Anti-counterfeiting adhesive tape with magnetic response and biodegradation functions as well as preparation method and application of anti-counterfeiting adhesive tape

A technology of biodegradable and anti-counterfeiting tape, which is applied in the field of anti-counterfeiting, can solve the problems of affecting the laser marking performance of the tape, reducing the overall performance of the tape, and decreasing, and achieves the effect of excellent near-infrared laser absorption characteristics and improving the anti-counterfeiting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

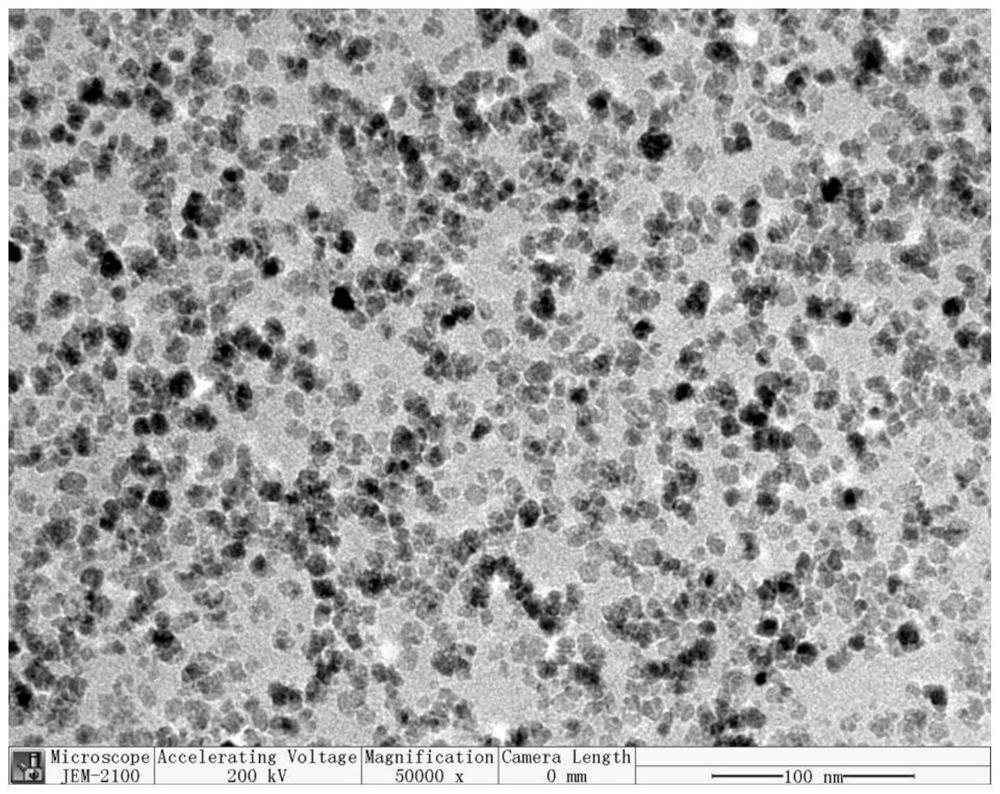

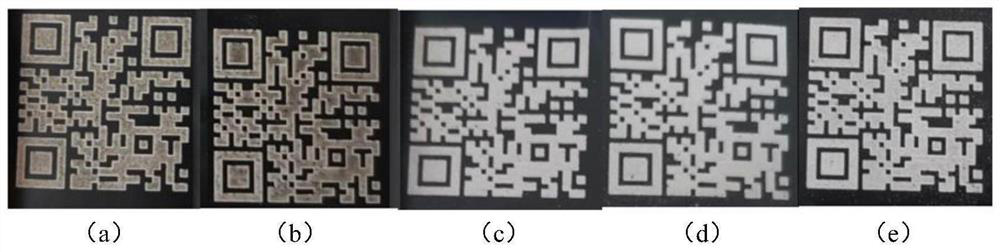

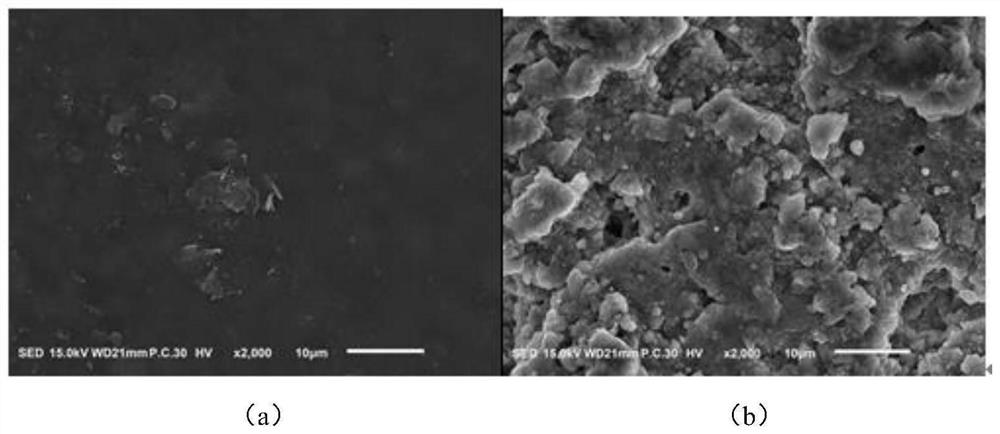

Method used

Image

Examples

Embodiment 1

[0036] Adopting the method of the present invention to prepare the anti-counterfeiting adhesive tape with magnetic response and biodegradation function comprises the following steps:

[0037] (1) Preparation of modified substrate film layer

[0038] The polycarbonate film is selected as the substrate film, and the modified substrate film is prepared through a surface modification process. First, chitosan, acrylamide, initiator, crosslinking agent, and water are configured into a precursor solution according to a certain ratio. The mass concentration of acrylamide in the precursor solution is 20%, and the input mass of chitosan accounts for 10% of propylene. 5% of the input quality of the amide, the input quality of the photoinitiator 2960 accounts for 0.5% of the input quality of the acrylamide, and the input quality of the crosslinking agent N, N-methylenebisacrylamide accounts for 0.1% of the input quality of the acrylamide; The carbonate film was immersed in the above prec...

Embodiment 2

[0048] Adopting the method of the present invention to prepare the anti-counterfeiting adhesive tape with magnetic response and biodegradation function comprises the following steps:

