Acid-resistant non-curing waterproof coating and preparation process thereof

A technology of waterproof coating and preparation process, applied in the direction of asphalt coating, coating, etc., can solve the problems of loss of waterproof coating function, material performance attenuation, deterioration of waterproof coating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

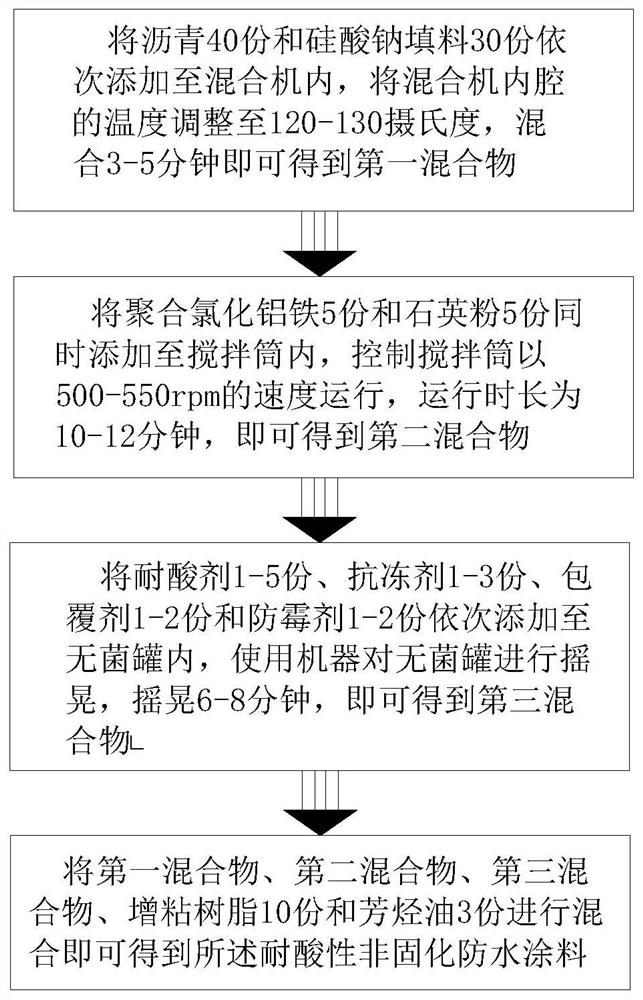

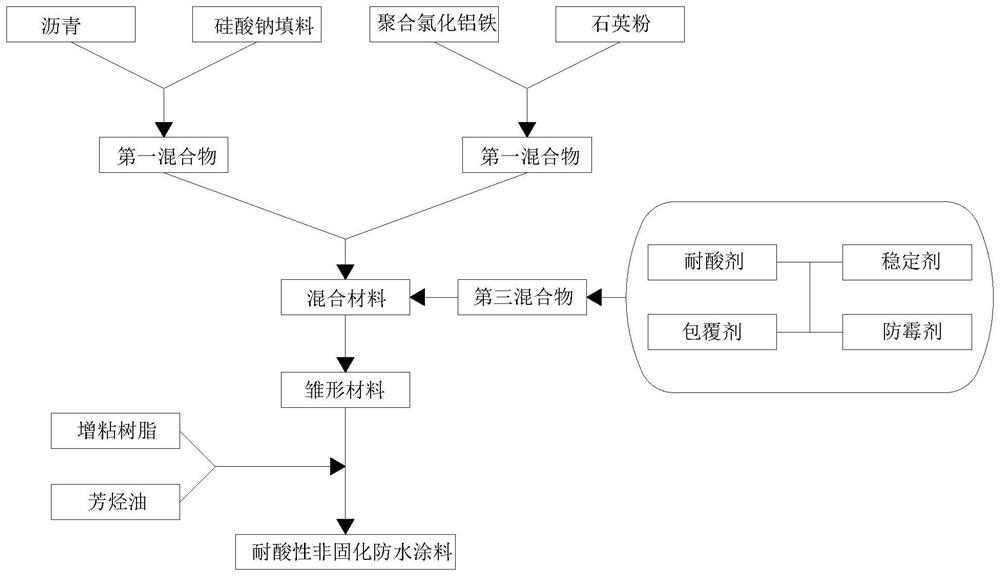

[0037] First aspect, such as Figure 2-5 As shown, the present invention provides an acid-resistant non-curing waterproof coating, and the raw material components are as follows in parts by weight: 40 parts of asphalt, 30 parts of sodium silicate filler, 10 parts of tackifying resin, 3 parts of aromatic hydrocarbon oil, polymerized chlorine 5 parts of aluminum iron, 5 parts of quartz powder, 1-5 parts of acid resistant agent, 1-3 parts of antifreeze agent, 1-2 parts of coating agent, and 1-2 parts of mold inhibitor.

