Metal ceramic material for aluminum electrolysis inert anode and preparation method thereof

A cermet and inert anode technology, applied in the field of cermet materials for aluminum electrolysis inert anodes, can solve the problems of affecting the service life of electrodes, difficulty in further improving the density and conductivity of cermets, and limiting the content of alloy components in cermets, etc. To achieve the effect of improving corrosion resistance, high density, and improving sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

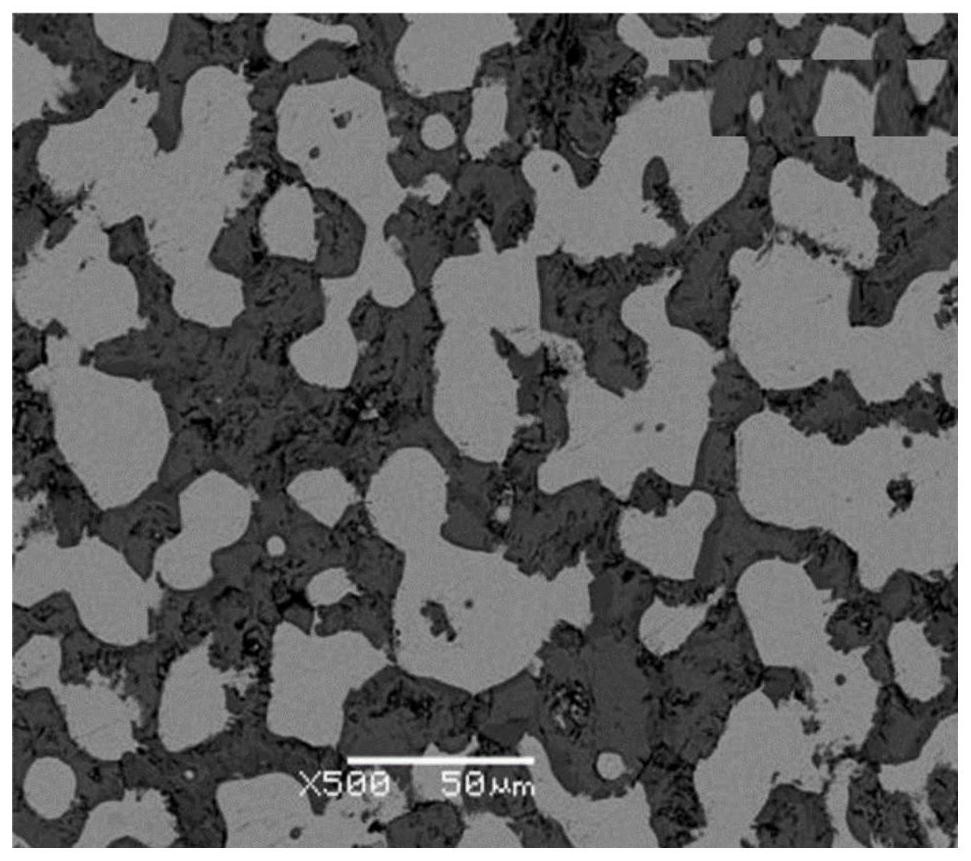

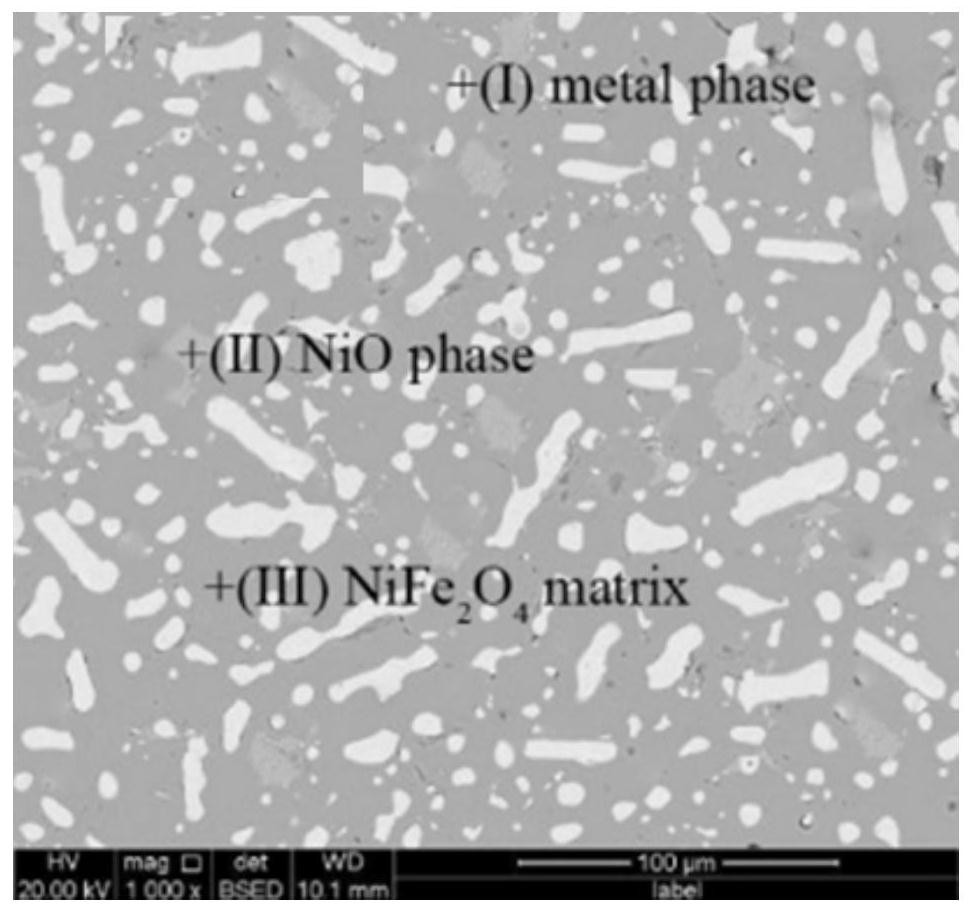

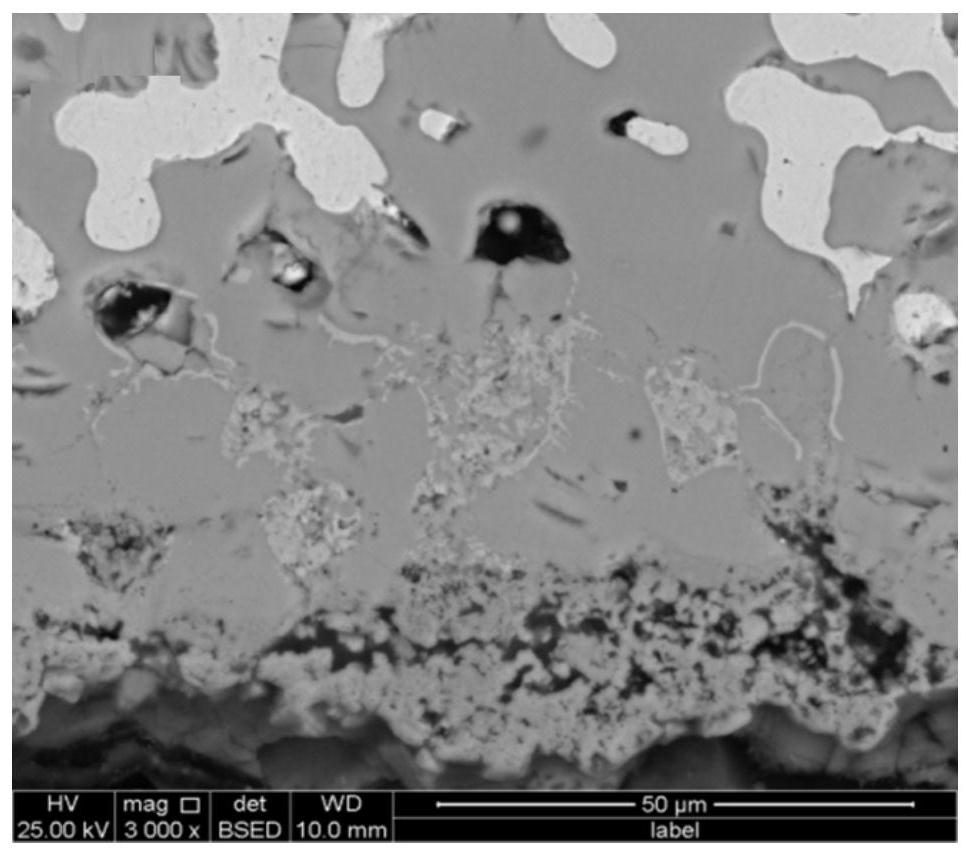

Embodiment 1

[0073] A cermet material of an aluminum electrolytic inert anode is formed by pressing a steel mold. Calculated by mass fraction, the alloy phase content is 40%, and the elements and contents contained in the alloy phase are: 40% Fe, 5% Cu, 45% Ni, 8% Co, 2% Cr, and the alloy phase passes through the metal elemental powder Obtained after mixing in proportion. Ceramic phases are NiO and Fe 2 o 3 Composite oxide powder obtained by high-temperature calcination after the powder is uniformly mixed, and its composition is NiFe 2 o 4 +10% NiO, containing 