Macromolecular composite repairing material for circulating water pump and repairing method of macromolecular composite repairing material

A technology for circulating water pumps and repairing materials, applied in the field of machinery, can solve problems such as corrosion, lack of good solutions, and prolong the service life of equipment, and achieve the effects of increasing reliability, delaying small hole corrosion, and delaying chemical corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

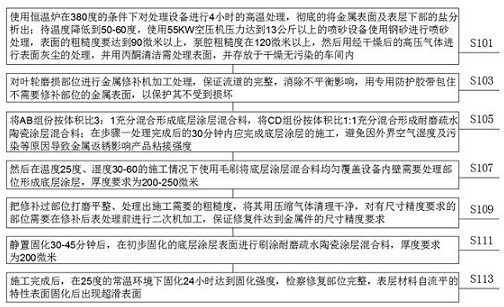

Method used

Image

Examples

Embodiment 1

[0028] According to an embodiment of the present invention, a polymer composite repair material for a circulating water pump is provided. , including the following raw material components: 1 part of the bottom coating mixture and 1 part of the wear-resistant hydrophobic ceramic coating, the bottom coating mixture includes: 3 parts of A component repair material, 1 part of B component repair material;

[0029] The component A repair material includes the following main components: 70% epoxy modified resin, 10% silicon carbide, 3% alumina powder, 2% rutile titanium dioxide, 10% ceramic particles, 2.5% zinc-aluminum powder, plasticizer Agent KH550 0.5%, zirconia 300 mesh 1%, graphite superfine powder 1%;

[0030] The component B repair material includes the following main components: 80% modified amine curing agent, 5% GPM-800, 5% silane coupling agent, and 10% composite accelerator.

[0031] Wherein, the wear-resistant hydrophobic ceramic coating includes: 1 part of C component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com