Reflective heat-insulation coating for engineering machinery coating and preparation method of reflective heat-insulation coating

A technology of reflective heat-insulating coatings and construction machinery, applied in the direction of reflective/signal coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of low xenon lamp aging resistance, general aging resistance, and inability to prevent corrosion, and achieve insulation Good heat conduction performance and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

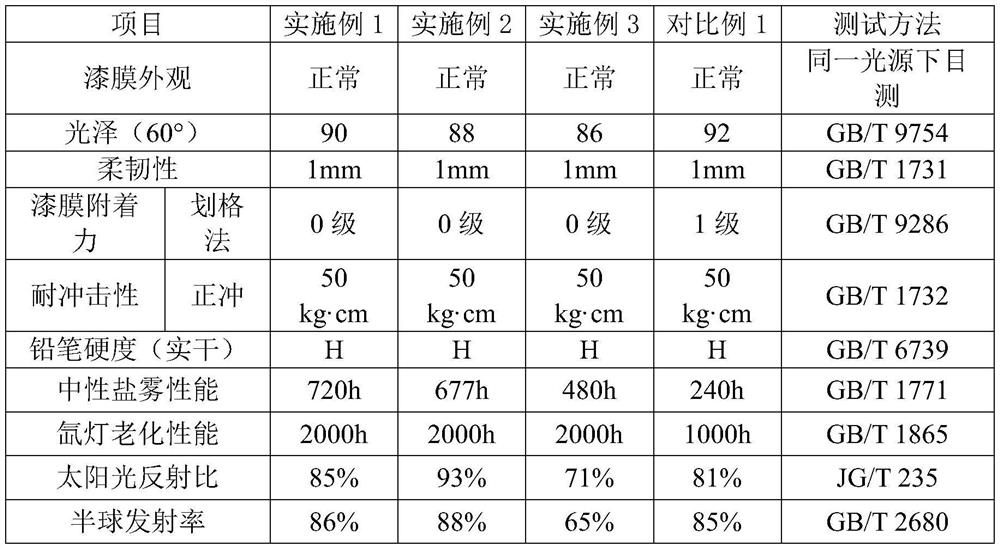

Examples

Embodiment 1

[0039] The reflective heat-insulating coating for construction machinery coating in this embodiment is composed of heat-insulating two-component epoxy primer and reflective heat-insulating two-component polyurethane topcoat;

[0040] The heat-insulating two-component epoxy primer is made by mixing component AI and component BI at a mass ratio of 5:1, wherein component AI is mixed with the following raw materials in parts by weight: bisphenol A ring 23 parts of oxygen resin, 15 parts of anatase titanium dioxide, 2 parts of carbon black, 8 parts of glass air microspheres, 2 parts of reflective heat insulation powder, 8 parts of zinc phosphate, 8 parts of heavy calcium, 10 parts of talcum powder, gas phase dioxide 0.5 parts of silicon, 1.0 parts of organobentonite, 0.1 parts of dispersant (BYK AT203, German BYK), 5 parts of diacetone alcohol, 7 parts of xylene, 10.4 parts of n-butanol; component BI is 50 parts of modified polyamide resin Mixed with 50 parts of methyl isobutyl ket...

Embodiment 2

[0051] The reflective heat-insulating coating for construction machinery coating in this embodiment is composed of heat-insulating two-component epoxy primer and reflective heat-insulating two-component polyurethane topcoat;

[0052] The heat-insulating two-component epoxy primer is made by mixing component AI and component BI at a mass ratio of 5:1, wherein component AI is mixed with the following raw materials in parts by weight: bisphenol A ring 21 parts of oxygen resin, 12 parts of anatase titanium dioxide, 2 parts of carbon black, 10 parts of glass air microspheres, 5 parts of reflective heat insulation powder, 8 parts of zinc phosphate, 8 parts of heavy calcium, 10 parts of talcum powder, gas phase dioxide 0.5 parts of silicon, 1.0 parts of organobentonite, 0.1 parts of dispersant (BYK AT203, German BYK), 5 parts of diacetone alcohol, 7 parts of xylene, 10.4 parts of n-butanol; component BI is 50 parts of modified polyamide resin Mixed with 50 parts of methyl isobutyl ke...

Embodiment 3

[0057] The reflective heat-insulating coating for construction machinery coating in this embodiment is composed of heat-insulating two-component epoxy primer and reflective heat-insulating two-component polyurethane topcoat;

[0058] The heat-insulating two-component epoxy primer is made by mixing component AI and component BI at a mass ratio of 5:1, wherein component AI is mixed with the following raw materials in parts by weight: bisphenol A ring 25 parts of oxygen resin, 15 parts of anatase titanium dioxide, 2 parts of carbon black, 3 parts of glass air microspheres, 2 parts of reflective heat insulation powder, 3 parts of zinc phosphate, 8 parts of heavy calcium, 18 parts of talcum powder, gas phase dioxide 0.5 parts of silicon, 1.0 parts of organobentonite, 0.1 parts of dispersant (BYK AT203, German BYK), 5 parts of diacetone alcohol, 7 parts of xylene, 10.4 parts of n-butanol; component BI is 50 parts of modified polyamide resin Mixed with 50 parts of methyl isobutyl ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com