0.5% BaO sintering aid. After the alloy phase powder and the ceramic phase powder are mixed in proportion, the cermet powder is obtained, and the cermet powder is pressed-sieved (-40 mesh+100 mesh) to obtain the cermet granulated powder, and then 1% of the total weight of the powder is added Stearic acid is used as a molding agent, mixed evenly, and then pressed into a steel mold at 100MPa to obtain a green body, and then sinter...

Embodiment 2

[0076] A cermet material for an aluminum electrolytic inert anode is formed by cold isostatic pressing. Calculated by mass fraction, the alloy phase content is 50%, and the elements and contents contained in the alloy phase are: 60% Fe, 30% Cu, 7% Ni, 3% Mn, and the raw material of the alloy phase is gas atomized alloy pink. The ceramic phase is 10% NiO, 3% MnO 2 and Fe 2 o 3 Composite oxide powder obtained by calcination at high temperature after uniform mixing of powders. After mixing alloy powder and composite ceramic powder in proportion, add PVA binder accounting for 1% of the total weight of the powder; pass through a 100-mesh sieve after spray granulation to obtain cermet mixed powder, and then pass through 200MPa isostatic pressing The green body is obtained by molding, degreased at 500°C in a nitrogen atmosphere, and then sintered in a circulating mixed atmosphere containing oxygen and protective atmosphere, wherein the partial pressure of oxygen is 800Pa, the sin...

Embodiment 3

[0079] A cermet material for an aluminum electrolytic inert anode formed by gel injection molding. Calculated by mass fraction, the content of the alloy phase is 60%, and the composition is 50% Fe, 35% Cu, 10% Ni, 3% Cr, 1.4% Mn, 0.5% Zn, 0.1% Ta; the ceramic phase is NiFe 2 o 4 +10%NiO, sintering aid is 2%MnO 2and 0.5 BaO. Mix alloy phase and ceramic phase powders in proportion, and obtain cermet powder with an average particle size of 4-5 μm after ball milling and sieving, and then mix cermet powder accounting for 40% by volume, 15 % of hydroxyethyl methacrylate, 2% of 1,6-hexanediol diacrylate, and 1% of surfactants are added to n-octanol, and the content of polyvinyl alcohol in surfactants It is 80%, and the rest is stearylamine acetate. Then carry out wet ball milling, wherein the ball milling speed is 200r / min, and the ball milling time is 12h. Obtain the cermet suspension that each component mixes homogeneously by ball milling, then add tert-butyl peroxybenzoate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com