Method for detecting propyl gallate and formaldehyde

A technology of propyl gallate and formaldehyde, which is applied in the field of chemical analysis and detection to achieve the effects of rapid reaction, consistent detection results and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Determination of formaldehyde in PG and dried white fungus in soybean oil sample

[0027] 1. Preparation of zinc-based single-atom nanozyme Zn-N-C: Stir and mix 0.7g zinc acetate, 20mL methanol and 50g potassium chloride, place in a vacuum drying oven, dry at 80°C for 24h, mix the dried solid with 0.4g After mixing 2-methylimidazole and 20mL methanol, place in a vacuum oven, dry at 80°C for 48h to remove methanol, place the obtained solid particles in a tube furnace, and calcinate at 750°C for 2h under the protection of nitrogen, and wash the obtained solid with pure water Wash to obtain small black particles insoluble in water, namely Zn-N-C;

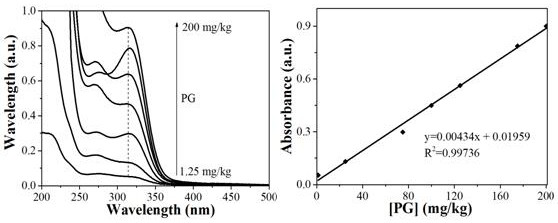

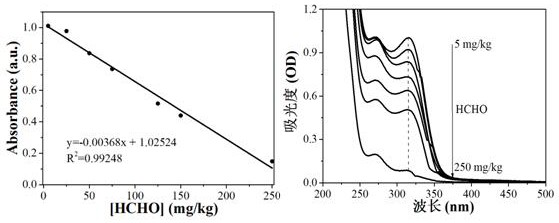

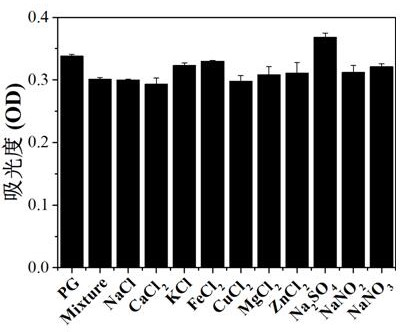

[0028] 2. Preparation of the working curve of propyl gallate: add 0.1mg / mL zinc-based single-atom nanozyme (Zn-N-C) 100µL, 50mmol / L H 2 o 2 100µL standard solution of propyl gallate with a concentration in the range of 1.25~200mg / kg, dilute to the mark with citric acid-disodium hydrogen phosphate buffer solution ...

Embodiment 2

[0042] Example 2: Determination of formaldehyde in PG and chicken feet in blended oil samples

[0043] 1, Zn-N-C preparation: with embodiment 1;

[0044] 2, the making of propyl gallate working curve: with embodiment 1;

[0045] 3, formaldehyde working curve making: with embodiment 1;

[0046] 4. Determination of PG in blend oil samples

[0047] (1) Sample treatment: Accurately weigh 2g of blended oil into a 25mL colorimetric tube, add 7mL of ethanol solution with a volume concentration of 95%, vortex for 1min to mix well, let it stand for a while, and heat it in a water bath at 85°C for 15s to promote its separation. layer; transfer the supernatant to the concentration bottle with a straw, then repeat the extraction twice with 7mL 95% ethanol solution, combine the extracts and dilute to 25mL to obtain the sample solution to be tested;

[0048] (2) Sample determination: Same as in Example 1, the content of PG in the blended oil sample was 11.21 mg / kg.

[0049] 5. Determina...

Embodiment 3

[0052] Embodiment 3: Determination of PG in cookies and formaldehyde in shredded bread

[0053] 1. Preparation of Zn-N-C: Stir and mix 1g of zinc acetate, 20mL of methanol and 50g of potassium chloride, place it at 80°C for 30h in vacuum, and mix the dried solid with 0.3g of 2-methylimidazole and 23mL of methanol After that, place it at 80°C for 30 hours to remove methanol, place the obtained solid particles in a tube furnace, and calcinate at 800°C for 2 hours under the protection of nitrogen, and wash the obtained solids with pure water to obtain small black particles that are insoluble in water. It is zinc-based single-atom nanozyme Zn-N-C;

[0054] 2, making of propyl gallate working curve: with embodiment 1.

[0055] 3, formaldehyde working curve making: with embodiment 1;

[0056] 4. Determination of PG in cookies

[0057] (1) Sample treatment: Weigh 5.00g of evenly powdered biscuit sample into a 100mL Erlenmeyer flask, add 8mL of absolute ethanol, vortex mix for 1min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com