Modified polymer adsorbent for selectively adsorbing and recycling precious metal ions and preparation method ofmodified polymer adsorbent

A noble metal ion, adsorption recovery technology, applied in chemical instruments and methods, other chemical processes, improvement of process efficiency, etc., can solve the problems of low adsorption rate and high cost of precursor synthesis, to improve the adsorption rate and facilitate industrialization The effect of mass production and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] One embodiment of the present invention proposes a method for preparing a modified polymer adsorbent that selectively absorbs and recovers precious metal ions, which is characterized in that it includes the following steps:

[0039] 1) Mix sulfur element, polyamine-based compound, polycarbonyl compound, and loading substrate, add an organic solvent, and obtain a solid-liquid mixture;

[0040] 2) Under a protective gas atmosphere, the above-mentioned solid-liquid mixture is heated and reacted to obtain a modified polymer mixture;

[0041] 3) cooling the above-mentioned modified polymer mixed solution to room temperature, washing, centrifuging, and drying to obtain a modified polymer adsorbent;

[0042] Wherein, the supporting substrate is a porous adsorption material.

[0043] The preparation method of the modified polymer adsorbent proposed in the embodiment of the present invention for selectively adsorbing and recovering precious metal ions, adopts the method of load...

Embodiment 1

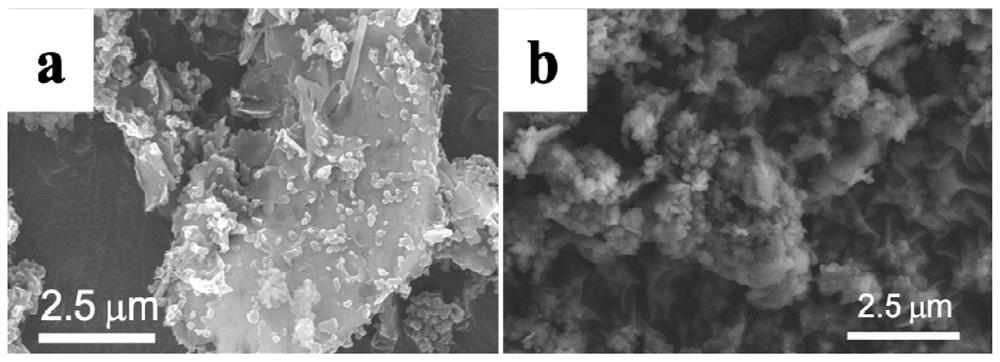

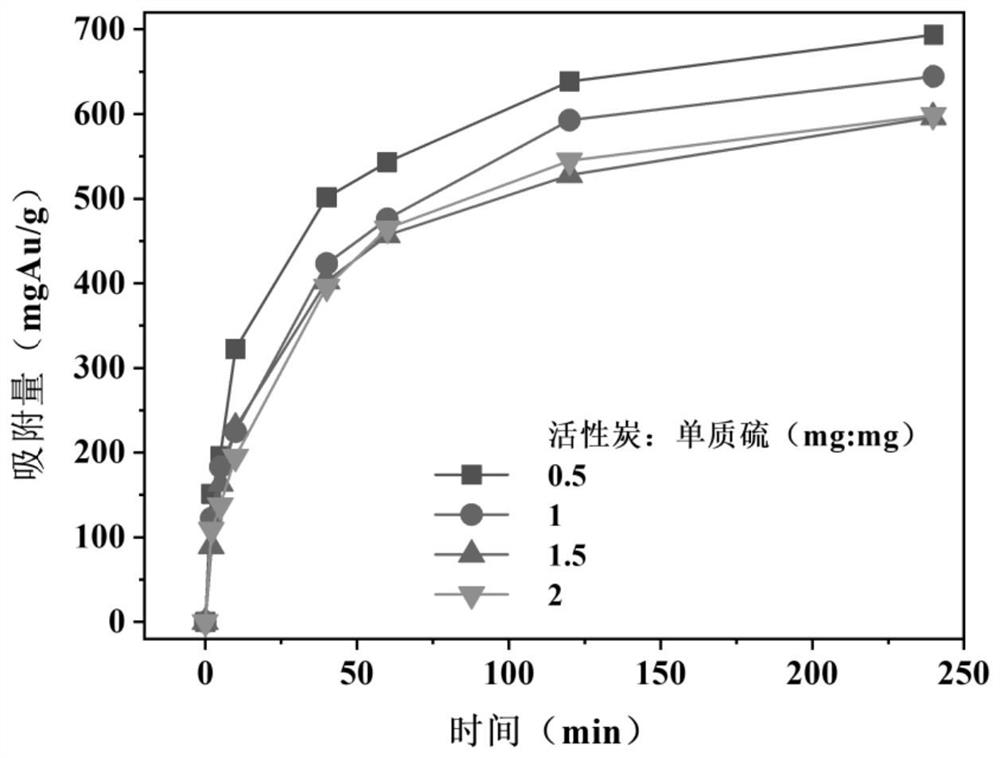

[0074] Example 1 A preparation method of a modified polymer adsorbent for selectively adsorbing and recovering precious metal ions, comprising the steps of:

[0075] (1) Weigh 48.1mg of elemental sulfur, 145.6mg of terephthalic acid, 58.1mg of hexamethylenediamine and a certain mass of activated carbon (24mg, 48mg, 72mg, 96mg) into a 20mL pressure-resistant tube, add 2mL of N,N- Methyl acetamide, add a magnetic rotor and stir for 12 minutes, put it into an ultrasonic instrument and sonicate for 12 minutes to obtain a solid-liquid mixture;

[0076] (2) Vacuumize the solid-liquid mixture obtained in step (1) until there are no bubbles, fill it with nitrogen, and heat it to 100° C. to react for 15 hours to obtain a modified polymer mixture;

[0077] (3) Add 4 mL of N,N-dimethylformamide to the modified polymer mixture obtained in step (2), stir for 10 minutes, slowly add it dropwise to 100 mL of methanol, centrifuge for 5 minutes, remove the supernatant and collect Precipitate...

Embodiment 2

[0092] Example 2 A preparation method of a modified polymer adsorbent for selectively adsorbing and recovering precious metal ions, comprising the steps of:

[0093] (1) Weigh 481mg of elemental sulfur, 1750mg of piperazine, 1660mg of terephthalaldehyde and 200mg of polyurethane into a pressure-resistant tube, add 20mL of N,N-dimethylacetamide, add a magnetic rotor to stir for 12 minutes, and put it into an ultrasonic instrument Ultrasound for 12 minutes to obtain a solid-liquid mixture;

[0094] (2) Vacuumize the solid-liquid mixture obtained in step (1) until there are no bubbles, fill it with nitrogen, and heat it to 100° C. to react for 15 hours to obtain a modified polymer mixture;

[0095] (3) Slowly add the modified polymer mixture obtained in step (2) dropwise into 200mL methanol, centrifuge for 5 minutes, remove the supernatant to collect the precipitate; then wash the precipitate with methanol, and centrifuge again after washing Treat for 5 minutes, remove the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com