Alkali-resistant compound microorganism pretreatment fungicide for pulping wheat straw and application of alkali-resistant compound microorganism pretreatment fungicide

A composite microorganism and pretreatment technology, which is applied in the use of microorganism/enzyme cellulose treatment, biological organic part treatment, microorganism-based method, etc. , achieve the effect of avoiding the use of chemical preparations, strong adaptability and universality, and high degree of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

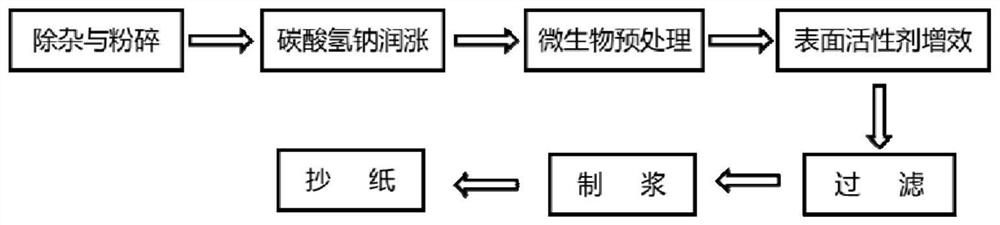

Method used

Image

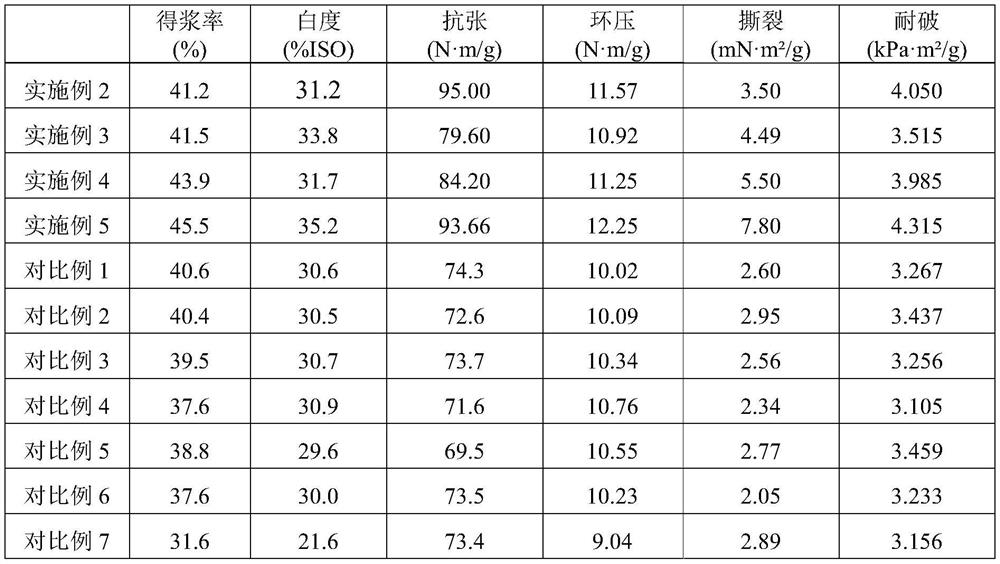

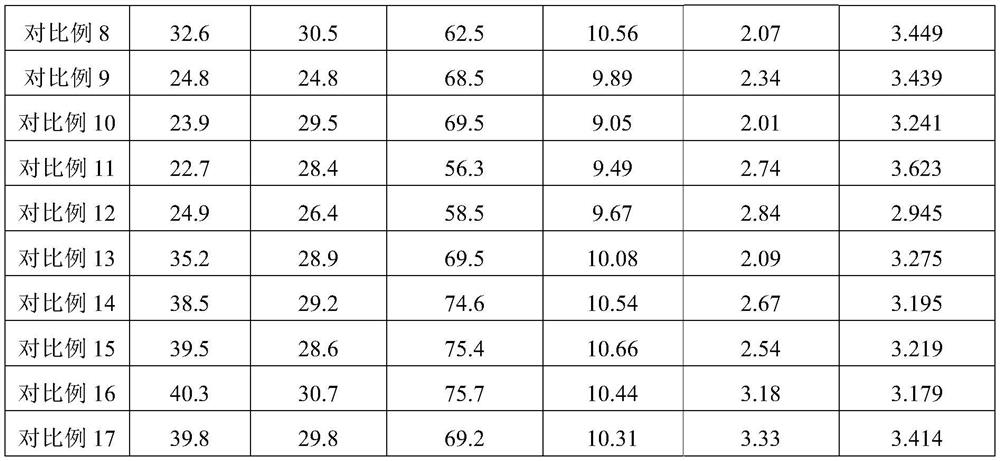

Examples

Embodiment 1

[0066] Determination of the strain composition in the alkali-resistant compound microbial pretreatment bacterial agent:

[0067] (1) Obtain the source of bacteria: collect wheat straw waste and cultivated soil samples, soak them in 0.85% saline for 2-3 days, so that the microorganisms in the samples can be fully dispersed into the liquid environment;

[0068] (2) Enrichment culture: draw a certain volume of the bacteria-containing liquid in step (1) and transfer it to a complete culture medium (liquid) for 2-3 days, the culture temperature is 37°C, 180rpm;

[0069] (3) Dilution coating: After gradient dilution, draw 200 μL of diluted bacterial solution and evenly spread it on the complete medium (solid), culture for 1-2 days, and the culture temperature is 37°C;

[0070] (4) Liquid transfer: Pick a single different colony and transfer to complete medium (liquid), culture for 2-3 days, culture temperature is 37°C, 180rpm;

[0071] (5) Purification by streaking: Streak the bact...

Embodiment 2

[0078] An alkali-resistant composite microbial pretreatment bacterial agent for wheat straw pulping, the preparation method steps are as follows:

[0079] 1) Strain activation: inoculate Bacillus licheniformis, Alcaligenes faecalis and Bacillus lysine in YPD liquid medium, inoculate Bacillus subtilis and Bacillus cereus in LB liquid medium, 37°C, 180rpm Activation culture for 1 day;

[0080] 2) Bacteria liquid culture: transfer the bacterium liquid after step 1) activation culture to the corresponding liquid culture medium, 37 ℃, 180rpm expand culture for 1 day, the number of viable bacteria of the obtained Bacillus licheniformis bacterium liquid is 3.0×10 9 cfu / mL, the number of viable bacteria in Alcaligenes faecalis solution is 3.0×10 9 cfu / mL, the number of viable bacteria in the Bacillus lysinus solution is 2.0×10 10 cfu / mL, the number of viable bacteria in the Bacillus subtilis liquid is 2.0×10 9 cfu / mL, the number of viable bacteria in the Bacillus cereus liquid is 4...

Embodiment 3

[0091] An alkali-resistant composite microbial pretreatment bacterial agent for wheat straw pulping, the preparation method steps are as follows:

[0092] 1) Strain activation: inoculate Bacillus licheniformis, Alcaligenes faecalis and Bacillus lysine in YPD liquid medium, inoculate Bacillus subtilis and Bacillus cereus in LB liquid medium, 37°C, 180rpm Activation culture for 1 day;

[0093] 2) Bacteria liquid culture: transfer the bacterium liquid after step 1) activation culture to the corresponding liquid medium, 37 ℃, 180rpm expand culture for 2 days, the number of viable bacteria in the obtained Bacillus licheniformis bacterium liquid is 2.0×10 10 cfu / mL, the number of viable bacteria in Alcaligenes faecalis solution is 9.0×10 9 cfu / mL, the number of viable bacteria in the Bacillus lysinus solution is 8.0×10 10 cfu / mL, the number of viable bacteria in the Bacillus subtilis liquid is 2.0×10 10 cfu / mL, the number of viable bacteria in the Bacillus cereus liquid is 7.0×10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com