Exfoliated tubular carbon nitride photocatalyst and preparation method and application thereof

A photocatalytic reaction and catalyst technology, applied in the field of visible light catalysis, can solve the problems of dangerous operating environment, tubular structure damage, harsh conditions, etc., and achieve the effects of excellent photocatalytic performance, low recombination rate, and many active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

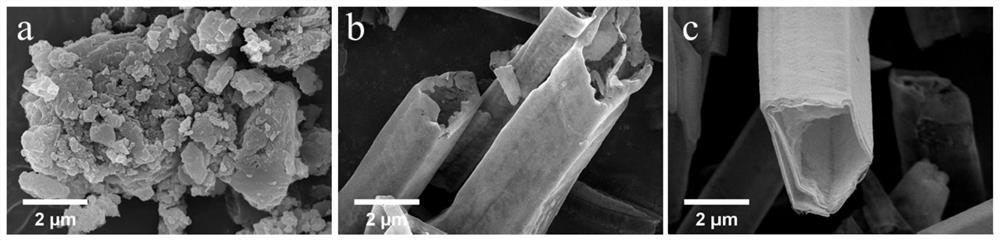

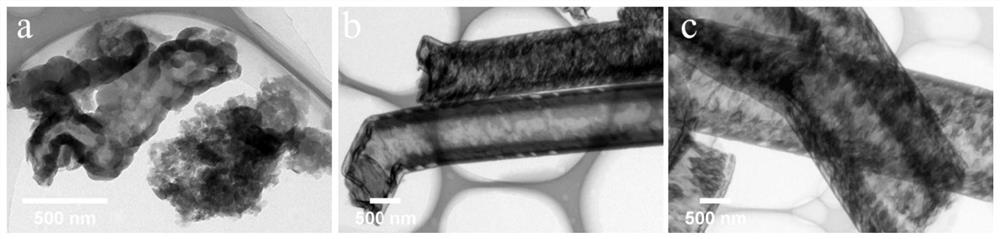

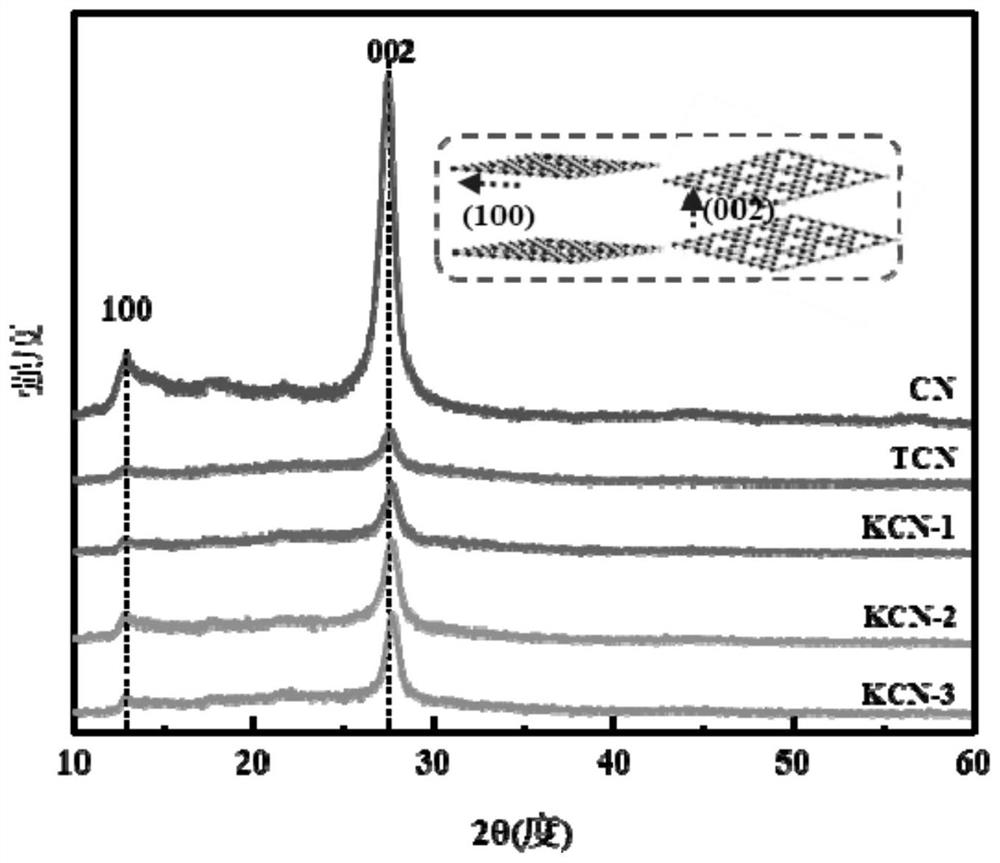

[0053] A method for preparing a peeling tubular carbon nitride photocatalyst, which is prepared by hydroelectric processes and calcination in melamine and potassium bromide, including the following steps:

[0054] S1, 1.26 g of melamine in 80 ml of pure water, heated under a water bath at 80 ° C and stirred at a rotational speed of 300 rpm, and the melamine was completely dissolved in water to obtain a clear solution.

[0055] S2, 0.357 g of potassium bromide was added to the clarified solution obtained in step S1, continued to heat at 80 ° C water bath and stirred at a rotational speed for 30 min, resulting in a clear mixing solution.

[0056] S3, transferring the mixed solution obtained in step S2 to 100 ml of autoclave, water heat reactions at 180 ° C for 10 h, after natural cooling, the resulting reaction product was purified 3 times with pure water, filtration at a temperature of 40 ° C It was dried at 60 ° C for 12 h to give the precursor.

[0057]S4, put the precursor obtai...

Embodiment 2

[0073] A release tubular carbon nitride photocatalyst in degradation of organic contaminants, specifically, the peeling tubular carbon nitride photocatalyst (KCN-1, KCN-2, KCN-3) prepared using the extract (KCN-1, KCN-2, KCN-3) in Example 1. Tetracycline in hydrochloride, including the following steps:

[0074] The peeling tubular carbon nitride photocatalyst (KCN-1, KCN-2, KCN-3) prepared in Example 1 and the unlimited monomerified carbon nitride photocatalyst (CN) obtained in Comparative Example 1 The unfoliated tubular carbon nitride photocatalyst (TCN) prepared in Comparative Example 2, each of which was added to 50 mL, and the concentration of 10 mg / L, a pH of a hydrochloride (TCH) solution having a pH of 4.86, mixed Uniform, in the case of room temperature and 300 rpm, the hydrochloride tetracyransin is darkened, and the adsorption desorption balance is reached after 30min; the mixture reaches the adsorption equilibrium is placed under a xenon lamp (λ> 420 nm), and light a...

Embodiment 3

[0077] A release tubular carbon nitride photocatalyst is degraded in degraded organic contaminants, in particular to degrade the tubular carbon nitride photocatalyst (KCN-2) prepared in Example 1 to degrade the tetracycline in different pH hydrochlorides, Include the following steps:

[0078] The peeling tubular carbon nitride photocatalyst (KCN-2) obtained in Example 1 was taken, each of which was added to a hydrochloride (TCH) solution added to the initial pH of 3, 5, 7, 9, 11, respectively. (These solutions were 50 ml, the concentration was 10 mg / L), mixed uniform, darkened with tetracycline of hydrochloride under conditions of room temperature, 300 rpm, and reached adsorption desorption balance after 30min; a mixture of adsorption equilibrium Under xenon lamp (λ> 420 nm), a photocatalytic reaction was carried out at room temperature and 300 rpm for 90 min, and the treatment of tetracycline (TCH) of hydrochloride was completed.

[0079] Figure 9 The degradation effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com