Single-layer fluorinated graphene Schottky diode and preparation method and application thereof

A Schottky diode and single-layer graphene technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of difficult adjustment of Schottky diode performance parameters, short reverse recovery time, and device performance degradation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

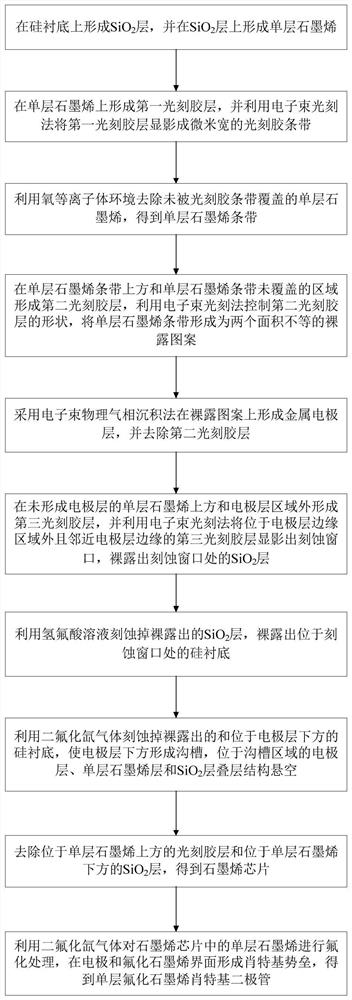

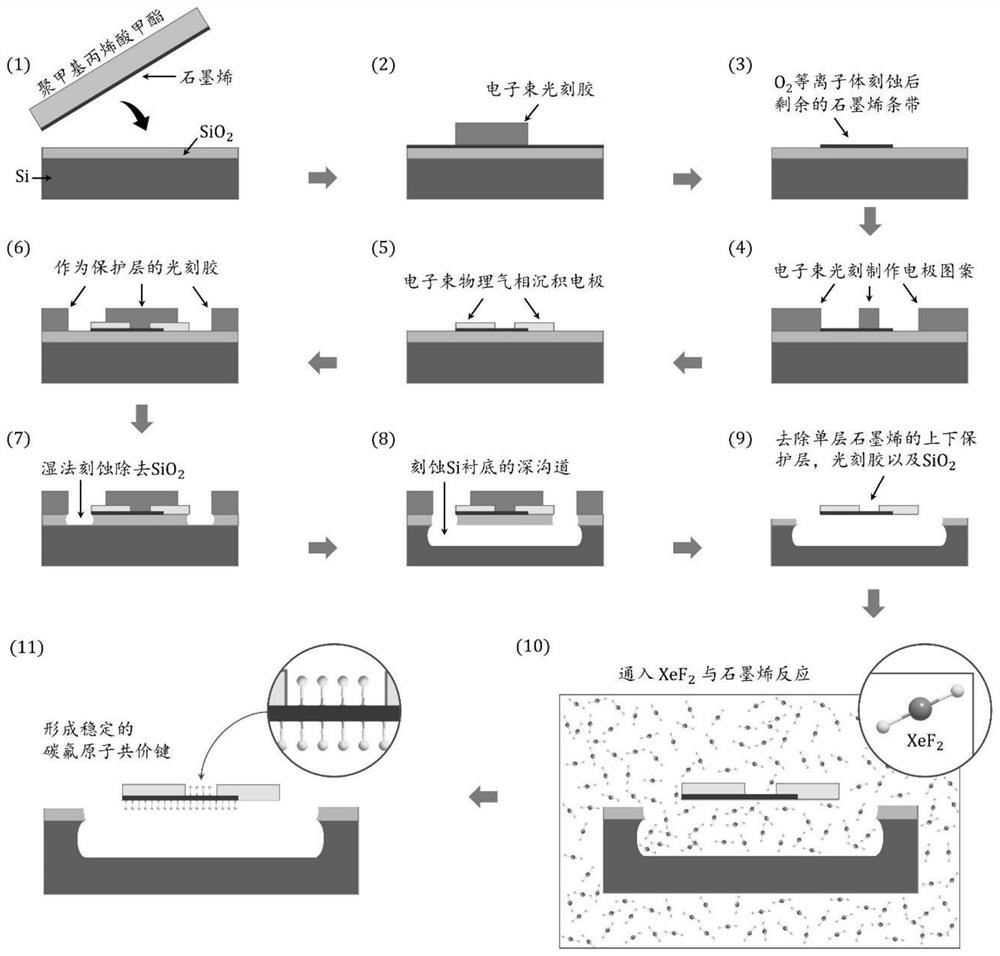

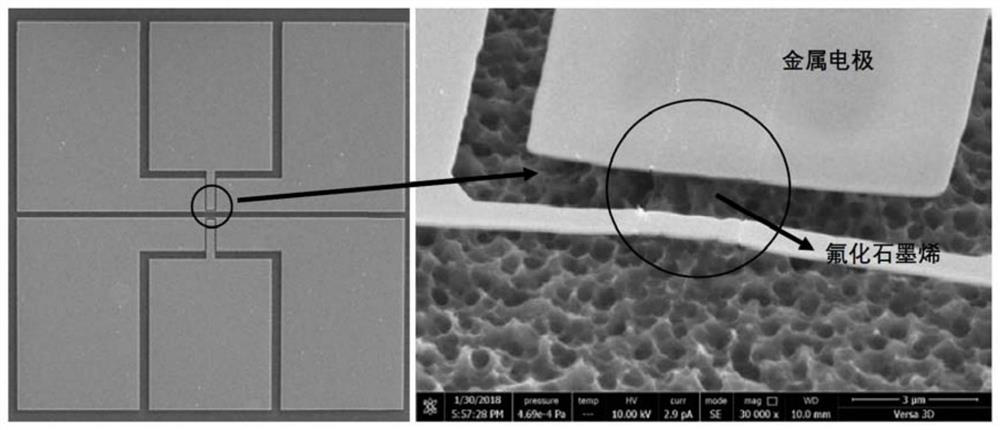

[0136] A preparation method of a novel monolayer fluorinated graphene Schottky diode. According to an embodiment of the invention:

[0137] (1) Firstly, it is necessary to prepare a graphene structure with a single-layer suspension, and the specific implementation is as follows:

[0138] (1-1) Single-layer graphene (SLG: Single-layer graphene) was prepared by chemical vapor deposition, and then transferred to a 100nm thick SiO 2 layer on a 4-inch Si wafer (as attached figure 2 (1)), and then cut it into chips with a size of 1cm×1cm for subsequent MEMS processing.

[0139] (1-2) Spin-coat a layer of electron beam photoresist (ZEP520A) with a thickness of 300nm on the surface of SLG, and use electron beam lithography to expose and develop the photoresist to form micron-wide photoresist strips (such as attached figure 2 shown in (2)).

[0140] (1-3) Expose the chip to O 2 (Oxygen) plasma for 30s, and etch away the SLG not covered by photoresist (as attached figure 2 sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com