[0049] (1) Preparation of modified substrate film layer

[0050] The polyethylene terephthalate film is selected as the substrate film, and the modified substrate film is prepared through a surface modification process. First, chitosan, acrylamide, initiator, crosslinking agent, and water are configured into a precursor solution according to a certain ratio. The mass concentration of acrylamide in the precursor solution is 25%, and the input mass of chitosan accounts for 10% of propylene. 6% of the input quality of the amide, the input quality of the photoinitiator 2960 accounts for 1% of the input quality of the acrylamide, and the input quality of the crosslinking agent N, N-methylenebisacrylamide accounts for 0.5% of the input quality of the acrylamide; The carbonate film was immersed in the...

Embodiment 3

[0061] Adopting the method of the present invention to prepare the anti-counterfeiting adhesive tape with magnetic response and biodegradation function comprises the following steps:

[0062] (1) Preparation of modified substrate film layer

[0063] The polypropylene film is selected as the base film, and the modified base film is prepared through the surface modification process. First, chitosan, acrylamide, initiator, crosslinking agent, and water are configured into a precursor solution according to a certain ratio. The mass concentration of acrylamide in the precursor solution is 30%, and the input mass of chitosan accounts for 10% of propylene. 7% of the input quality of the amide, the input quality of the photoinitiator 2960 accounts for 1.5% of the input quality of the acrylamide, and the input quality of the crosslinking agent N, N-methylenebisacrylamide accounts for 1% of the input quality of the acrylamide; The carbonate film was immersed in the above precursor solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com