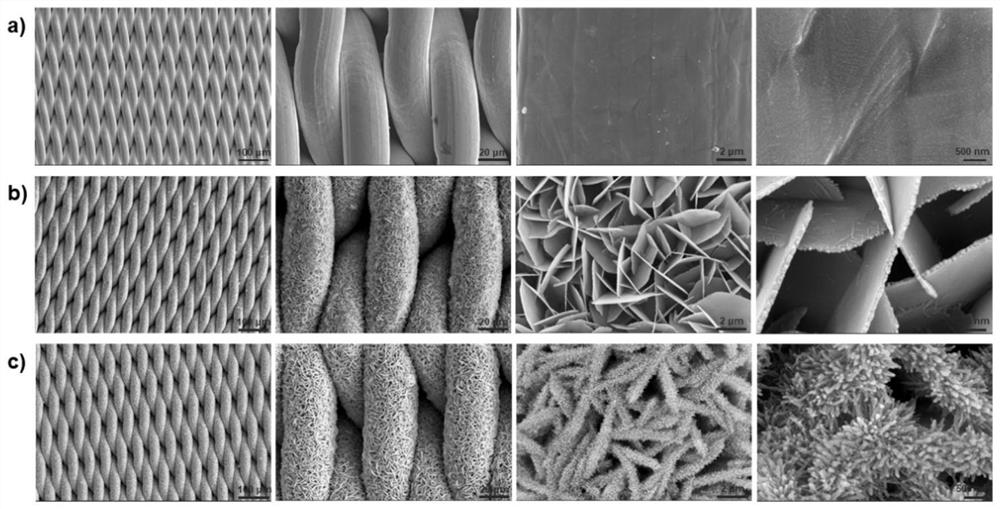

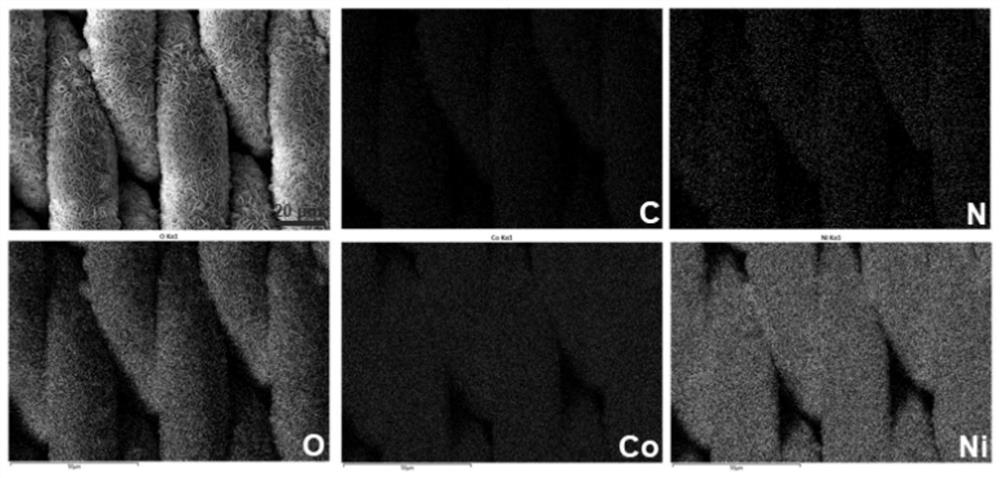

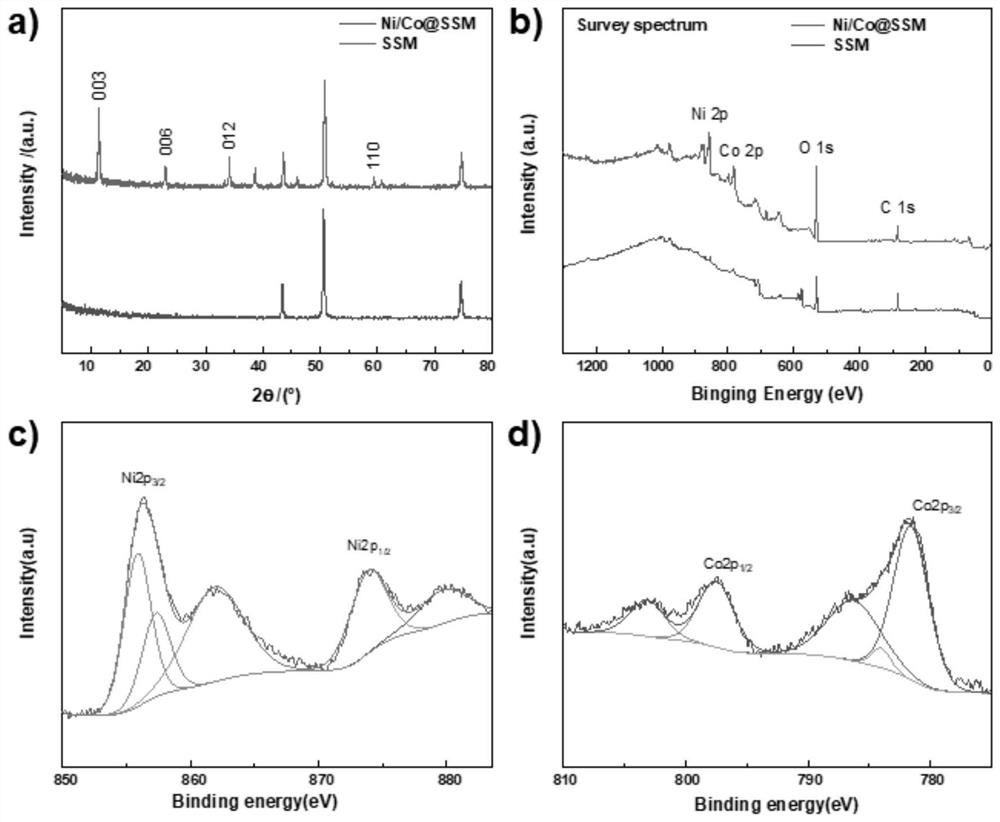

[0047] A sea urchin-like nickel-cobalt hydrotalcite stainless steel mesh is prepared through the following steps:

[0048] (1) Take a 2500-mesh stainless steel mesh and cut it into a square with a size of 5cm×5cm, and wash it with ethanol and deionized water for several minutes;

[0049] (2) Carry out surface hydroxylation treatment to the cleaned stainless steel mesh, specifically: configure piranha solution, take the cleaned stainless steel mesh and put it into the piranha solution, react at 60°C for 3 hours, and take out the stainless steel mesh and washed with deionized water, and stored in deionized water for later use;

[0050] (3) Weigh 4mmol of nickel nitrate hexahydrate, 2mmol of cobalt nitrate, 25mmol of urea and 8mmol of ammonium fluoride and dissolve in 120mL of deionized water, and disperse evenly by ultrasonic to obtain a precursor solution;

[0051] (4) Transfer the precursor solution to a 200mL polytetrafluoroethylene hydrothermal kettle, put the stainless ste...

Embodiment 2

[0054] Different from Example 1, the mesh number of stainless steel in step (1) in this example is 2000 mesh.

Embodiment 3

[0056] The difference from Example 1 is that step (2) in this example uses a mixed solution of sodium hydroxide and sodium persulfate to oxidize the cleaned stainless steel mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com