[0038] In this embodiment, through the design of sodium silicate filler, the characteristics of strong cohesive force, high strength, acid resistance, heat resistance and alkali resistance of the sodium silicate filler make the cohesive force and strength of the waterproof coating , Acid resistance, heat resistance and alkali resistance are greatly improved, and the practical performance of waterproof coatings is increased. By setting aromatic oil, because aromat...

Embodiment 2

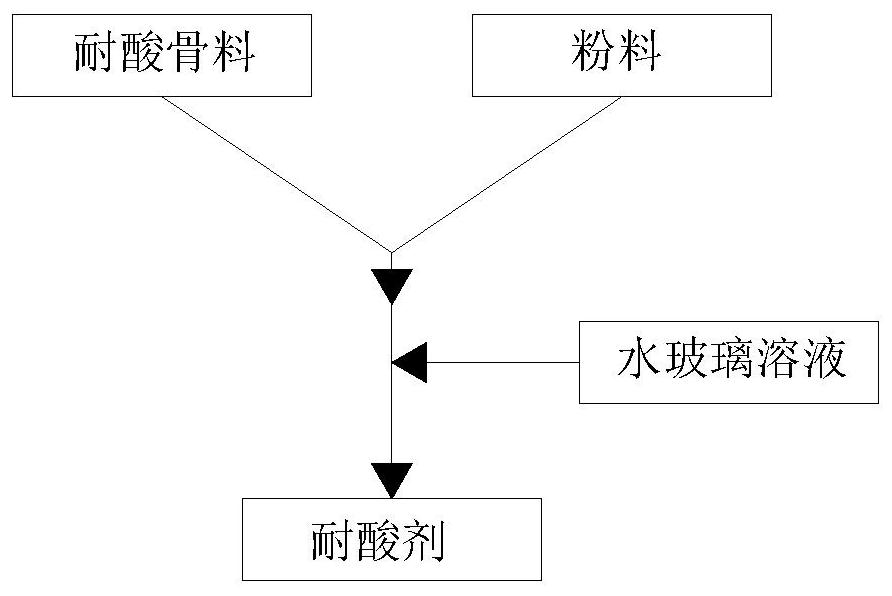

[0040] Such as Figure 2-5 As shown, on the basis of Example 1, the present invention provides a kind of technical scheme: preferably, after the acid-resistant agent is uniformly mixed and stirred by 70wt% of acid-resistant aggregate, 20wt% of powder and 10wt% of water glass solution, add an appropriate amount of The coagulant is mixed and made, the antifreeze agent is made by uniformly mixing 40wt% of slag powder, 6wt% of zeolite powder, 50wt% of cement, 4wt% of aluminum slag powder and an appropriate amount of water, and the coating agent is made of petroleum resin 60wt%, reducing 20wt% of second-line distillate oil, 10wt% of lubricating oil and 10wt% of low molecular weight polyethylene wax were mixed for 5 minutes under the environment of 120 degrees centigrade.

[0041]In this embodiment, by providing a coating agent, it is beneficial to the mixing between the various ingredients of the waterproof material, and the effect and speed of mixing are improved. By providing an ...

Embodiment 3

[0043] Such as Figure 2-5 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, fungicide is made of phenol 90wt%, copper sulfate 3wt%, sodium fluoride 3wt% and aluminosilicate mineral carrier 4wt% uniform Made by mixing, aromatic oil can be replaced with mineral oil or rubber oil according to the environment of use.

[0044] In this embodiment, the main filler of the antifungal agent is designed to be phenol, which has the functions of inhibiting mold growth and killing mold, and can prevent polymer materials from being corroded by fungi, maintaining good appearance and physical and mechanical properties. There is an antifungal agent in the coating to avoid the growth of mold in the waterproof coating, which will affect the appearance of the wall, making the waterproof coating suitable for applications in environments with strong mold growth, and can keep the surface of the coating film free from mold for a long time. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com